Preparation method of PVP modified prussian blue nanometer material

A nanomaterial, Prussian blue technology, applied in the field of preparation of Prussian blue nanomaterials, can solve problems such as harsh conditions, difficult industrial mass production, and limited application, and achieve high quality and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

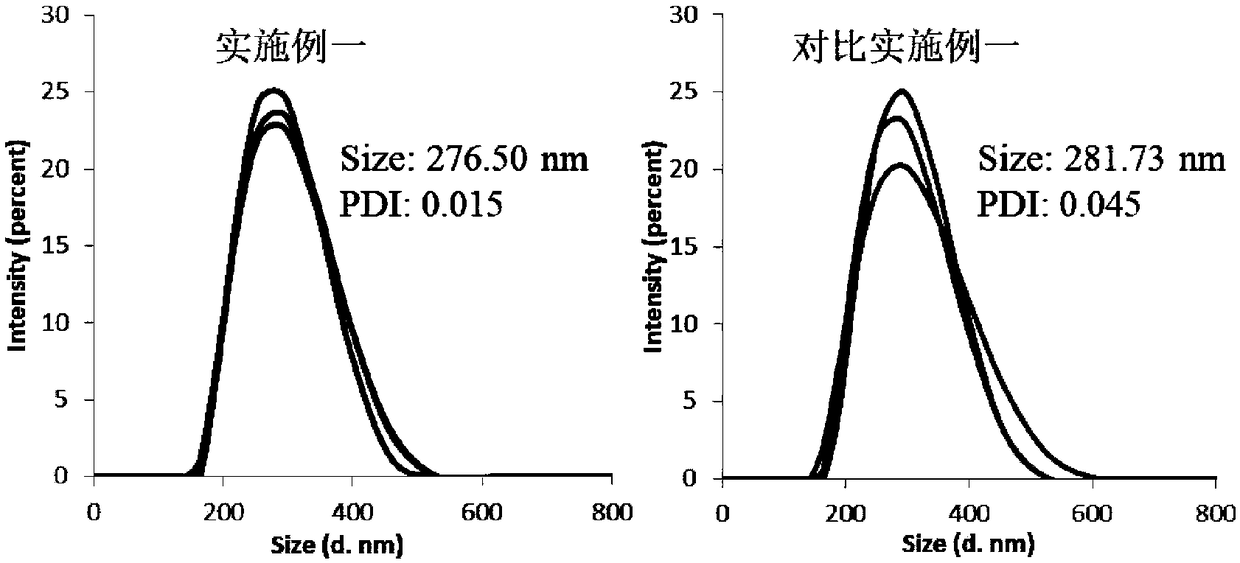

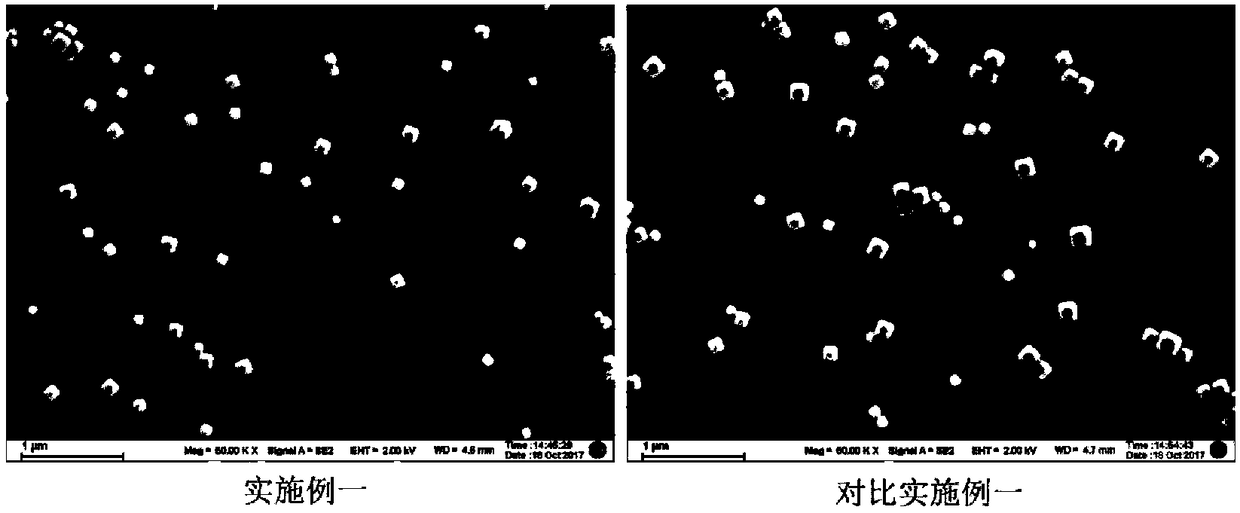

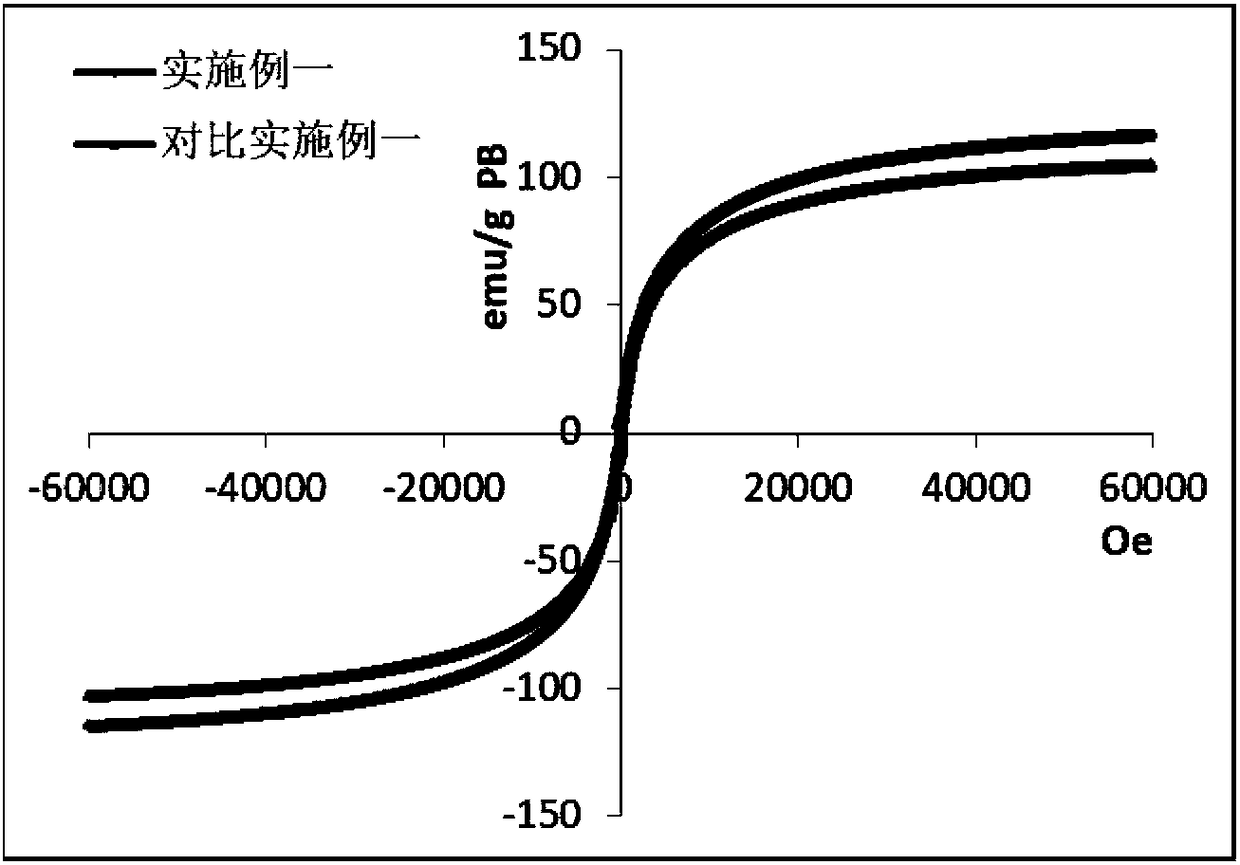

Embodiment 1

[0040] Add polyvinylpyrrolidone K30 (1.5g) and potassium ferricyanide (65mg) into the reaction flask, add 20ml of distilled water, stir to fully dissolve, and the solution becomes clear. Then the pH value was adjusted to 2 with hydrochloric acid to obtain a reaction solution. The reaction solution is placed in the center of the coil of the electromagnetic induction heating device, the frequency of the device is 1355KHz, the maximum power is 6KW, and the diameter of the coil is 3.5cm. Turn on the electromagnetic induction heating equipment to generate an alternating magnetic field, adjust the output current to 11 amperes, and maintain it for 10 hours. Turn off the electromagnetic induction heating equipment, wait for the reaction system to cool down to room temperature, and wash with ethanol:water (2:1) solution system for 3 times, the centrifugal force is 10000G, and the temperature is 4°C. Then transfer to a dialysis bag (100KDa dialysis bag), and dialyze with ultrapure wate...

Embodiment 2

[0044] Add polyvinylpyrrolidone K30 (3g) and potassium ferricyanide (65mg) into the reaction flask, add 20ml of distilled water, stir to fully dissolve, and the solution becomes clear. Then the pH was adjusted to 2 with hydrochloric acid to obtain a reaction solution. The reaction solution is placed in the center of the coil of the electromagnetic induction heating device, the frequency of the device is 1355KHz, the maximum power is 6KW, and the diameter of the coil is 3.5cm. Turn on the electromagnetic induction heating equipment to generate an alternating magnetic field, adjust the output current to 11 amperes, and maintain it for 10 hours. Turn off the electromagnetic induction heating equipment, wait for the reaction system to cool down to room temperature, and wash with ethanol:water (2:1) solution system for 3 times, the centrifugal force is 10000G, and the temperature is 4°C. Then transfer to a dialysis bag (100KDa dialysis bag), and dialyze with ultrapure water at roo...

Embodiment 3

[0046] Add polyvinylpyrrolidone K30 (1.5g) and potassium ferricyanide (195mg) into the reaction flask, add 20ml of distilled water, stir to fully dissolve, and the solution becomes clear. Then the pH was adjusted to 1 with hydrochloric acid to obtain a reaction solution. The reaction solution is placed in the center of the coil of the electromagnetic induction heating device, the frequency of the device is 380KHz, the maximum power is 10KW, and the diameter of the coil is 3.5cm. Turn on the electromagnetic induction heating equipment to generate an alternating magnetic field, and adjust the output current to 30 amperes for 10 hours. Turn off the electromagnetic induction heating equipment, wait for the reaction system to cool down to room temperature, and wash with ethanol:water (2:1) solution system for 3 times, the centrifugal force is 10000G, and the temperature is 4°C. Then transfer to a dialysis bag (100KDa dialysis bag), and dialyze with ultrapure water at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com