Construction method of lowering double-wall special-shaped steel cofferdam

A cofferdam decentralization and construction method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult to guarantee safety, increase the comprehensive cost of construction, and speed up the construction period, so as to ensure safety and smooth progress, enhance anti-overturning ability, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

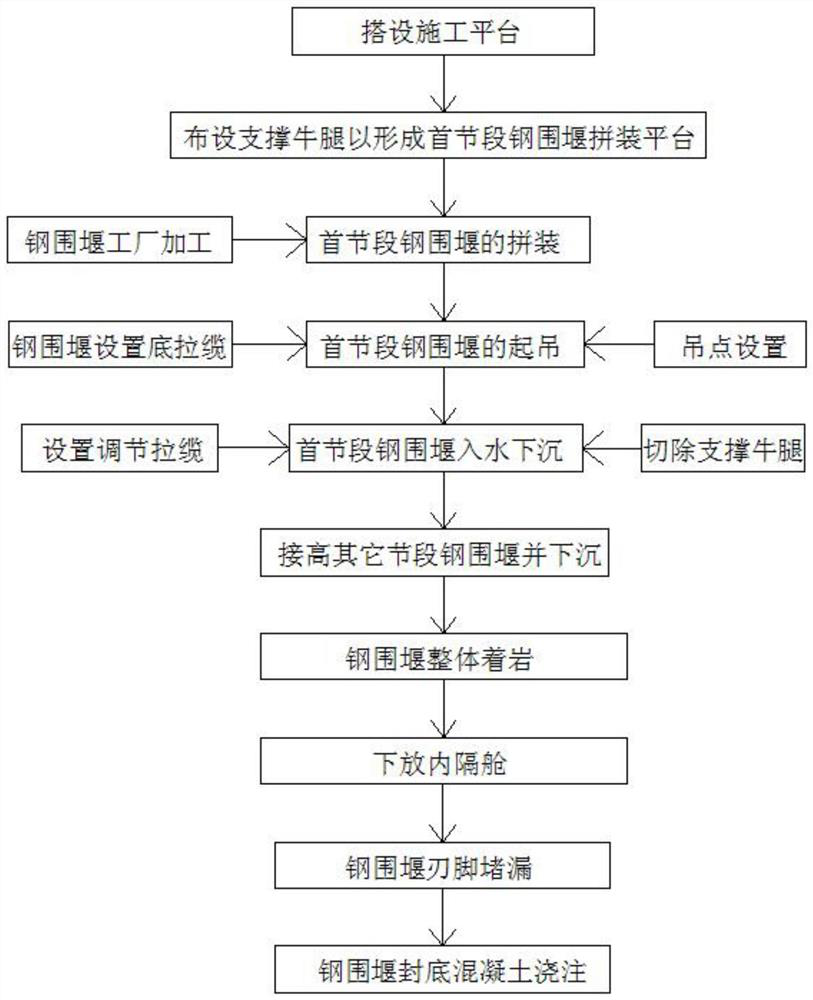

[0041] like Figure 1 to Figure 3 Shown, the double-wall special-shaped steel cofferdam among the present invention puts down construction method, comprises the steps:

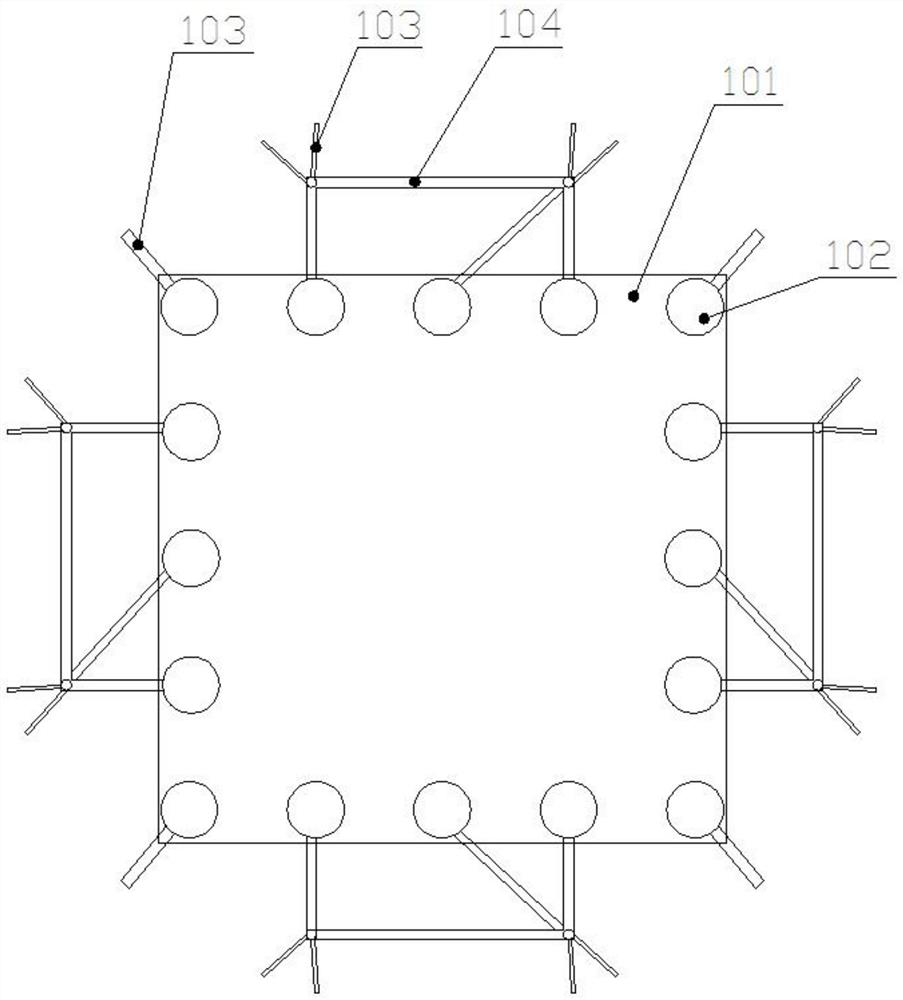

[0042] A. Erection of the steel cofferdam assembly platform in the first section:

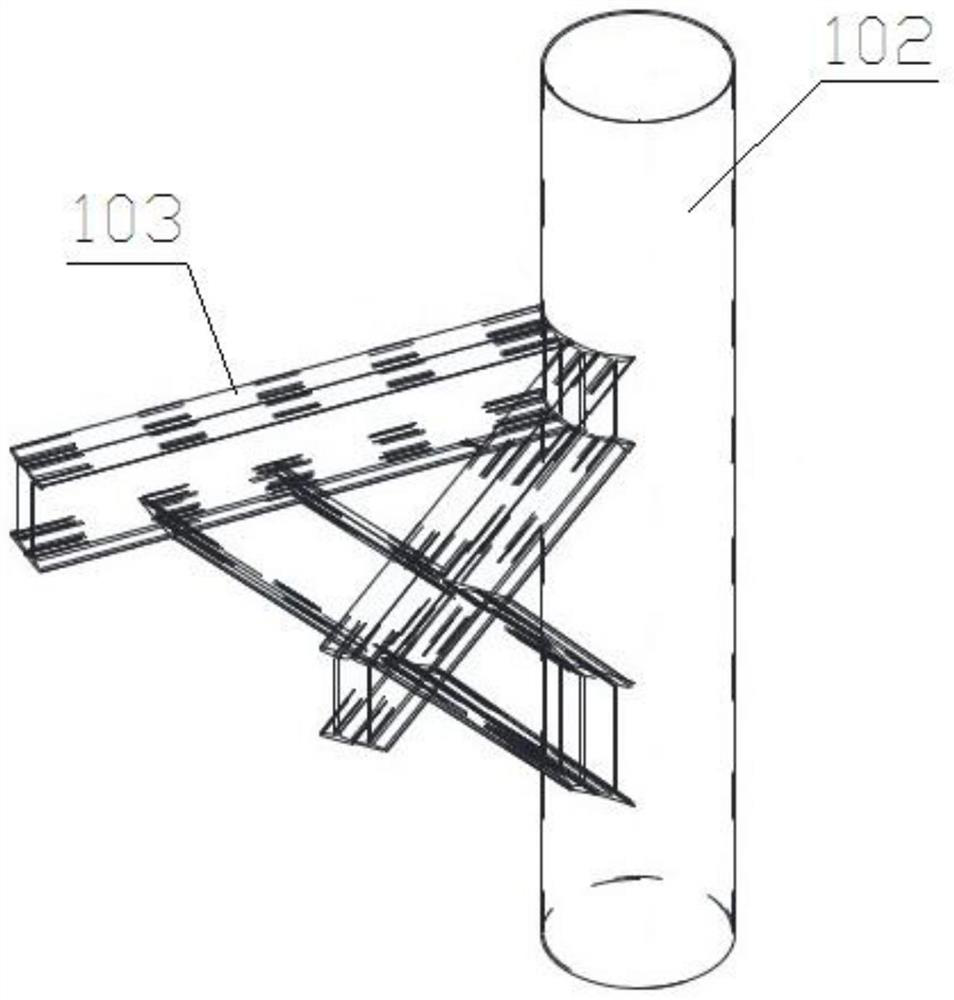

[0043] Set up the construction platform, the construction platform comprises a working platform 101 and a support pile 102, the bottom of the support pile 102 is fixedly arranged on the riverbed in the construction area, and the top is stretched out of the water surface, and the working platform 101 is fixedly arranged on the top of the support pile 102; Supporting corbels 103 are fixedly arranged on the outer side wall of the working platform 101, and the supporting corbels 103 are arranged at intervals around the working platform 101, and the supporting corbels 103 are cantilevered on the supporting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com