Longitudinally torsional compound ultrasonic vibration drilling device

A composite ultrasonic and composite vibration technology, which is applied in the direction of vibrating fluid, boring/drilling, drilling/drilling equipment, etc., to achieve obvious effects, simple structure, and reduce drilling force and drilling heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

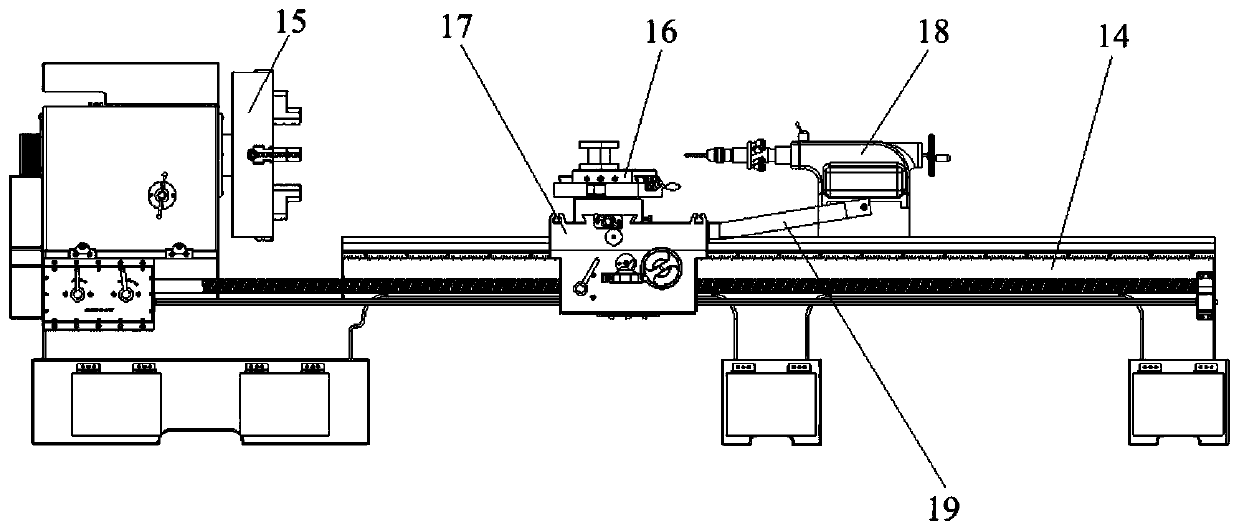

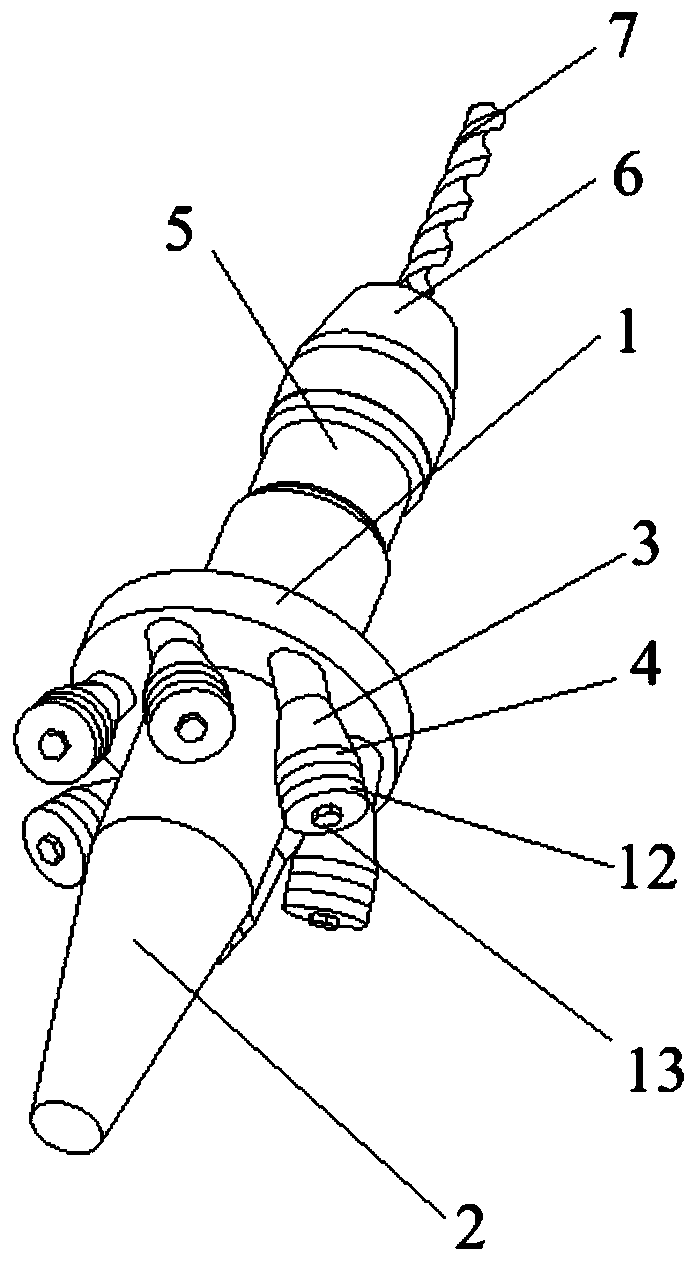

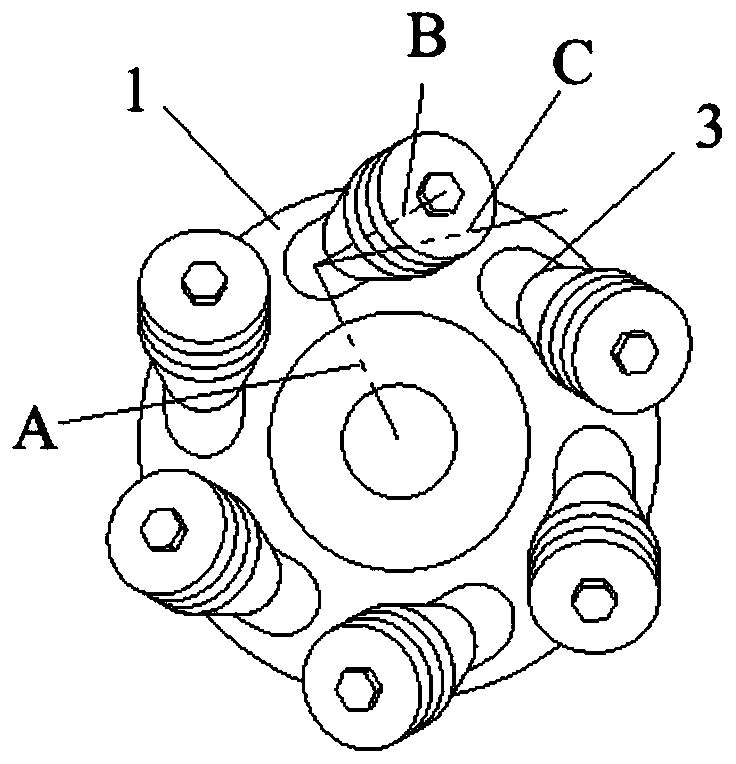

[0020] The embodiment of the present invention: such as Figure 1-Figure 4 As shown, a longitudinal torsion composite ultrasonic vibration drilling device includes turning equipment. The turning equipment is equipped with a longitudinal torsion composite vibration mechanism. The turning equipment can use the equipment in the prior art. The longitudinal torsion composite vibration mechanism includes a flange. 1. Morse cone 2, horn 3 and piezoelectric ceramic sheet 4. Flange 1 is arranged on Morse cone 2. The two are coaxially arranged and rigidly connected. The shank end of Morse cone 2 is elastic The chuck 5, the connection between the two is preferably threaded, the elastic chuck 5 is equipped with a lock nut 6, and the twist drill 7 is plug-connected to the elastic chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com