Electromagnetic shielding cement board and semi-dry preparation process thereof

A technology of electromagnetic shielding and preparation technology, which is applied in the field of cement boards, can solve the problems of rising raw material costs, high prices, and high prices of cement boards, and achieve the effects of reducing volume shrinkage and cracking, low porosity, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

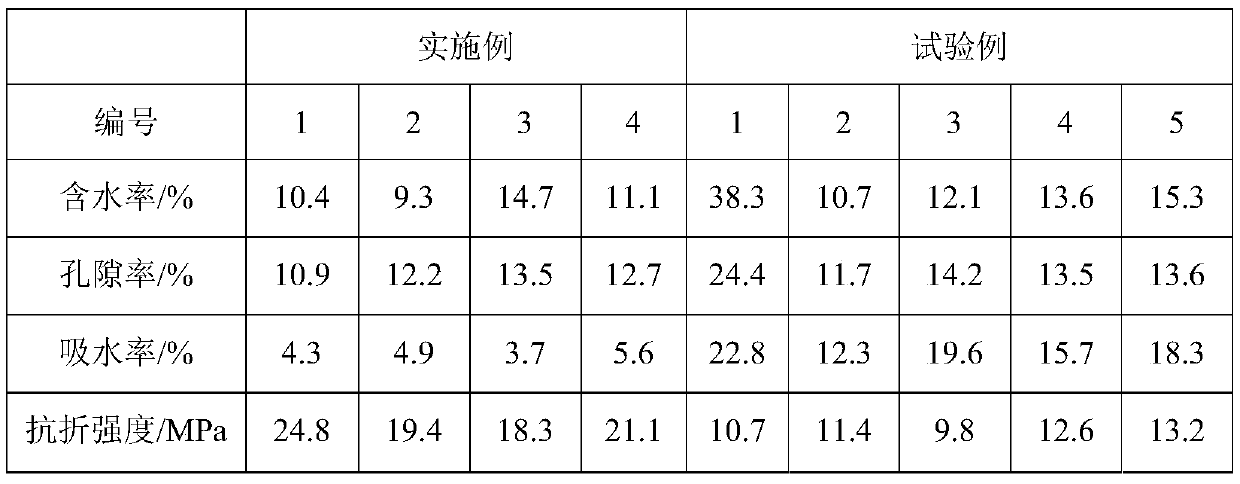

Embodiment 1

[0046] 1. An electromagnetic shielding cement board, comprising material A and solution B. In parts by weight, said material A comprises the following raw materials: 60 parts of Portland cement, 8 parts of glass fiber, 3 parts of silica fume, 12 parts of fly ash Parts, polyvinylpyrrolidone (molecular weight is 2.0×10 4 ) 1.5 parts; the solution B is made up of the following raw materials in parts by weight: 95 parts of water, 3 parts of KH550 type silane coupling agent, ferroferric oxide modified graphene oxide (GO-Fe 3 o 4 ) 0.1 part, wherein; the GO-Fe 3 o 4 The loading amount of ferric oxide in the medium is 5% (mol fraction).

[0047] 2. In the present embodiment, the preparation method of the modified graphene oxide by ferric oxide is as follows: (1) dilute the graphene oxide solution to 0.5mg / ml, then add ferric oxide to graphene oxide in proportion In the solution, the obtained mixed solution was placed in a magnetic stirrer with a water bath heating function and st...

Embodiment 2

[0054] 1. An electromagnetic shielding cement board, comprising material A and solution B. In parts by weight, said material A comprises the following raw materials: 70 parts of Portland cement, 5 parts of glass fiber, 6 parts of silica fume, 5 parts of fly ash Parts, polyvinylpyrrolidone (molecular weight is 3.4×10 4 ) 1.2 parts; the solution B is made up of the following raw materials in weight parts: 98 parts of water, 5 parts of KH550 type silane coupling agent, ferroferric oxide modified graphene oxide (GO-Fe 3 o 4 ) 0.15 parts, wherein; the GO-Fe 3 o 4 The loading amount of ferric oxide in the medium is 2% (mol fraction).

[0055] 2. In the present embodiment, the preparation method of the modified graphene oxide by ferric oxide is as follows: (1) dilute the graphene oxide solution to 0.3 mg / ml, and then add ferric oxide to graphene oxide in proportion In the solution, the obtained mixed solution was placed in a magnetic stirrer with a water bath heating function and...

Embodiment 3

[0062] 1. An electromagnetic shielding cement board, comprising material A and solution B. In parts by weight, said material A comprises the following raw materials: 50 parts of Portland cement, 10 parts of glass fiber, 7 parts of silica fume, and 10 parts of fly ash Parts, polyvinylpyrrolidone (molecular weight is 1.3×10 4 ) 0.5 part; the solution B is made up of the raw materials of following weight parts: 92 parts of water, 6 parts of KH550 type silane coupling agent, ferroferric oxide modified graphene oxide (GO-Fe 3 o 4 )0.05 part, wherein; the GO-Fe 3 o 4 The loading amount of ferric oxide in the medium is 7% (mol fraction).

[0063]2. In the present embodiment, the preparation method of the modified graphene oxide by ferric oxide is as follows: (1) dilute the graphene oxide solution to 0.4 mg / ml, and then add ferric oxide to graphene oxide in proportion In the solution, the obtained mixed solution was placed in a magnetic stirrer with a water bath heating function a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com