Double-surface chip breaking arc-shaped edge anti-attrition turning tool blade under high-temperature cooling

A technology of arc-shaped blades and blades, which is applied in the direction of lathe tools, turning equipment, tool holder accessories, etc., can solve the problems of difficult chip breaking, shortened service life, high cutting temperature, etc., to reduce tool wear and prevent winding , The effect of reducing the cutting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

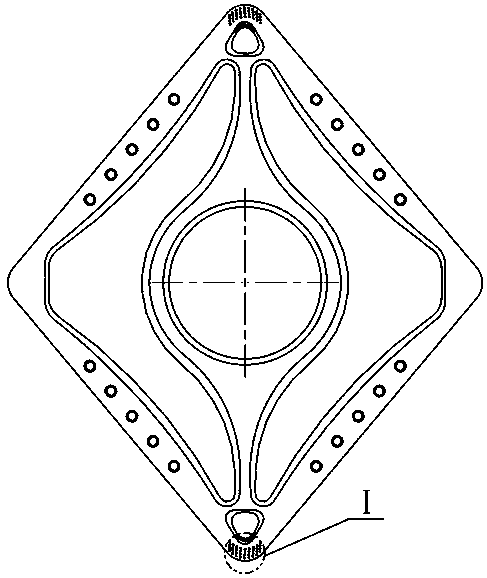

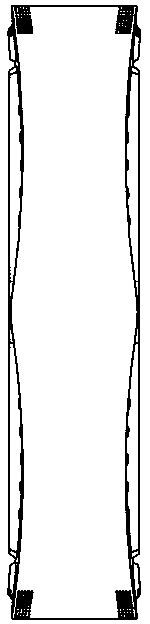

[0020] Specific implementation mode one: combine Figure 1-Figure 6 Explain, a double-sided chip-breaking arc-edge wear-reducing blade under high-pressure cooling in this embodiment, the shape of the blade is a rhombus with an angle of 80°, and it adopts a design that can be used on both sides, and the position running through the geometric center of the blade is a fastening threaded hole (12), there are two hand-shaped tiger mouth bosses (1) near the fastening threaded hole (12) in the middle area of the blade, and a high-pressure volume groove (9) around the fastening threaded hole (12) between the two, There is a high-pressure diversion groove (8) between the ends of the two-handed tiger mouth boss (1), and an arc-shaped edge (2) is provided around the blade, and an arc-shaped edge (2) is provided on the arc-shaped rake face (11) along the arc-shaped edge (2). Button-shaped projections Button-shaped projections (10), every two arc-shaped blades (2) at the intersection of ...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 , figure 2 and image 3 Explain that the arc-shaped edge (2) described in this embodiment has a radius of curvature of 60mm, so that the edge angle of each point on the cutting edge is different. During cutting, the tool has a certain edge angle due to the effect of the curved edge, and the existence of the edge angle changes. The direction of chip flow is defined, so that it is discharged toward the direction of the chip breaker, away from the machined surface of the workpiece, avoiding the chip from scratching the workpiece, improving the quality of the machined surface, and ensuring the accuracy of the machined surface.

specific Embodiment approach 3

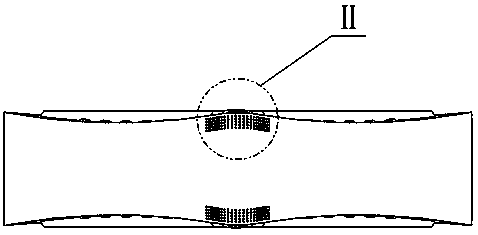

[0022] Specific implementation mode three: combination figure 1 and Figure 4 Explain that the circular-arc tool tip (7) and the arc-shaped edge (2) in this embodiment are the direct contact area between the blade and the chips, and are also areas of severe wear. The circular pit lattice microtexture (5), the pit diameter is 20 μm, the depth dimension conforms to the arithmetic sequence whose first term is 20 μm, and the tolerance is 10 μm; this kind of circular pit lattice microtexture (5) The distribution method has a certain absorption and dispersion effect on the stress, which can improve the stress distribution of the tool, make the overall stress distribution of the tool relatively uniform, and have no obvious stress concentration, and play a role in protecting the arc tool tip (7), thereby prolonging the service life of the tool ; At the same time, when the frontal friction and bonding between the cutter face and the chip are reduced, the chip will be curled, which wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com