Preparation method and application of erbium-doped zinc cobaltate photocatalyst powder

A technology of photocatalyst and zinc cobaltate, which is applied in the field of photocatalysis, can solve the problems of undiscovered, doped and improved catalytic performance, and achieve the effects of good stability, improved catalytic rate and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

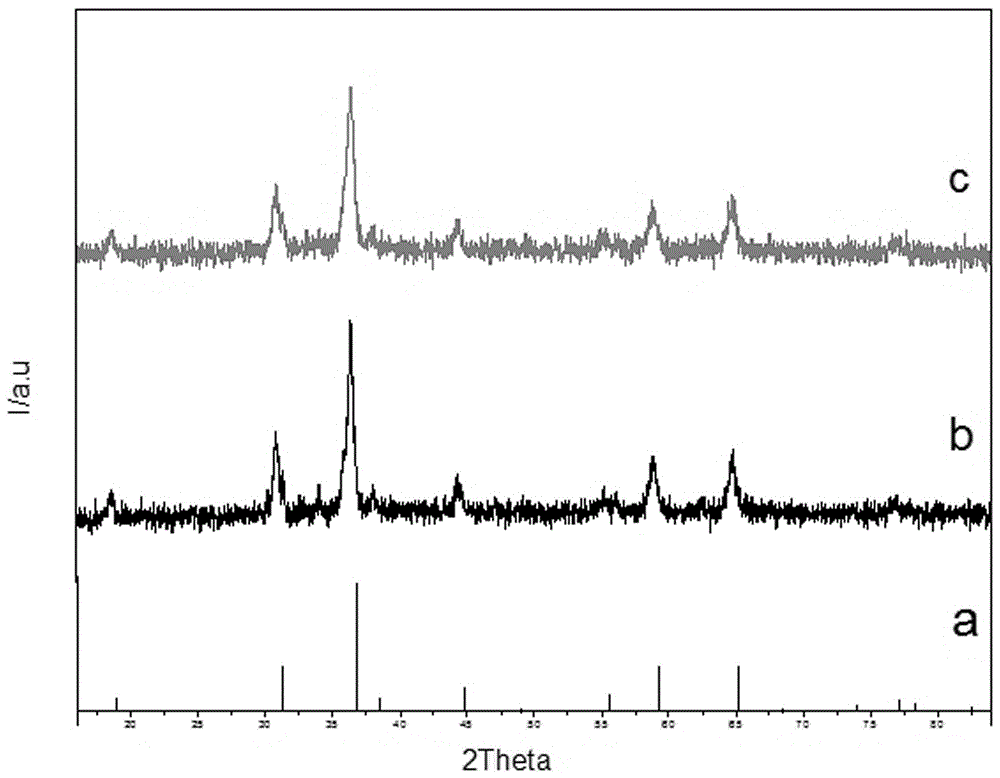

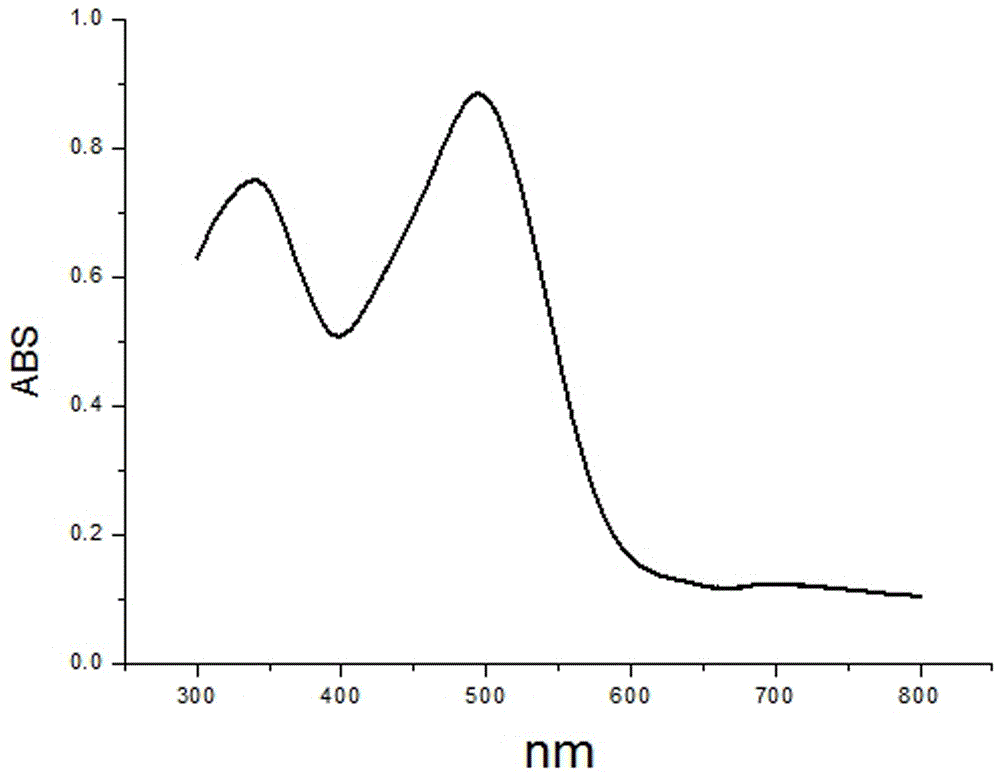

[0034] A kind of erbium-doped zinc cobaltate photocatalyst powder, its general formula is: ZnEr 2x co 2(1-x) o 4 , where x=0.03.

[0035] The preparation method of the erbium-doped zinc cobaltate photocatalyst powder comprises the following steps.

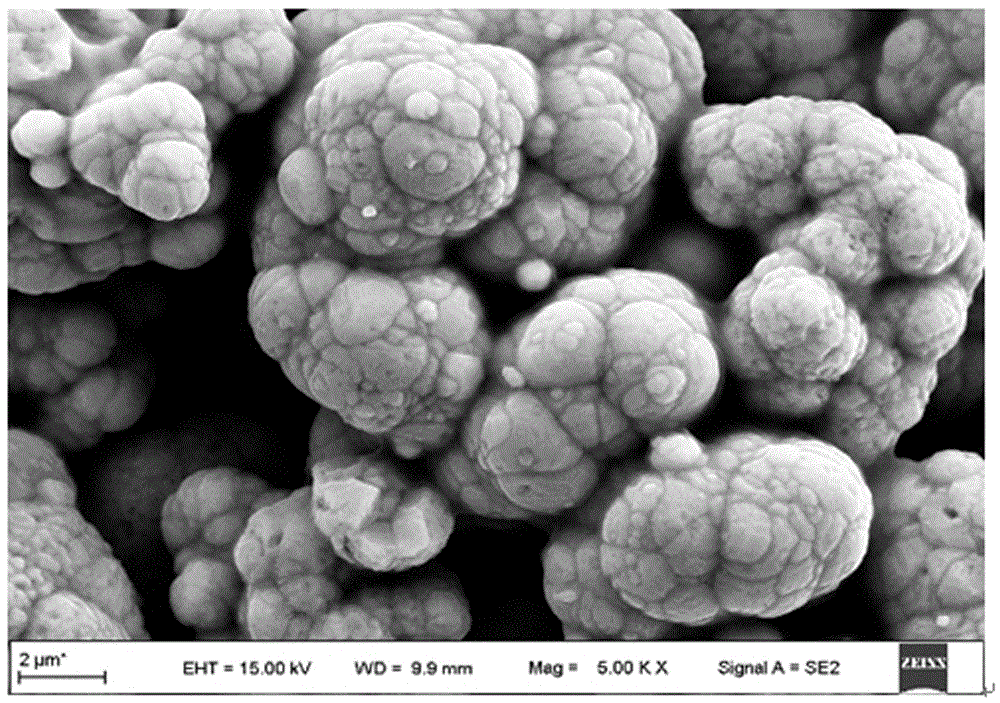

[0036] Weigh 32.3mmol of cobalt acetate and dissolve in 30mL deionized water, stir to prepare a clear A solution, dissolve 16.6mmol of zinc nitrate in 10mL of deionized water, stir to prepare a clear B solution, take 1mmol of erbium acetate and dissolve in 10mL of deionized water In deionized water, stir to prepare a clear C solution. Add solution A and solution C dropwise into solution B, stir and clarify (500r / min), heat at 90°C for 30min. Put the stirred and heated liquid into the oven, keep it warm at 50°C for 5 hours, then put the co-precipitate treated in the oven into the muffle furnace, raise the temperature from room temperature to 250°C for 1h, and then raise the temperature for 1.5h to 700°C Keep it warm for 4 hours...

Embodiment 2

[0039] A kind of erbium-doped zinc cobaltate photocatalyst powder, its general formula is: ZnEr 2x co 2(1-x) o 4 , where x = 0.06.

[0040] The preparation method of the erbium-doped zinc cobaltate photocatalyst powder comprises the following steps.

[0041] Weigh 15.6mmol of cobalt acetate and dissolve it in 30mL deionized water, stir to prepare a clear A solution, take 8.3mmol of zinc nitrate and dissolve it in 10mL of deionized water, stir to prepare a clear B solution, take 1mmol of erbium acetate and dissolve it in 10mL of deionized water In deionized water, stir to prepare a clear C solution. Add solution A and solution C dropwise into solution B, stir and clarify (600r / min), heat at 80°C for 40min. Put the stirred and heated liquid into the oven, keep it warm at 60°C for 4 hours, then put the co-precipitate treated in the oven into the muffle furnace, raise the temperature from room temperature to 500°C for 3h, and then raise the temperature to 700°C for 1.5h Keep ...

Embodiment 3

[0044] A kind of erbium-doped zinc cobaltate photocatalyst powder, its general formula is: ZnEr 2x co 2(1-x) o 4 , where x = 0.03.

[0045] The preparation method of the erbium-doped zinc cobaltate photocatalyst powder comprises the following steps.

[0046] Weigh 16.2mmol of cobalt acetate and dissolve in 20mL deionized water, stir to prepare a clear A solution, dissolve 8.3mmol of zinc nitrate in 20mL of deionized water, stir to prepare a clear B solution, take 0.5mmol of erbium acetate and dissolve in 20mL of In deionized water, stir to prepare a clear C solution. Add solution A and solution C dropwise into solution B, stir and clarify (500r / min), and heat at 60°C for 50min. Put the stirred and heated liquid into the oven, keep it warm at 70°C for 2.5 hours, then put the co-precipitate treated in the oven into the muffle furnace, raise the temperature from room temperature to 350°C for 2 hours, and then raise the temperature to 800°C for 2 hours Keep it warm for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com