Preparation method of phosphogypsum-based high-fluidity water-resistant mortar

A high-fluidity, phosphogypsum technology, applied in the field of mortar, can solve the problems that hinder the high-value application of phosphogypsum, poor mortar fluidity, poor water resistance, etc., to improve strength, increase mortar strength, improve strength and water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

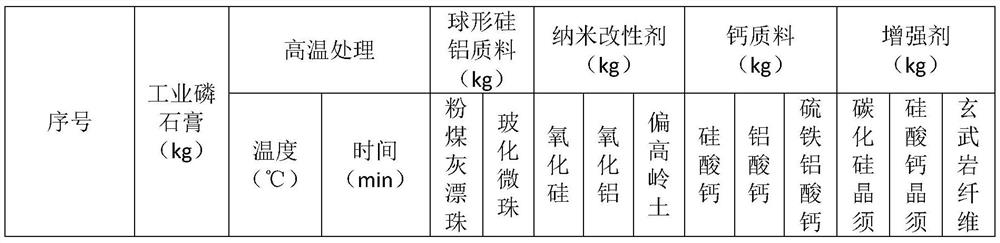

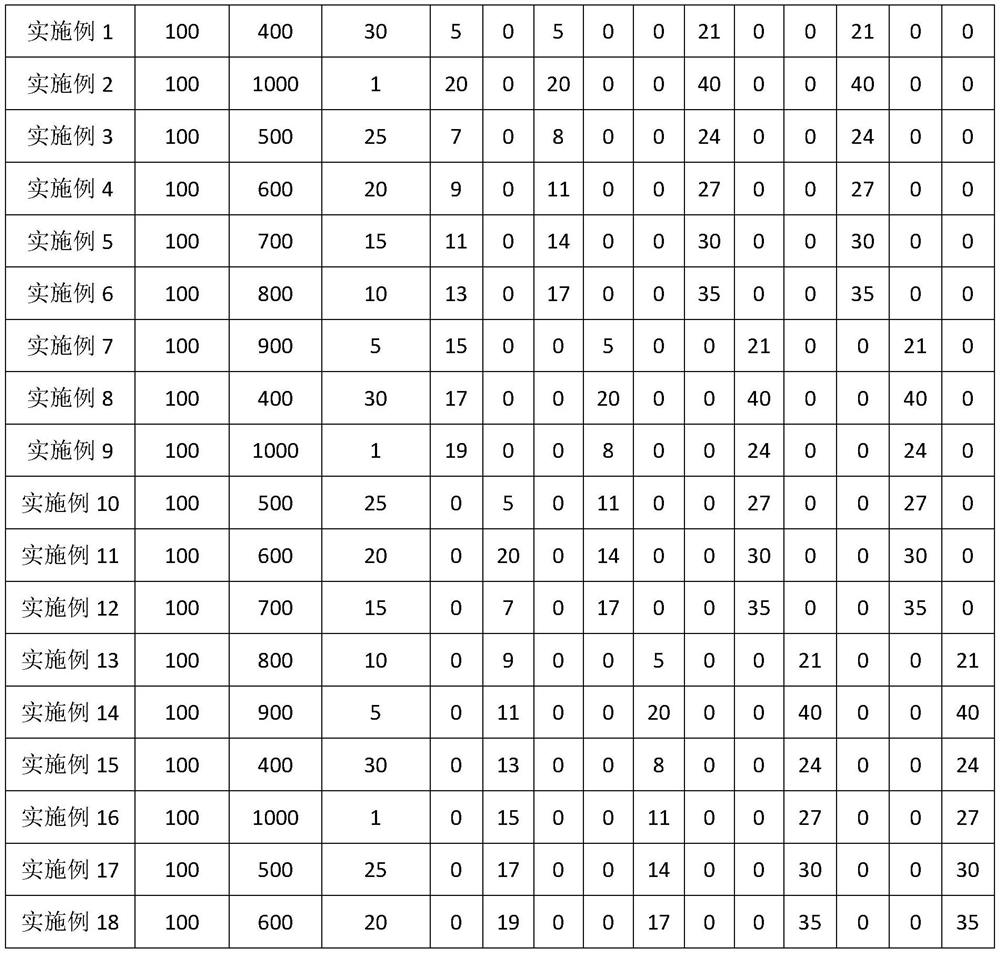

Image

Examples

Embodiment 1

[0041] A preparation method of phosphogypsum-based high-fluidity water-resistant mortar, comprising the following steps:

[0042] Step 1, chemical shaping of industrial phosphogypsum: Add industrial phosphogypsum to the electrolyte solution containing succinic acid and metal cations, the metal cations are iron ions provided by ferric sulfate, and the electrolyte solution is sodium chloride solution. Under the same conditions, crystallize for 80 minutes to obtain phosphogypsum with equiaxed grains; the aspect ratio, aspect ratio or aspect ratio of the obtained equiaxed gypsum grains are all less than 1.5; the addition of succinic acid is 0.2kg, iron sulfate The addition amount of 0.3kg;

[0043] Step 2, high temperature treatment: treat phosphogypsum at a temperature of 400-1000°C for 1-30 minutes to obtain inert phosphogypsum;

[0044] Step 3: Add spherical silica-alumina raw materials, nano-powder materials, calcium raw materials, reinforcing agents, flow enhancers, water-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com