Polymerization kettle feeding device and using method thereof

A technology of a polymerization kettle and a feeding end is applied in the field of the feeding device of the polymerization kettle, which can solve the problems of low utilization rate of the polymerization kettle, poor stability of the polyvinyl chloride resin, long feeding time, etc., and avoid high polymerization degree of the polyvinyl chloride resin. , The effect of reducing the width of molecular weight distribution and saving feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

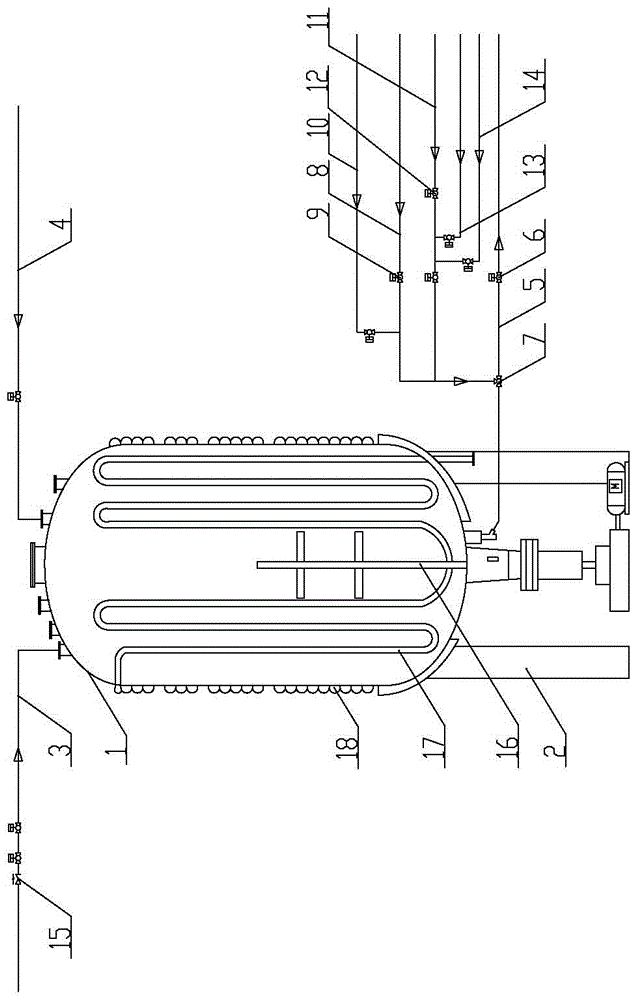

[0023] Embodiment 1, as attached figure 1 As shown, the feed device for the polymerization kettle includes a polymerization kettle 1 and a base 2; A monomer pipeline 3 is fixedly connected to a feed end, a terminator pipeline 4 is fixedly connected to a second feed end, a discharge end is provided at the bottom of the polymerization kettle 1, and a discharge end is fixedly connected to a discharge end. Pipeline 5, a first control valve 6 is fixedly installed on the discharge pipeline 5, a tee 7 is fixedly installed on the discharge pipeline 5 between the polymerization kettle 1 and the first control valve 6, and a tee 7 is fixedly connected to the tee 7 The hot ion-free water pipeline 8, the second control valve 9 is fixedly installed on the hot ion-free water pipeline 8, and the initiator is fixedly connected to the hot ion-free water pipeline 8 between the tee 7 and the second control valve 9 Pipeline 10 and cold deionized water pipeline 11, the third control valve 12 is...

Embodiment 2

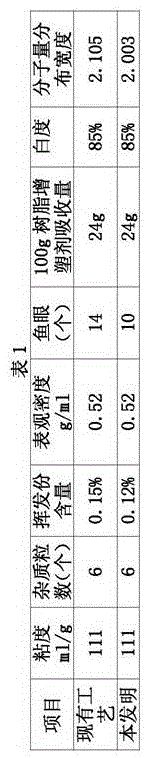

[0029] Embodiment 2, as attached figure 1 As shown, the use method of the feed device of the polymerization kettle is carried out according to the following steps: the first step is to smear the anti-sticking agent on the inner wall of the polymerization kettle, and the pressure in the polymerization kettle is controlled to be -0.07MPa to -0.05MPa; the second Step, add 190 parts to 200 parts of cold deionized water by weight in the polymerization kettle through the cold deionized water pipeline, add 8.75 to 10.5 parts by weight in the polymerization kettle through the dispersant pipeline, and the concentration is 4 % aqueous solution of dispersant, add 1 part to 1.5 parts of aqueous buffer solution with a concentration of 10% by weight to the polymerization tank through the buffer pipeline, so that the cold deionized water enters with the aqueous solution of dispersant and the aqueous solution of buffer In the polymerization kettle, add 410 to 420 parts of vinyl chloride mo...

Embodiment 3

[0030] Embodiment 3, as attached figure 1 As shown, the use method of the polymerization kettle feeding device is carried out according to the following steps: the first step is to apply anti-sticking agent on the inner wall of the polymerization kettle, and the pressure in the polymerization kettle is controlled to be -0.07MPa or -0.05MPa; the second Step, add 190 parts or 200 parts of cold deionized water in the polymerization kettle by parts by weight through the cold deionized water pipeline, add 8.75 parts or 10.5 parts by weight in the polymerization kettle through the dispersant pipeline with a concentration of 4 % aqueous solution of dispersant, add 1 part or 1.5 parts of aqueous buffer solution with a concentration of 10% by weight to the polymerization tank through the buffer pipeline, so that the cold deionized water enters with the aqueous solution of dispersant and the aqueous solution of buffer In the polymerization kettle, add 410 parts or 420 parts of vinyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com