Bismuth sulfide based composite visible-light-induced photocatalyst and preparation method thereof

A visible light and catalyst technology, applied in the field of photocatalysis, can solve the problems of reduced catalytic effect, poor chemical stability, and easy to fall off, etc., and achieve the effects of weakening recombination, increasing the degree of bonding, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

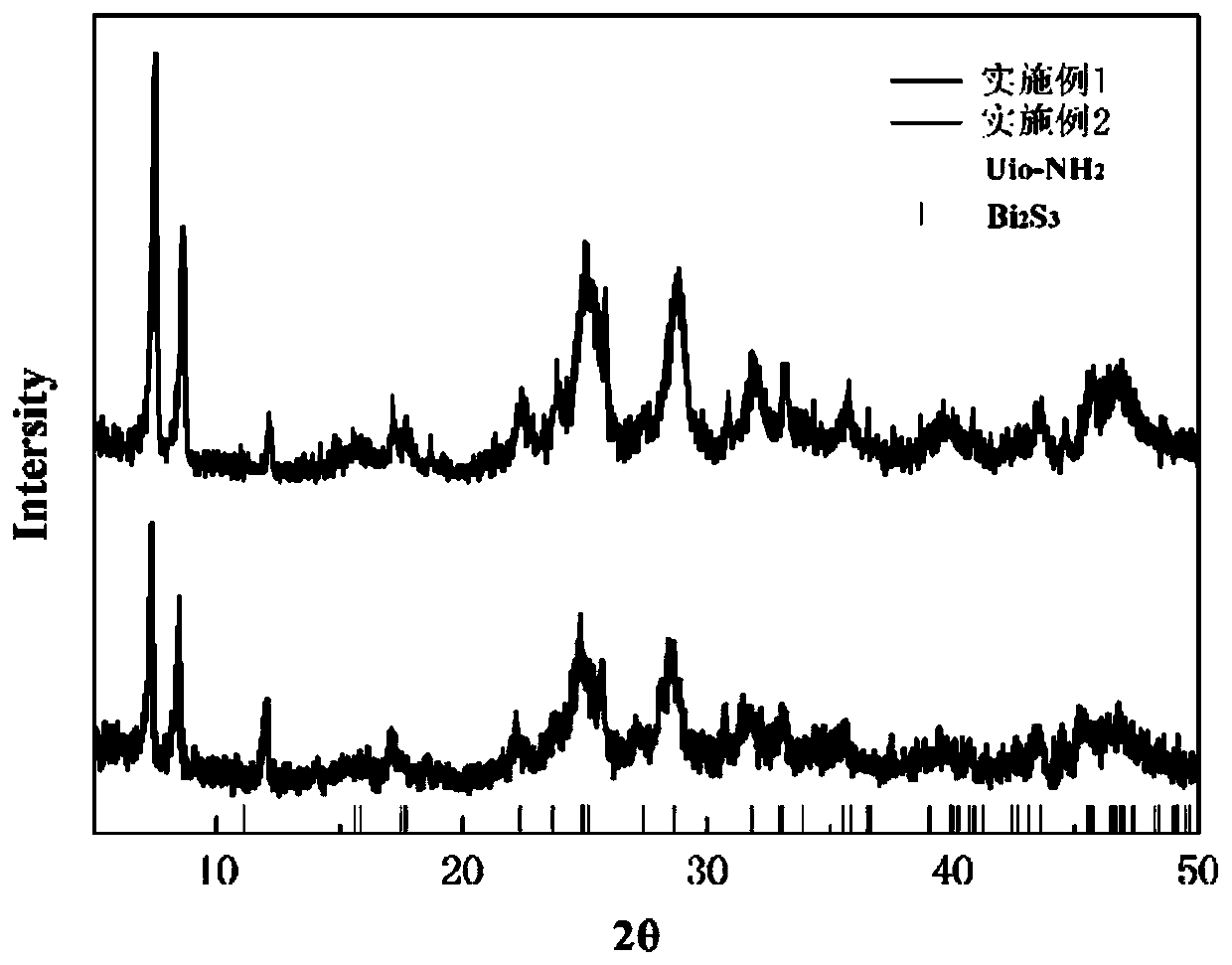

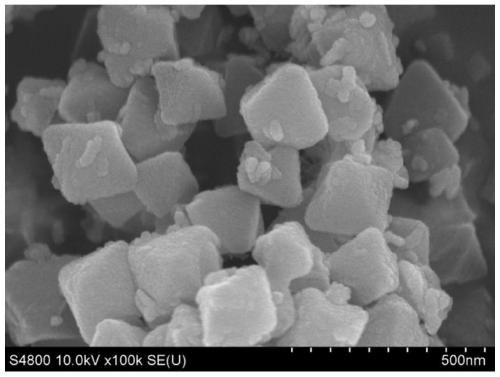

[0022] This embodiment provides a Bi 2 S 3 @UiO-66-NH 2 -The preparation method of the SH-based core-shell structure visible light catalyst, the specific steps are as follows:

[0023] 1) According to ZrCl 4 And the molar ratio of 2-aminoterephthalic acid is 1:1, respectively weigh ZrCl 4 and 2-aminoterephthalic acid, dispersed in N,N-dimethylformamide, then, according to the volume ratio of N,N-dimethylformamide and acetic acid is 10:1, add acetic acid, the reaction temperature The temperature is 120°C, and the reaction time is 24h. After the reaction, cool to room temperature, filter with suction, and alternately wash with N,N-dimethylformamide and deionized water for 1-4 times, dry and grind to obtain UiO-66-NH 2 Matrix material;

[0024] 2) Add UiO-66-NH 2 The matrix material is dispersed in 40ml deionized water, 0.5ml thioglycolic acid is dispersed in 20ml ethanol, and then mixed together and ultrasonicated for 30min;

[0025] 3) According to Bi(NO 3 ) 3 ·5H 2 O...

Embodiment 2

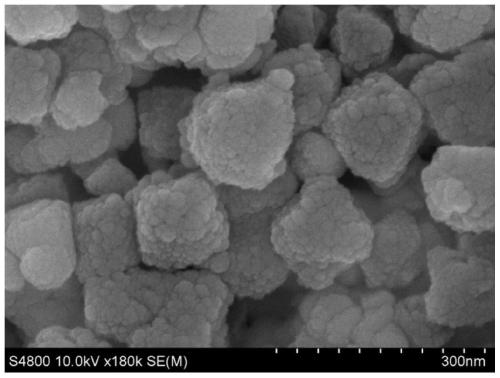

[0028] This embodiment provides a Bi 2 S 3 @UiO-66-NH 2 -The preparation method of the SH-based core-shell structure visible light catalyst, the specific steps are as follows:

[0029] 1) According to ZrCl 4 And the molar ratio of 2-aminoterephthalic acid is 1:1, respectively weigh ZrCl 4 and 2 aminoterephthalic acid, dispersed in N,N-dimethylformamide, then, according to the volume ratio of N,N-dimethylformamide and acetic acid is 10:1, add acetic acid, the reaction temperature is 120°C, the reaction time is 24h. After the reaction, cool to room temperature, filter with suction, and alternately wash with N,N-dimethylformamide and deionized water for 1-4 times, dry and grind to obtain UiO-66-NH 2 Matrix material;

[0030] 2) Add UiO-66-NH 2 The matrix material is dispersed in 40ml of deionized water, 1ml of thioglycolic acid is dispersed in 20ml of ethanol, and then mixed together and ultrasonicated for 30min;

[0031] 3) According to Bi(NO 3 ) 3 ·5H 2 O and UiO-66-N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com