Method for preparing high-strength artificial stone from sodium sulfide slag

A technology of sodium sulfide and artificial stone is applied in the field of resource utilization of industrial waste residues to achieve the effects of no secondary pollution, reduced sodium content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific examples.

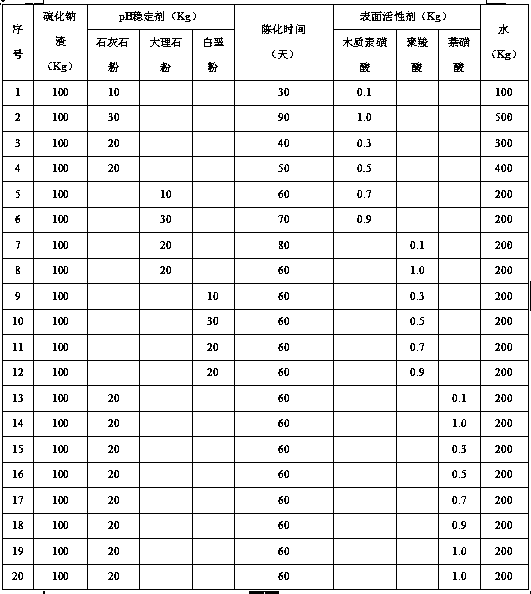

[0023] (1) Add a pH stabilizer and microorganisms to the sodium sulfide slag and age for 30-90 days, then add a surfactant and water, stir evenly, and filter to obtain pretreated sodium sulfide slag. The table below shows 20 examples of sodium sulfide slag pretreatment formula numbers 1-20.

[0024] Table 1

[0025]

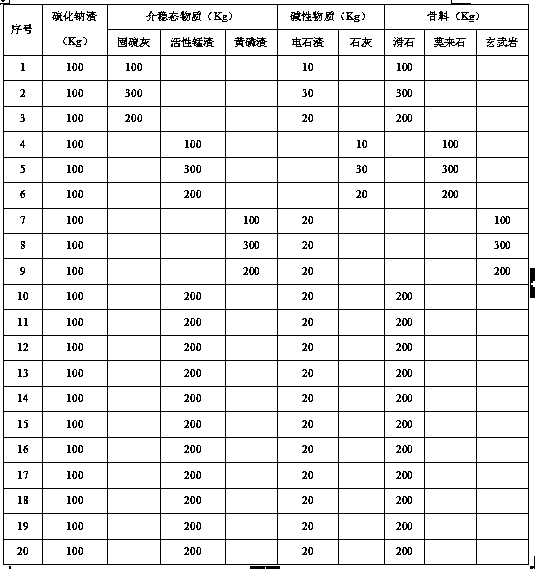

[0026] (2) High-strength artificial stone: Add metastable substances, alkaline substances, and aggregates to the pretreated sodium sulfide slag, mix them evenly, pour them into abrasive tools, press them into shapes, and cure them in water to obtain high-strength artificial stones.

[0027]

[0028] In Example 1-Example 20, the strength of the artificial stone is greater than 30 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com