High-strength, corrosion-resistant, high-thermal-conductivity, free-cutting, lead-free and environment-friendly silicon brass as well as preparation and application thereof

A high thermal conductivity, easy cutting technology, applied in the field of copper alloy preparation, can solve the problems of lead-free silicon brass difficult and easy cutting performance, dezincification corrosion resistance, high tensile plasticity, high strength and high thermal conductivity, etc., to achieve excellent comprehensive physical and chemical properties Improved performance, tensile strength and plasticity, and improved chip breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

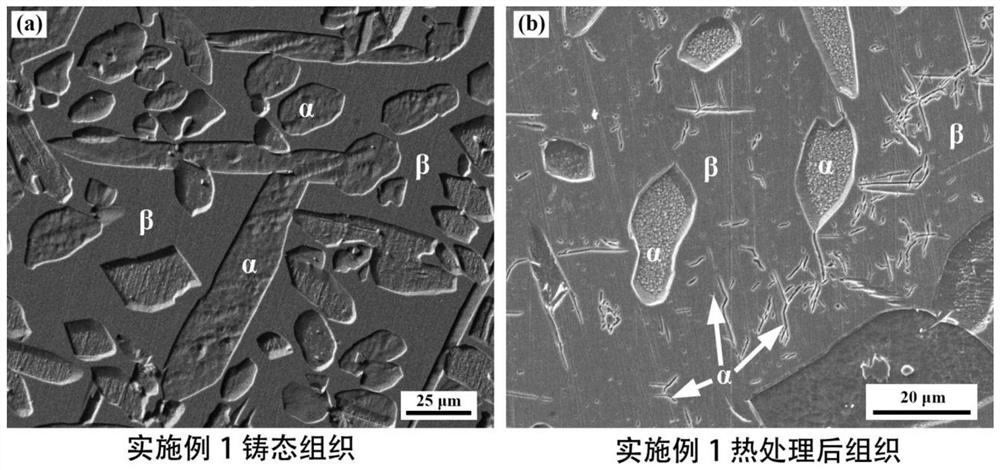

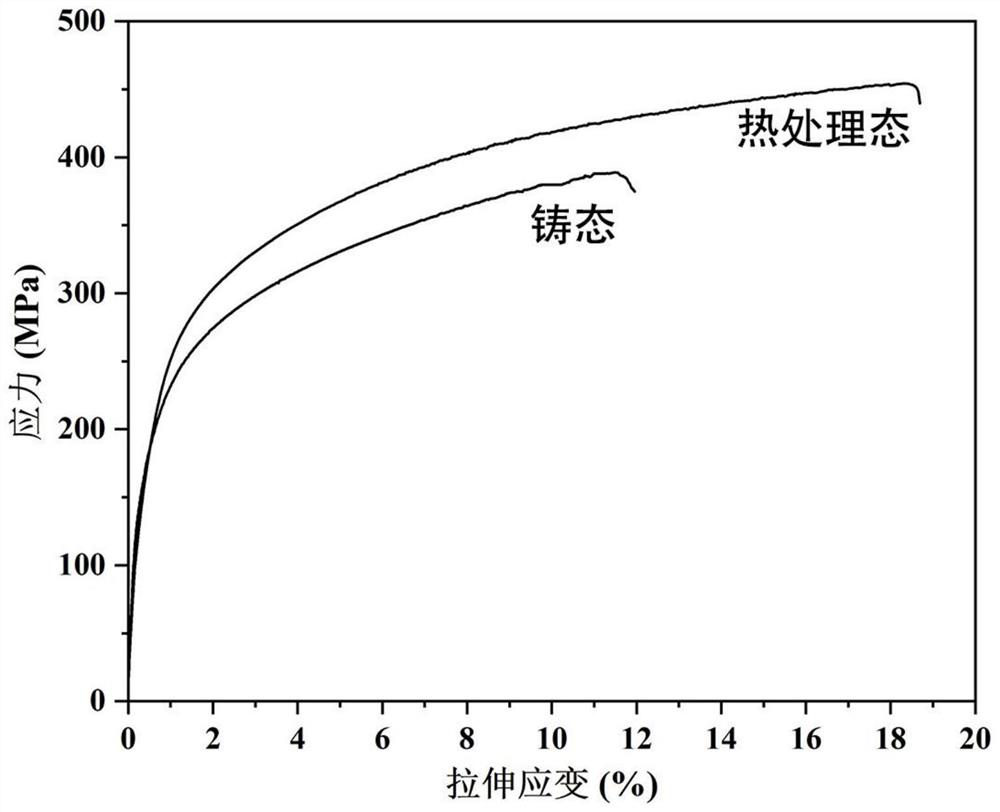

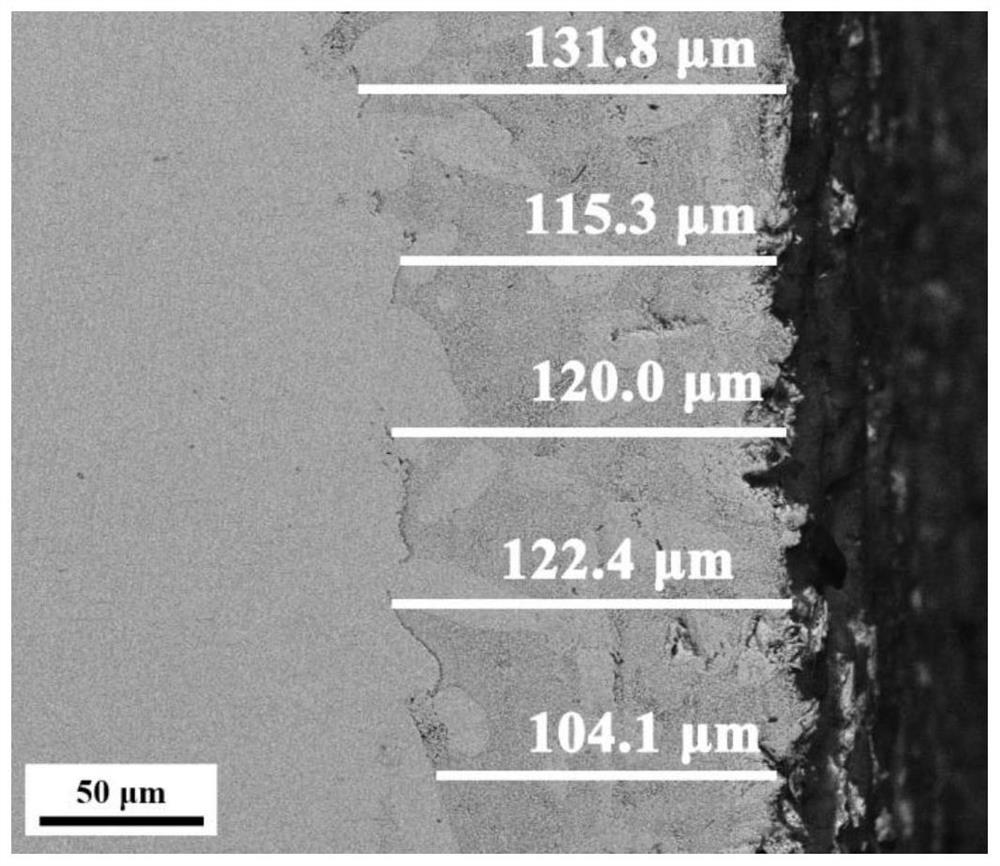

[0034]1) Composition design: Design the alloy composition and phase composition based on the virtual zinc equivalent rule. The mass percentages of Cu, Zn, Si and Al alloy elements are designed to be Cu 62.10%, Zn 36.555%, Si 0.85% and Al 0.39%, respectively. After calculation The virtual zinc equivalent of the alloy is 43.3%, and the expected structure of the alloy is α+β phase; in addition, the mass percentages of Ti, B and Re in the alloy are designed to be Ti 0.05%, B 0.005% and Re0.05 %;

[0035] 2) Preparation of materials or parts: first add pure silicon and electrolytic copper into the intermediate frequency induction furnace, and keep it at 1100°C for 20 minutes to completely melt it; then lower the furnace temperature to 800°C, then add pure aluminum and pure zinc, and hold it for 10 minutes; Raise the furnace temperature to 1100°C, add copper-titanium, aluminum-boron intermediate alloy and rare earth, keep it warm for 30 minutes, and then cast it into lead-free silic...

Embodiment 2

[0039] 1) Composition design: Design the alloy composition and phase composition based on the virtual zinc equivalent rule. The mass percentages of Cu, Zn, Si and Al alloy elements are designed to be Cu 59.155%, Zn 39.68%, Si 0.77% and Al 0.29%, respectively. After calculation The virtual zinc equivalent of the obtained alloy is 45.4%, and the expected structure of the alloy is α+β phase; in addition, the mass percentages of Ti, B and Re in the alloy are designed to be Ti 0.05%, B 0.005% and Re 0.05% respectively ;

[0040] 2) Preparation of materials or parts: first add pure silicon and electrolytic copper into the melting furnace of low-pressure casting equipment, keep it at 1150°C for 15 minutes to completely melt it; then lower the furnace temperature to 850°C, then add pure aluminum and pure zinc, keep warm 5min; raise the furnace temperature to 1150°C, add copper-titanium, aluminum-boron intermediate alloy and rare earth, keep warm for 10min, and then low pressure cast i...

Embodiment 3

[0044] 1) Composition design: Design the alloy composition and phase composition based on the virtual zinc equivalent rule. The mass percentages of Cu, Zn, Si and Al alloy elements are designed to be Cu 57.66%, Zn 40.484%, Si 1.26% and Al 0.50%, respectively. After calculation The virtual zinc equivalent of the alloy is 49.3%, and the expected structure of the alloy is β+γ phase; in addition, the mass percentages of Ti, B and Re in the alloy are designed to be Ti 0.03%, B 0.006% and Re 0.06% respectively ;

[0045] 2) Preparation of materials or parts: firstly add pure silicon and electrolytic copper into the intermediate frequency induction furnace, and keep it at 1130°C for 18 minutes to completely melt it; then lower the furnace temperature to 830°C, then add pure aluminum and pure zinc, and hold it for 8 minutes; Raise the furnace temperature to 1130°C, add copper-titanium, aluminum-boron intermediate alloy and rare earth, keep it warm for 20 minutes, and then cast it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com