Cobalt-doped MCM-48 catalyst

A technology of MCM-48 and catalyst, which is applied in the field of cobalt-doped MCM-48 catalyst and its preparation, can solve the problems that the catalyst cannot be effectively recovered, the secondary pollution of water and products, and the increase of operating costs, etc., so as to prevent secondary pollution , Eliminate product pollution and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

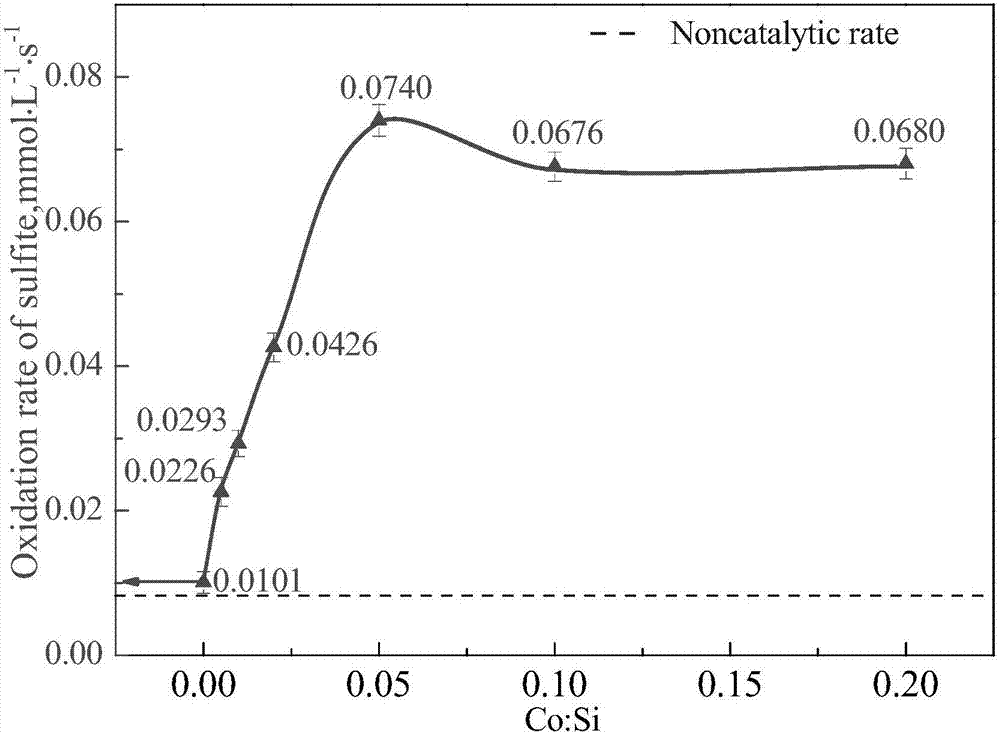

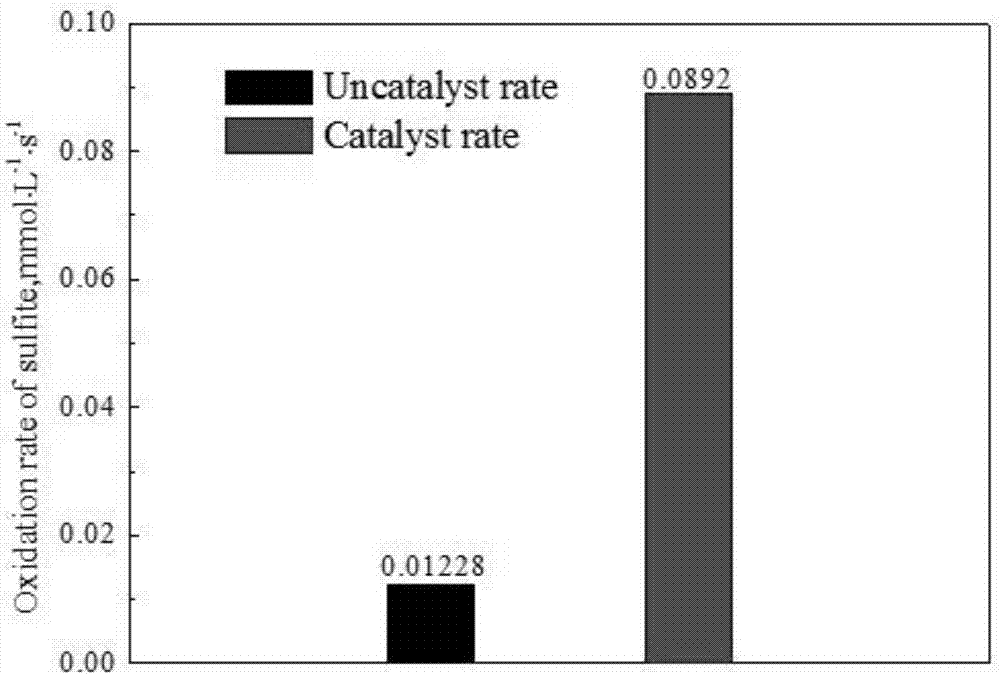

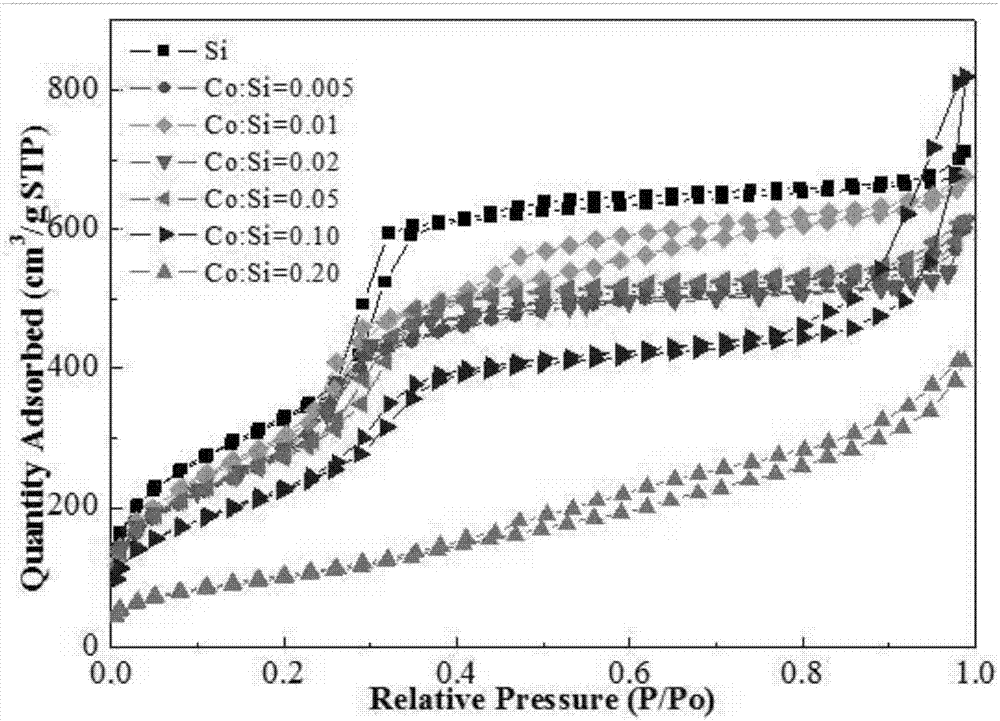

[0021] A cobalt-doped MCM-48 catalyst is a solid-phase catalyst, and transition metal cobalt is incorporated into the framework of MCM-48, wherein the ratio of cobalt to silicon is 0.025-0.075:0.9-1, preferably 0.05:0.95.

[0022] Its preparation method comprises the following steps:

[0023] Dissolve sodium hydroxide in deionized water, then add CTAB to the above sodium hydroxide solution, and at the same time perform magnetic stirring in a water bath environment at 40°C. After stirring evenly, add tetraethyl orthosilicate dropwise in sequence And cobalt nitrate solution, the reaction time is 2 hours; after the reaction is completed, the product is poured into a high-pressure reactor, and crystallized at a constant temperature at 100 ° C for three days. Once, filter with suction, dry at 90°C for 24 hours, and finally calcine at 550°C for 6 hours to obtain cobalt-doped MCM-48 mesoporous molecular sieve catalyst.

[0024] The mass ratio of the total reaction material is Co(NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com