Environment-friendly degradable edible film packaging material

A technology for packaging materials and edible films, applied in the field of food packaging materials, can solve problems such as harming human health, and achieve the effects of preventing water loss, strong mechanical strength and elasticity, and good barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

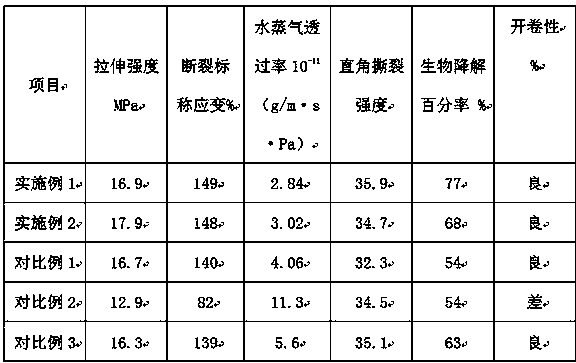

Examples

Embodiment 1

[0023] An environmentally friendly degradable edible edible film packaging material, consisting of 59 parts of modified starch, 37 parts of dandelion extract, 14 parts of konjac gum powder, 48 parts of edible gelatin, 33 parts of modified casein, and carboxymethyl cellulose 12 parts, chitosan 6 parts, plasticizer 4 parts, agar 9 parts, citric acid 2 parts, antibacterial liquid 3 parts, plant extract 1 part, cactus juice 3 parts, glutinous rice juice 5 parts, carrot powder 3 parts.

[0024] An environmentally friendly degradable edible film packaging material, the preparation method of which comprises the following steps: (1) accurately weighing the raw materials of each component; (2) homogenizing: mixing modified starch, dandelion extract, konjac gum powder, edible The gelatin is mixed and placed in a homogenizer to fully mix; (3) sieving: After homogenizing with a fine sieve, select a 60-80 mesh sieve to sieve the fine whey to obtain the initial mixed whey; (4) Fibrosis adjus...

Embodiment 2

[0032] An environmentally friendly degradable edible film packaging material, which consists of 69 parts of modified starch, 51 parts of dandelion extract, 14 parts of konjac gum powder, 41 parts of edible gelatin, 23 parts of modified casein, and carboxymethyl cellulose 13 parts, chitosan 6 parts, plasticizer 7 parts, agar 12 parts, citric acid 2 parts, antibacterial liquid 3 parts, plant extract 1 part, cactus juice 3 parts, glutinous rice juice 4 parts, carrot powder 5 parts.

[0033] An environmentally friendly degradable edible film packaging material, the preparation method of which comprises the following steps: (1) accurately weighing the raw materials of each component; (2) homogenizing: mixing modified starch, dandelion extract, konjac gum powder, edible The gelatin is mixed and placed in a homogenizer to fully mix; (3) sieving: After homogenizing with a fine sieve, select a 60-80 mesh sieve to sieve the fine whey to obtain the initial mixed whey; (4) Fibrosis adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com