Fracture-toothed rough milling cutter

A rough milling cutter and tooth breaking technology, applied in milling cutters, milling cutting inserts, milling machine equipment, etc., can solve the problems of affecting tool life, unbalanced force, poor chip breaking, etc. The effect of increasing overall strength and reducing the possibility of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention discloses a tooth-broken rough milling cutter, which is used for high-speed, superhard precision cutters in advanced mechanical equipment and devices in automatic machinery and equipment, specifically a round tooth-broken rough machining end mill, which can be applied to Rough machining of scroll housings.

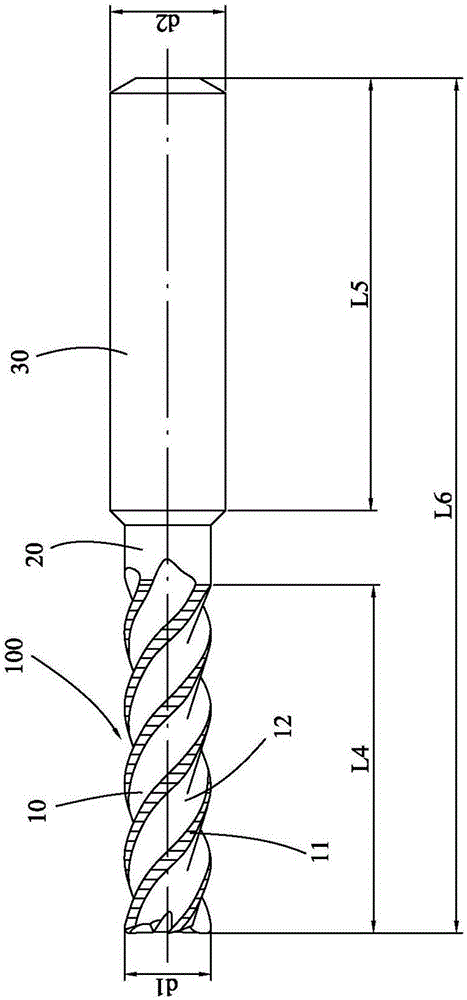

[0028] Such as figure 1 As shown, the broken tooth rough milling cutter 100 includes: a head 10, a transition portion 20 connected to the head 10, and a shank 30 connected to the transition portion 20, wherein one end of the transition portion 20 is connected to the transition portion 20 The handle 30 is connected, and the other end of the transition part 20 is connected with the head 10 .

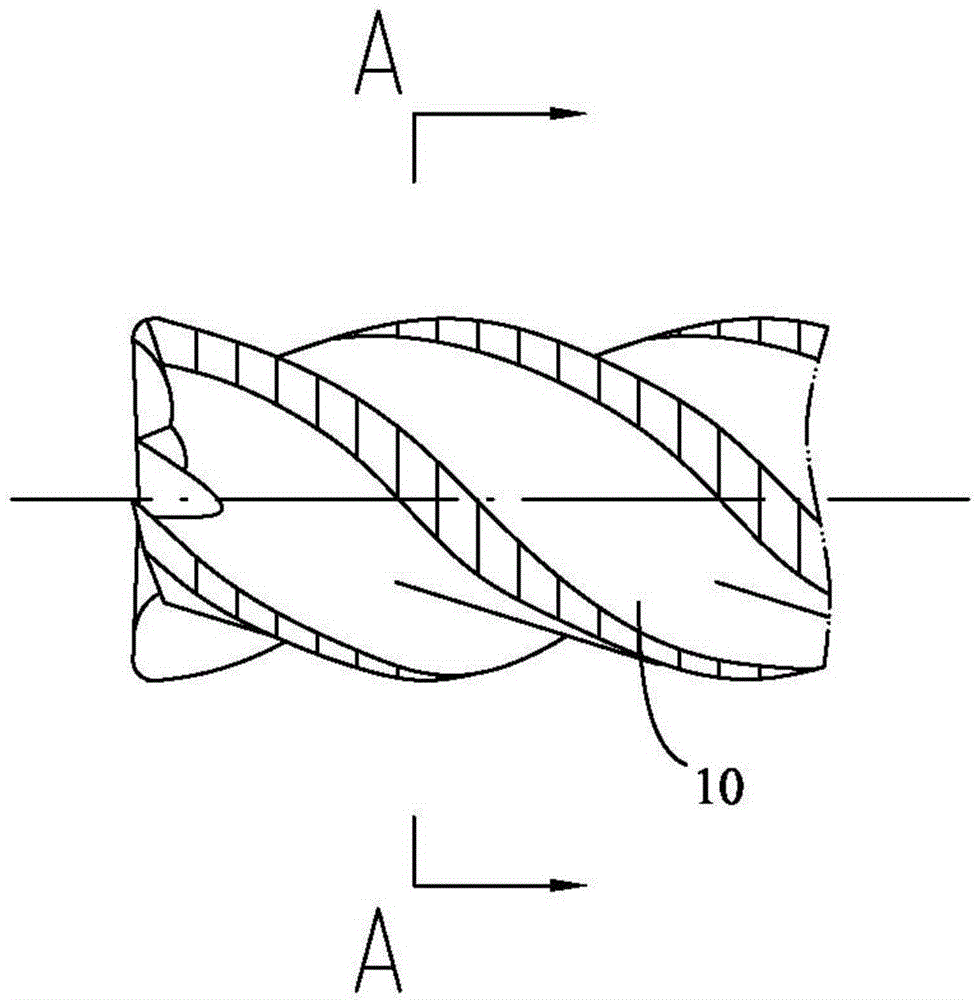

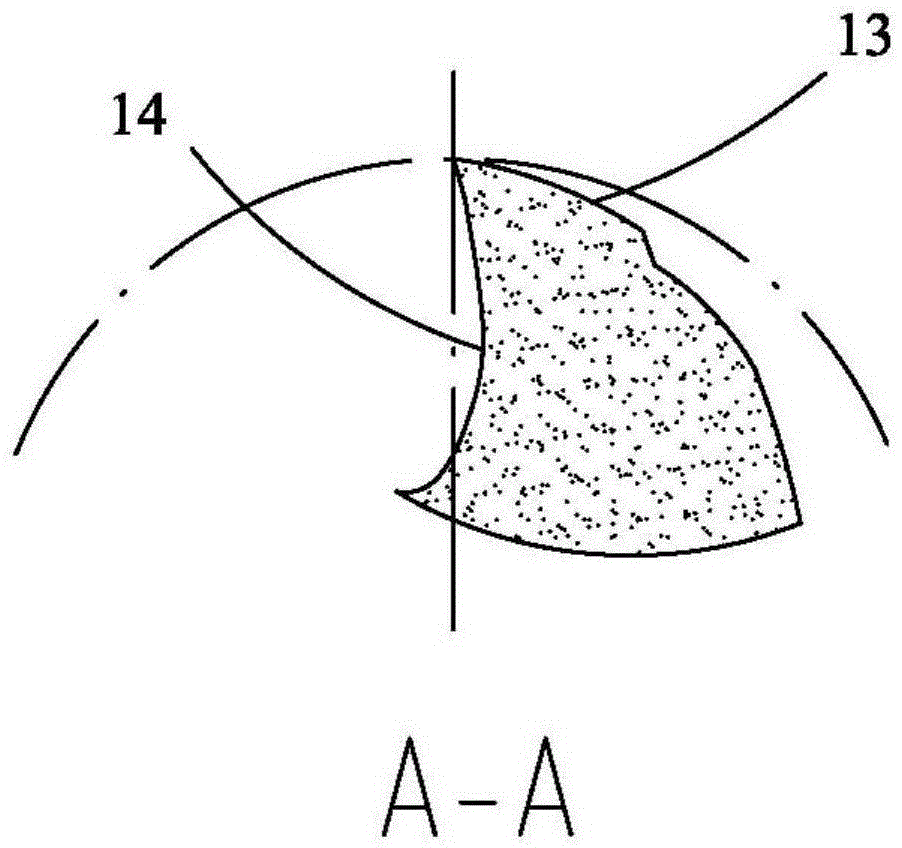

[0029] The head 10 is provided with three cutting edges 11 at equal intervals, and chip removal grooves 12 are arranged between adjacent cutting edges 11 .

[0030] The diameter of the head 10 is d1, and the length of the head 10 is L4, which is generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com