Variable-feed cutting method for circular groove machining

A cutting method and annular groove technology, which are applied in the field of mechanical processing, can solve the problems of poor chip breaking effect, etc., and achieve the effects of improving tool life and processing efficiency, good curling effect, and stable roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

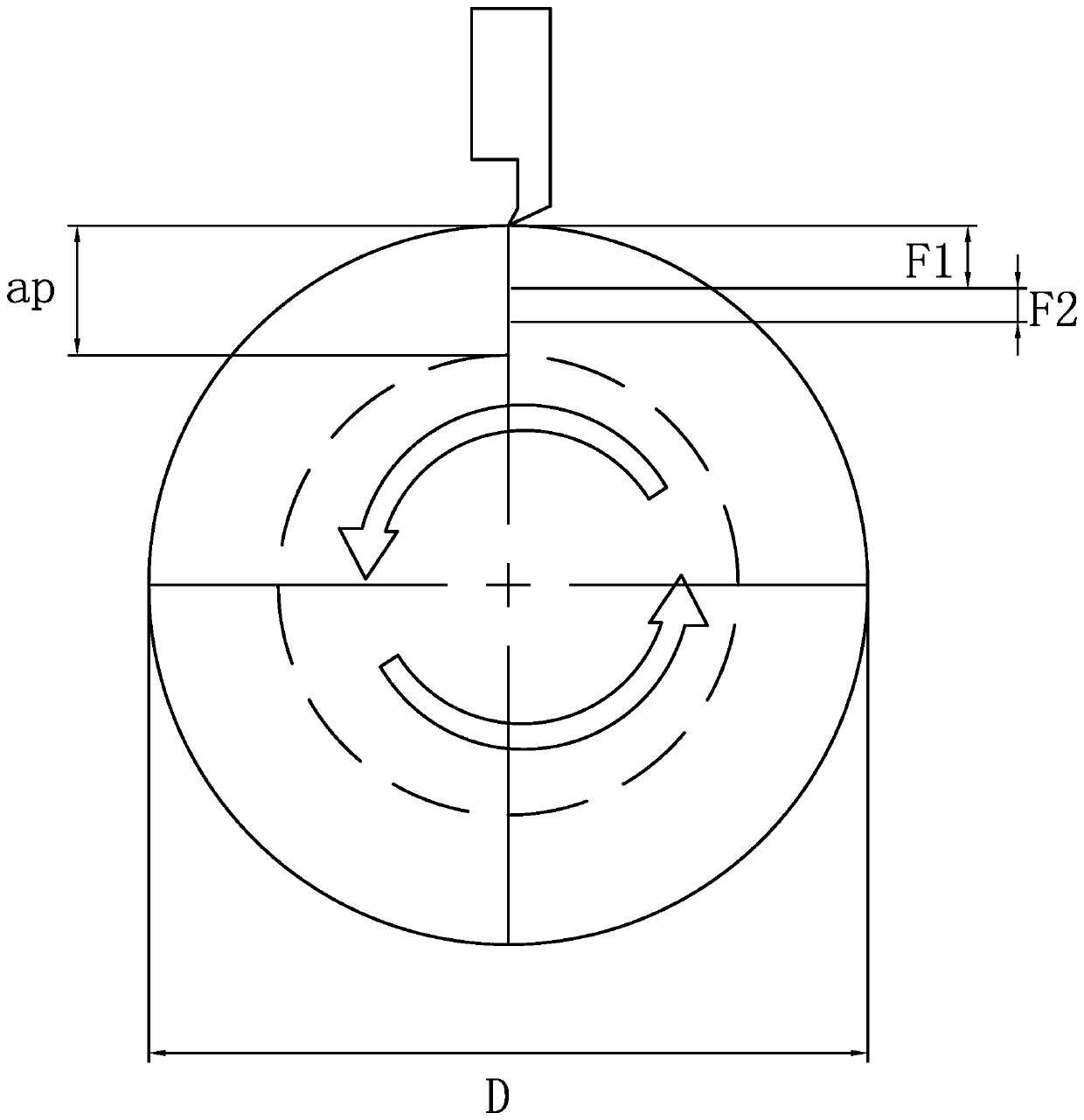

[0023] Specifically, in this embodiment, this method is applied to a CNC lathe. The CNC lathe performs grooving on the workpiece by executing multiple variable feed cycles in the same cutting circle. Each variable feed cycle includes normal feed Quantity F1 and variable feed F2, before processing, set the diameter of the cutting circle D, set the expansion rate of the material β, set the depth of cut ap per revolution of the spindle, and set the required length of chips cut out by a variable feed cycle L, set the normal feed amount F1, and then calculate the F2=(L*ap-β*F1*лD) / (лD*β) through the formula to set, where as figure 1 As shown, F2, F1, and ap need to satisfy the following relationship: F2<F1<ap, F1+F2<ap, and then perform the following steps:

[0024] Step 1, the workpiece is cut with the feed rate of F1, and the number of rotations of the spindle at this time is F1 / ap;

[0025] Step 2: After step 1 is completed, the workpiece is cut with the feed rate of F2. At thi...

Embodiment 2

[0030] The technical solution of this embodiment is basically the same as the technical solution of the first embodiment, the difference is that in this embodiment, the variable feed rate is not calculated by a formula, but an empirical value obtained by an experimental test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com