High-water-pressure super-large-diameter underwater shield tunnel double-liquid grouting slurry, process and application

A super-diameter, shield tunneling technology, used in tunnels, tunnel linings, underground chambers, etc., can solve the problems of poor strength and toughness, low mud water retention rate, poor filling effect, etc., to improve strength and improve impermeability. performance, the effect of increasing fill retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

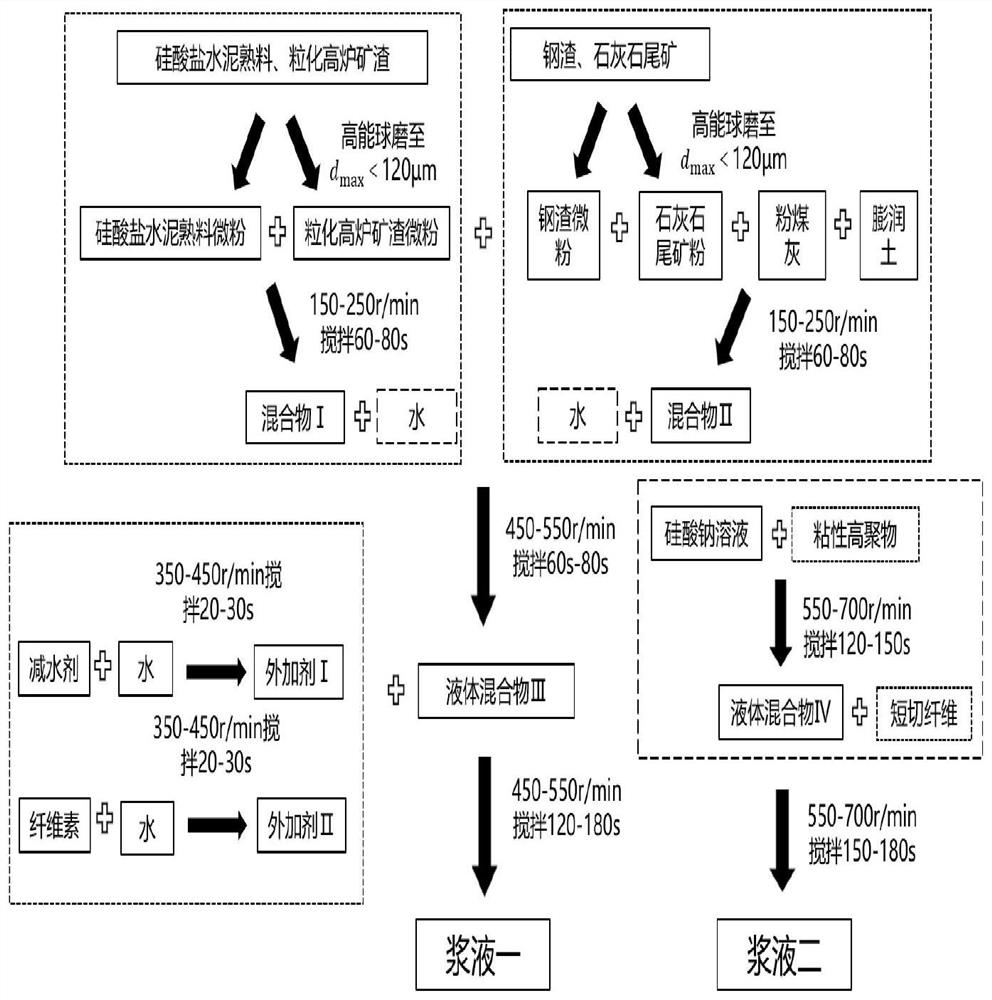

Method used

Image

Examples

Embodiment 1

[0074] A double-liquid grouting slurry for super-large-diameter underwater shield tunneling under high water pressure, which is composed of slurry one and slurry two, and the slurry one is made of the following raw materials in parts by weight: Portland cement clinker 42 parts; granulation 22 parts of blast furnace slag; 30 parts of fly ash; 21 parts of steel slag; 8 parts of bentonite; 7 parts of limestone tailings; 1 part of water reducing agent; Raw materials in parts by weight: 3 parts of chopped fiber; 98 parts of sodium silicate solution; 3.5 parts of viscous high polymer. The water reducer is a mixture of naphthalene-based water reducer and polycarboxylate water reducer with a mass ratio of 3:2, and the chopped fibers are chopped basalt fibers and chopped polypropylene with a mass ratio of 2:1. A mixture of fibers, the viscous high polymer is a mixture of acrylate polymer, ethylene-vinyl acetate copolymer and polyvinyl alcohol in a mass ratio of 1:1.5:1.

[0075] The p...

Embodiment 2

[0107] A double-liquid grouting slurry for super-large-diameter underwater shield tunneling with high water pressure, which is composed of slurry 1 and slurry 2, wherein the water reducing agent is polycarboxylate water reducing agent, the cellulose is hydroxypropyl methylcellulose, and the The cut fibers are chopped basalt fibers, and the viscous high polymer is an acrylate polymer, and the same as in Example 1 except that.

[0108] The preparation process of the double liquid grouting slurry is the same as in Example 1.

[0109] The slurry one and the slurry two are mixed according to the volume ratio of 5:1, and the performance of the mixed double slurry is tested according to the method of embodiment 1, and the results are shown in table 4 below:

[0110]

Embodiment 3

[0112] A double-liquid grouting slurry for super-large-diameter underwater shield tunneling with high water pressure, which is composed of slurry 1 and slurry 2, wherein the water reducer is naphthalene-based water reducer, the cellulose is hydroxypropyl methylcellulose, chopped The fiber is a chopped polypropylene fiber, and the viscous high polymer is an ethylene-vinyl acetate copolymer, except that it is the same as in Example 1.

[0113] The preparation process of the double liquid grouting slurry is the same as in Example 1.

[0114] The slurry one and the slurry two are mixed according to a volume ratio of 5:1, and the performance of the mixed double slurry is tested according to the method of Example 1, and the results are shown in Table 5 below:

[0115]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com