Photoelectrocatalytic metal-supported boron-doped diamond, and preparation method and application thereof

A metal-loaded, photoelectric catalysis technology, used in the field of boron-doped diamond and its preparation, can solve the problems of weak catalytic ability and poor stability of electrode materials, and achieve the effects of improving selectivity and efficiency, large specific surface area and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention provides a method for preparing a photoelectrocatalytic metal-loaded boron-doped diamond, comprising the following steps:

[0034] S01. Provide boron-doped diamond as a carrier, the boron-doped diamond includes a substrate, and a boron-doped diamond layer arranged on any side of the substrate;

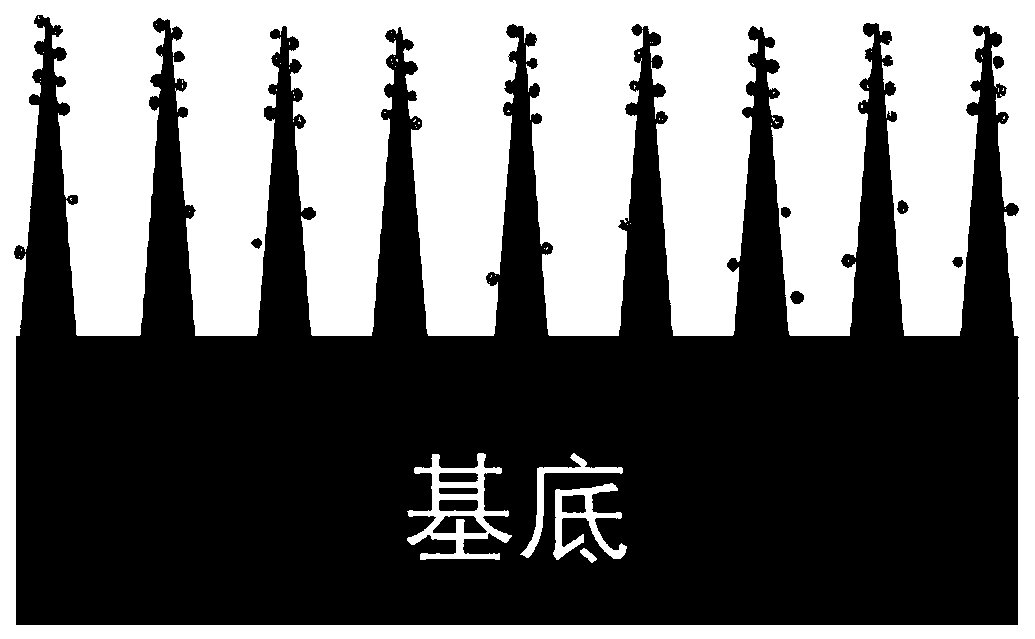

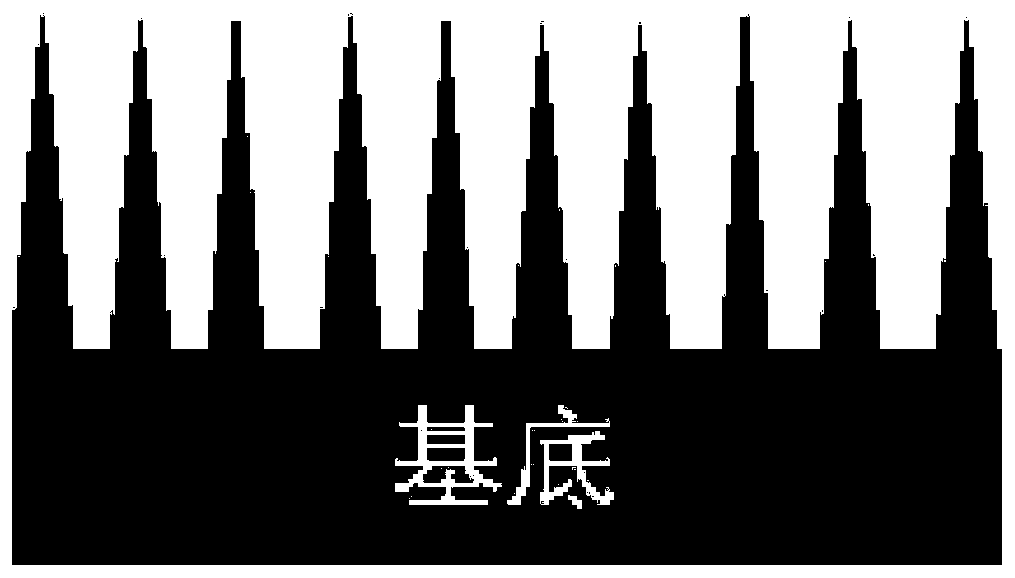

[0035] S02. Perform etching treatment on the surface of the boron-doped diamond layer on any side of the substrate to obtain a processed boron-doped diamond layer, which includes a flat bottom layer and a layer perpendicular to the Flatten the bottom layer of the tapered structure;

[0036] S03. Provide a metal target, and perform metal sputtering treatment on the surface of the boron-doped diamond carrier by means of magnetron sputtering to obtain the photoelectrocatalytic boron-doped diamond loaded with metal.

[0037] Specifically, in step S01 , a substrate is provided. Preferably, the material of the substrate is selected from any mat...

Embodiment 1

[0063] The preparation method of boron-doped diamond loaded with gold by photocatalysis is as follows:

[0064] Step 1: providing a boron-doped diamond carrier, the boron-doped diamond carrier includes a substrate, and a boron-doped diamond layer disposed on either side of the substrate;

[0065] First, provide a substrate of chromium sheet material, and pretreat the substrate: put the substrate in a beaker, add 100mL of hydrogen peroxide solution and 10mL of concentrated sulfuric acid, and sonicate for 30min; wash it with water after sonication, and then add 50mL of acetone, ultrasonic for 10min; then replace the acetone with ethanol, ultrasonic for 10min, remove impurities on the surface of the chromium substrate through two ultrasonic steps, and at the same time form certain defects on the surface, forming crystal planting sites. Then take out the chromium sheet and place it in deionized water for ultrasonic cleaning for 10 min. Finally, the cleaned substrate is placed in ...

Embodiment 2

[0071] The photocatalytic gold-loaded boron-doped diamond prepared in Example 1 is used as an electrode to carry out the photoelectrocatalytic nitrogen reduction reaction as follows: Figure 4 ,Specific steps are as follows:

[0072] A closed double-cell reactor is used, and the working electrode chamber and the counter electrode chamber are separated by glass sheets, so that electrons can pass through, but the solution is prevented from mixing. The prepared diamond film electrode was used as the working electrode, the Pt sheet electrode was used as the counter electrode, and the distance between the working electrode and the counter electrode was 2 cm. Add deionized aqueous solution to the working electrode compartment, and add an equal volume of 0.1M KI solution to the counter electrode compartment. Before starting the reaction, pre-flow N in the working electrode chamber for 0.5 h 2 , and then continue to feed N 2 . The working electrode was irradiated with Hg / Xe arc li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com