Polycrystalline diamond compact for plastic stratum

A polycrystalline diamond and composite sheet technology, which is applied in drilling equipment, earth-moving drilling, drill bits, etc., can solve the problems of increasing the additional wear of the composite sheet, insufficient chip breaking ability, and difficulty in drilling, so as to enhance the chip breaking ability and reduce the Adverse effects, longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

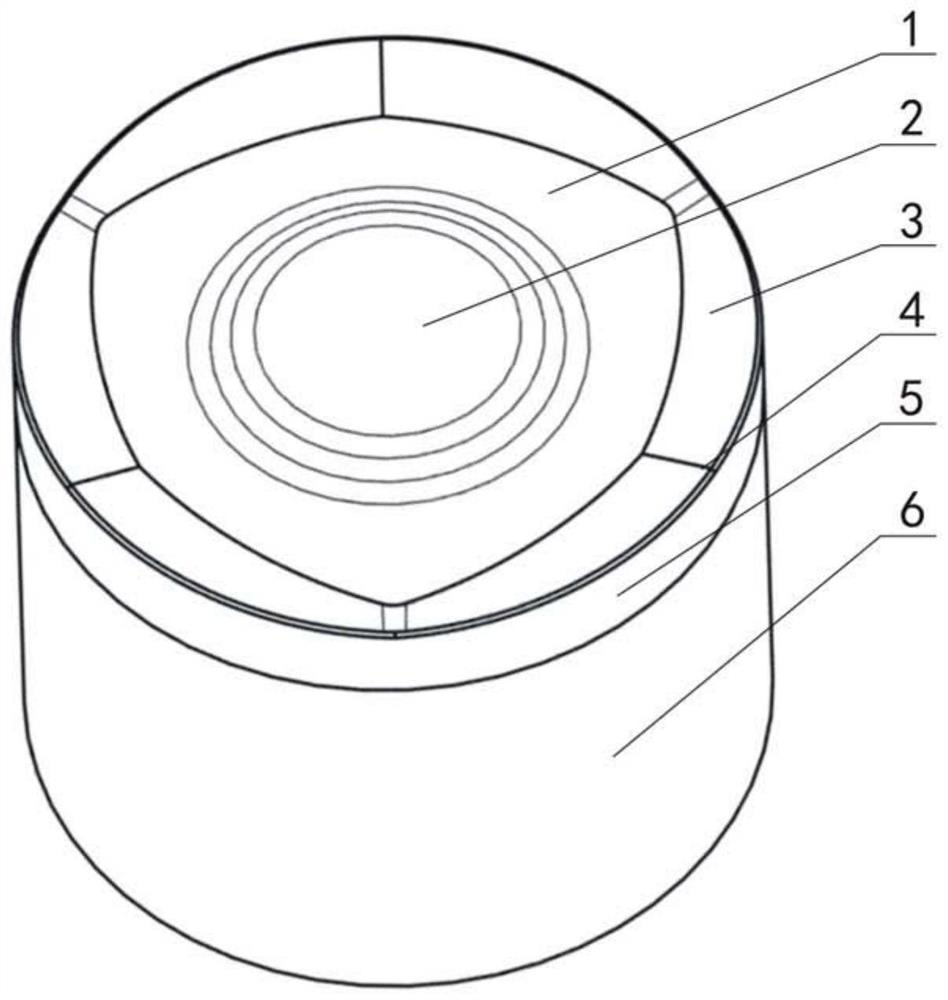

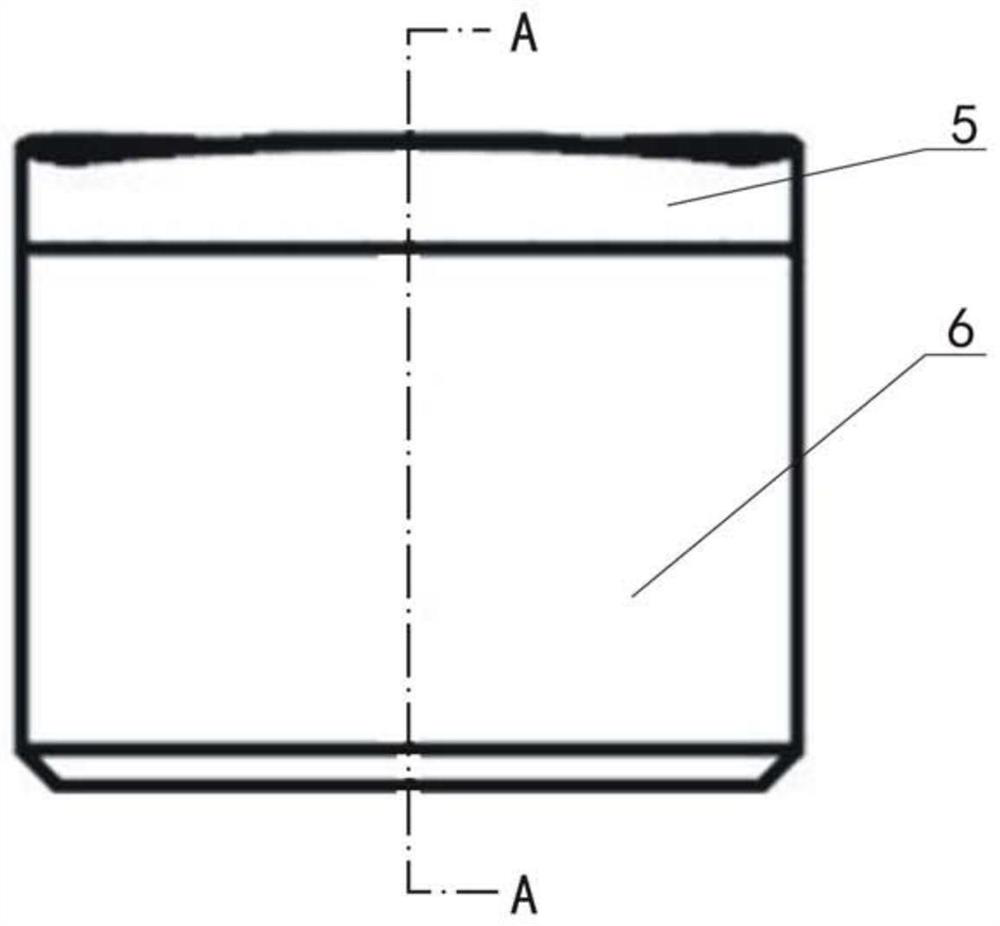

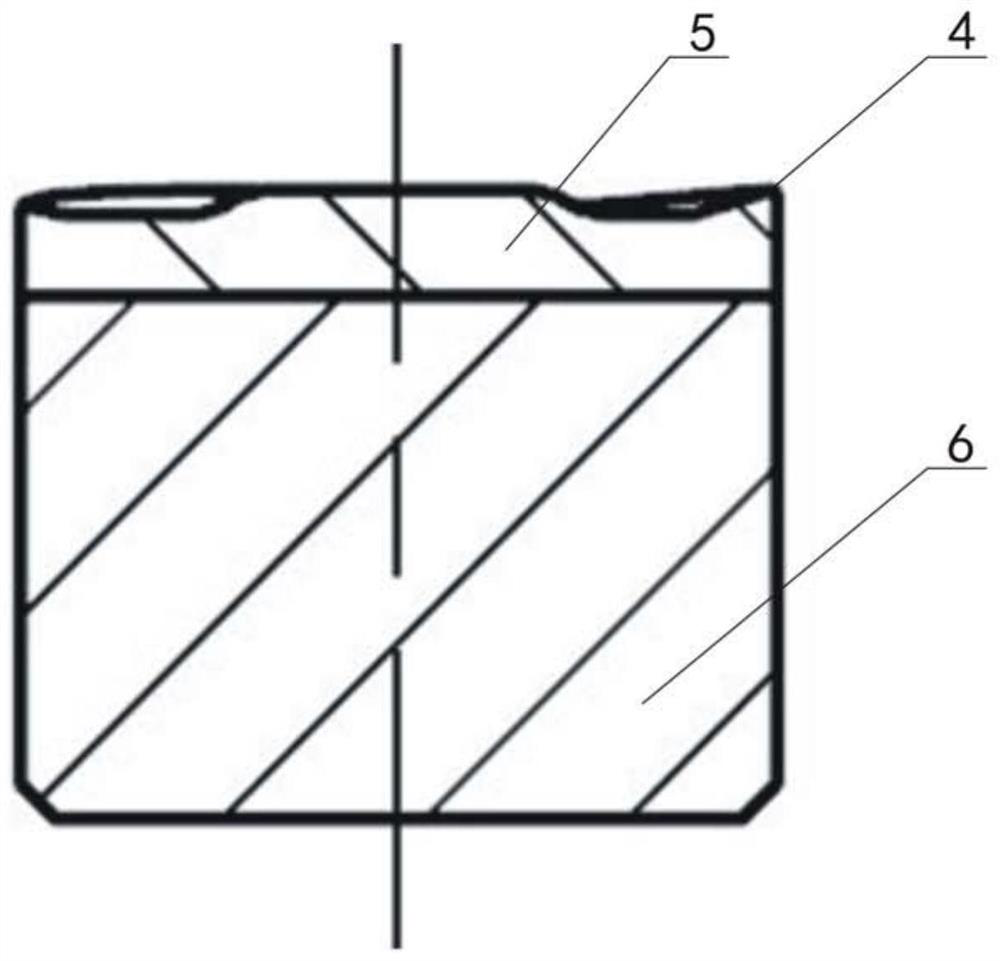

[0029] Such as Figure 1-Figure 4 As shown, the polycrystalline diamond composite sheet for plastic formations of the present invention includes a polycrystalline diamond layer 5 and a cemented carbide substrate 6, the rear end of the polycrystalline diamond layer 5 is connected to the front end of the cemented carbide substrate 6, and the polycrystalline diamond layer The middle part of the front end face of 5 is provided with a concave inner cavity 1, and the middle part of the inner cavity 1 is provided with a protruding boss 2, and the top of the boss 2 is not higher than the top of the cavity wall of the inner cavity 1, and the ring shape of the inner cavity 1 The annular wall surface of the cavity wall is formed by connecting multiple (six in the figure) block-shaped wall surfaces 3 that are flat or arc-shaped. The angle between two adjacent block-shaped wall surfaces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com