Method and device for assisting in drilling tiny deep holes through electromagnetic-acoustic multi-field compounding

A magnetic field-assisted, drilling technology, applied in boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve the problem of speeding up the grinding and damage of micro-drilling tools, long chip removal path, and increased drill force. and other problems, to achieve the effect of improving bending deformation and irregular swinging phenomenon, improving dimensional accuracy and shape and position accuracy, reducing cutting force and tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

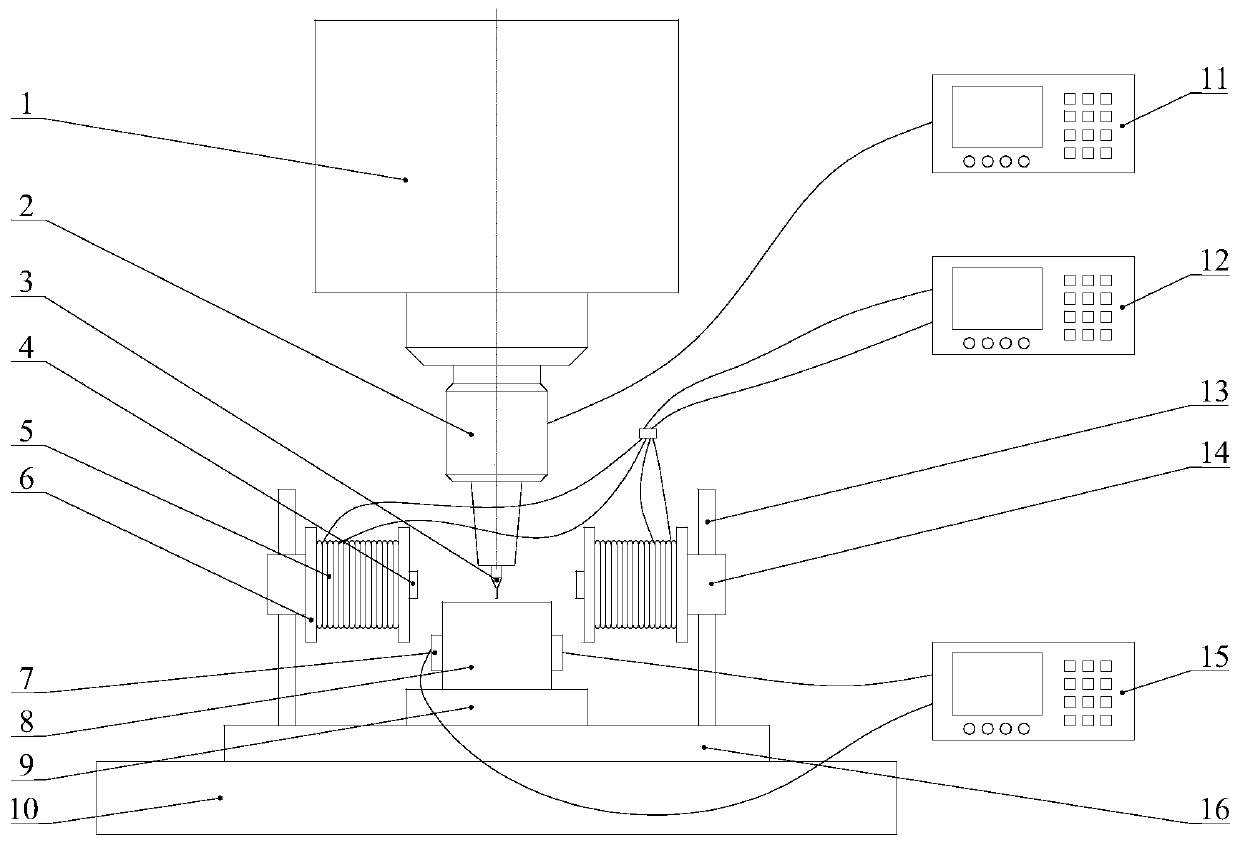

[0042] A method and device for drilling tiny deep holes with the aid of electromagnetic acoustic multi-field compounding are used to process tiny deep holes with a diameter of 0.5mm and a hole depth of 5mm on a mold steel material. The drilling tool 3 is a cemented carbide drill bit, and the tool-workpiece cutting area is placed in a pulsed magnetic field between two magnetic poles 4 during processing. The vibration frequency of the ultrasonic vibration tool holder 2 is set to 25kHz, and the amplitude is set to 6 μm; the voltage of the pulse electric field is set to 2V, the frequency is set to 300Hz, and the pulse duty cycle is set to 50%; the pulse magnetic field intensity is set to 2.5T, the frequency is set to 20Hz. On the machine tool, the spindle speed is set to 20000r / min, the drilling feed rate is 10mm / min, the pecking drilling method is adopted, and the pecking drilling step depth is 50μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com