Method for physical and chemical separation of waste incineration fly ash and preparation of cementing material

A technology of waste incineration fly ash and cementitious materials, which is applied in the field of resource utilization of other wastes and domestic waste incineration fly ash, and can solve the problems of poor working conditions on site, ineffective resource treatment of incineration fly ash, environmental pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

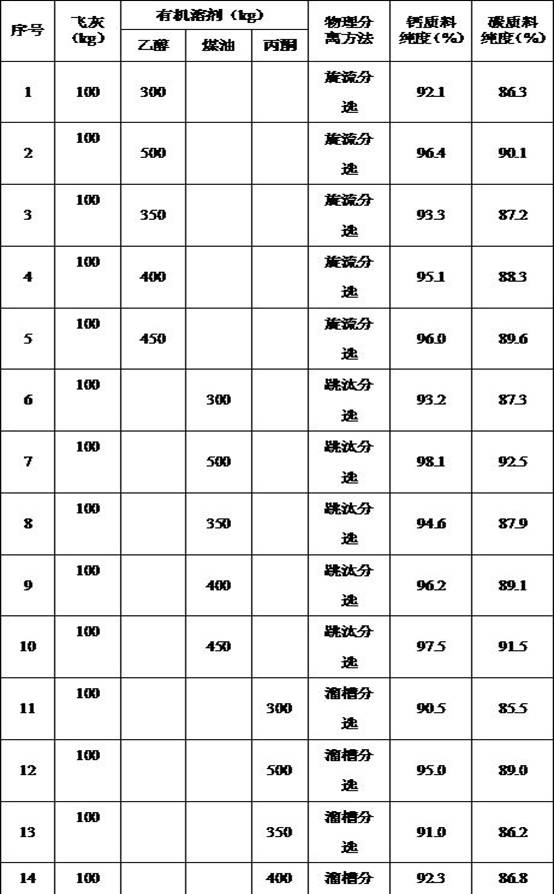

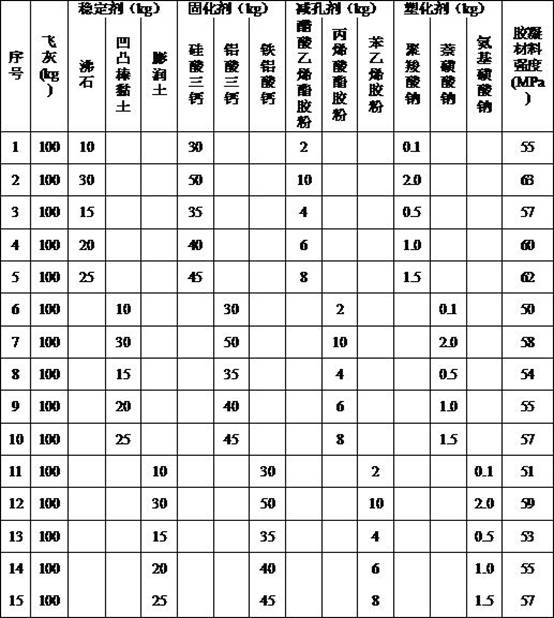

[0026] The present invention will be described in further detail below in conjunction with specific examples.

[0027] Disperse the fly ash in an organic solvent, and obtain calcium raw materials, chlorine raw materials and carbon raw materials through physical separation and filtration; add stabilizers, curing agents, pore reducers, and plasticizers to the calcium raw materials, and mix them uniformly to obtain gelation Materials; water and capture agent are added to the chlorine raw material, and metal slag and chlorine salt solution are obtained by filtration; the carbon raw material is sent to a waste incinerator for combustion and recovery. See Table 1 for organic solvents, physical separation methods, purity of calcium raw materials, and purity of carbon raw materials. Stabilizer, curing agent, porosity reducer, plasticizer formula and strength of cementitious material, see Table 2. See Table 3 for water and capture agent formulations, and different salt separation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com