Fiber reinforced artificial stone tomb box and its manufacturing method

A fiber-reinforced, manufacturing method technology, applied in graves, manufacturing tools, urns, etc., can solve the problems of high cost, poor impact resistance and impermeability, scarcity of resources, etc. A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

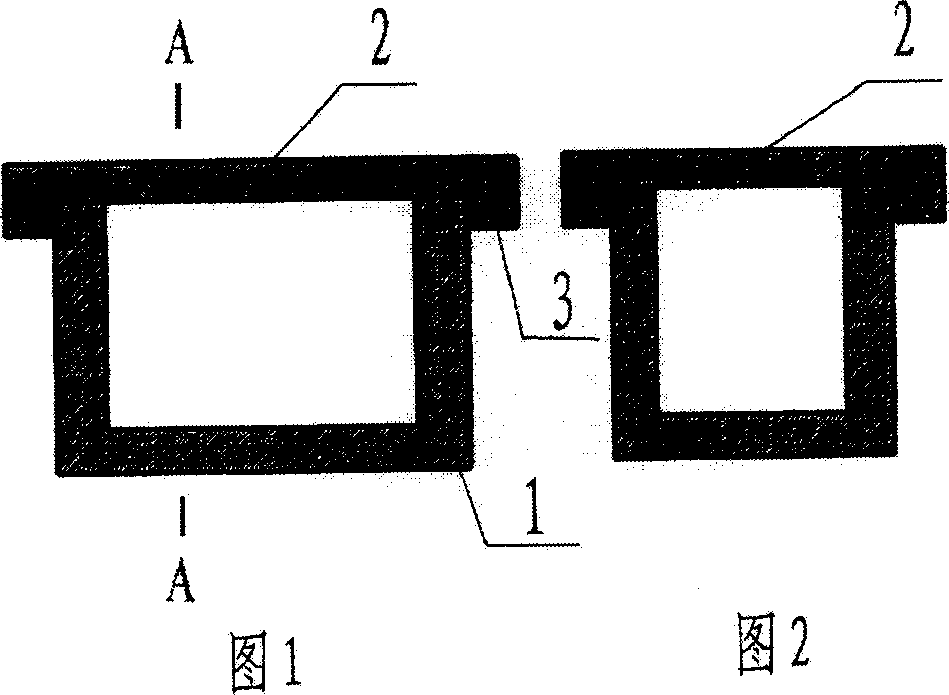

[0030] Embodiment 1 Referring to Fig. 1 and Fig. 2, the fiber-reinforced artificial stone tomb box of the present invention has a box body 1 and a case cover 2 made of fiber-reinforced artificial stone, the inside of the box body 1 has a cavity, and the box cover has four sides. The convex edge 3, the inner edge of the lower convex edge coincides with the outer edge 4 of the upper edge of the box body.

Embodiment 2

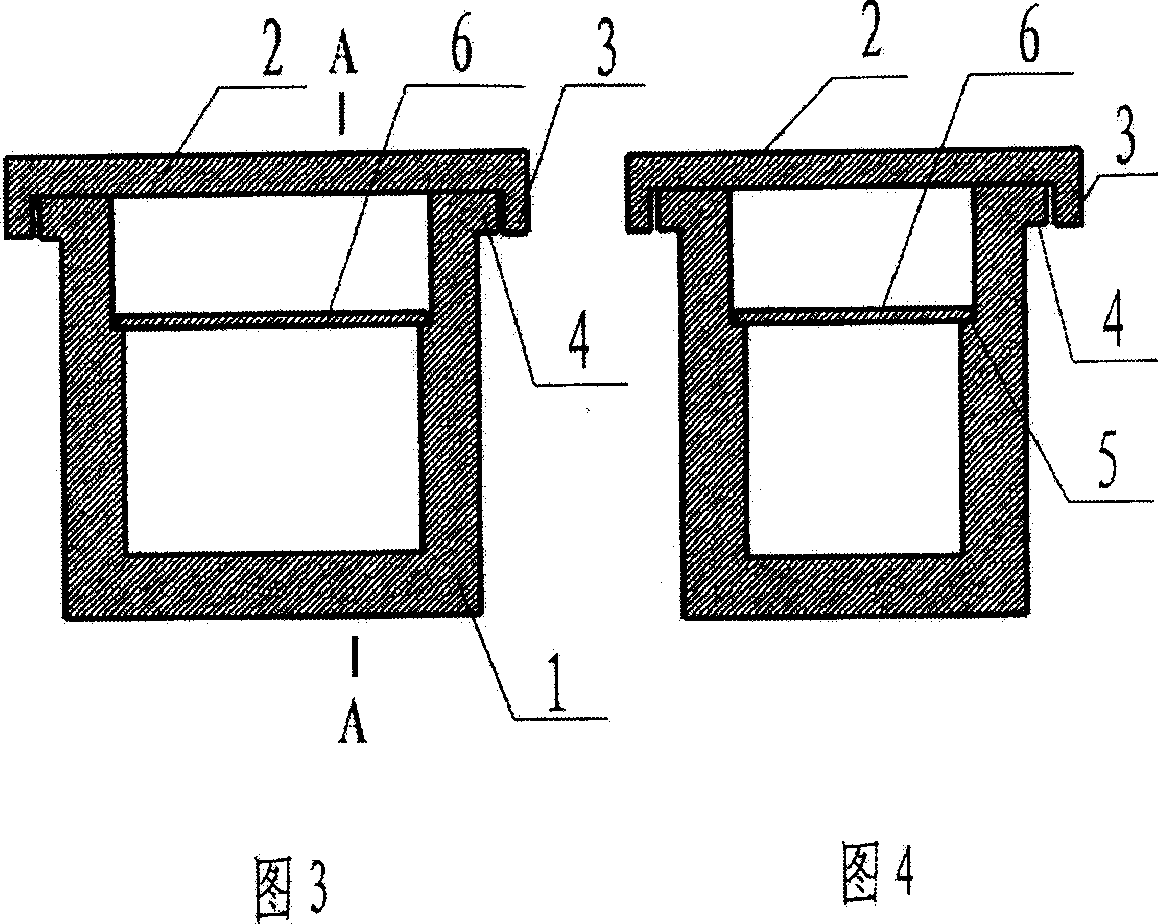

[0031] Embodiment 2 Referring to Fig. 3 and Fig. 4, the outer edge 4 of the upper edge of the above-mentioned box body is horizontally convex toward the outer wall of the box body.

Embodiment 3

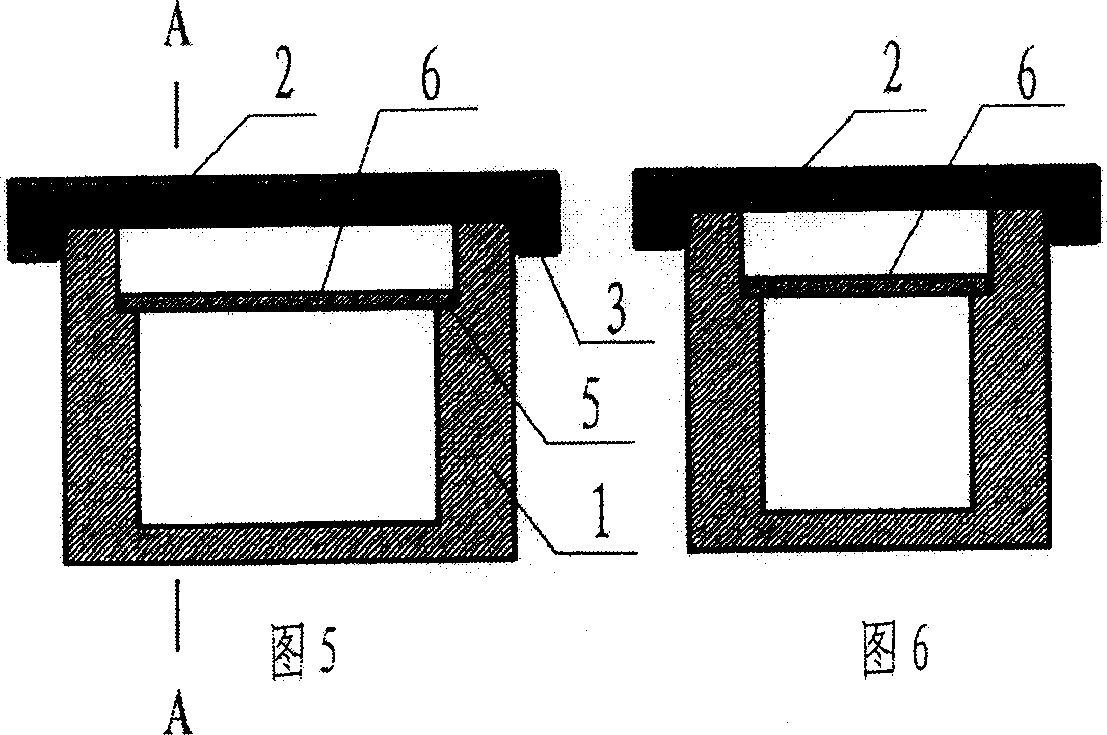

[0032] Embodiment 3 Referring to Fig. 5 and Fig. 6, there is a boss 5 on the inner wall of the above-mentioned box, and a tribute platform 6 is erected on the boss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com