Multi-element copper alloy up-drawing furnace and drawing casting method

A copper alloy, multi-component technology, applied in the field of multi-component copper alloy upper induction furnace and casting, can solve the problems of internal stress, increased probability of fragmentation, and shortened service life of upper lead molds, so as to prolong the service life and slow down graphite burning Damage, reduce the effect of the chance of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

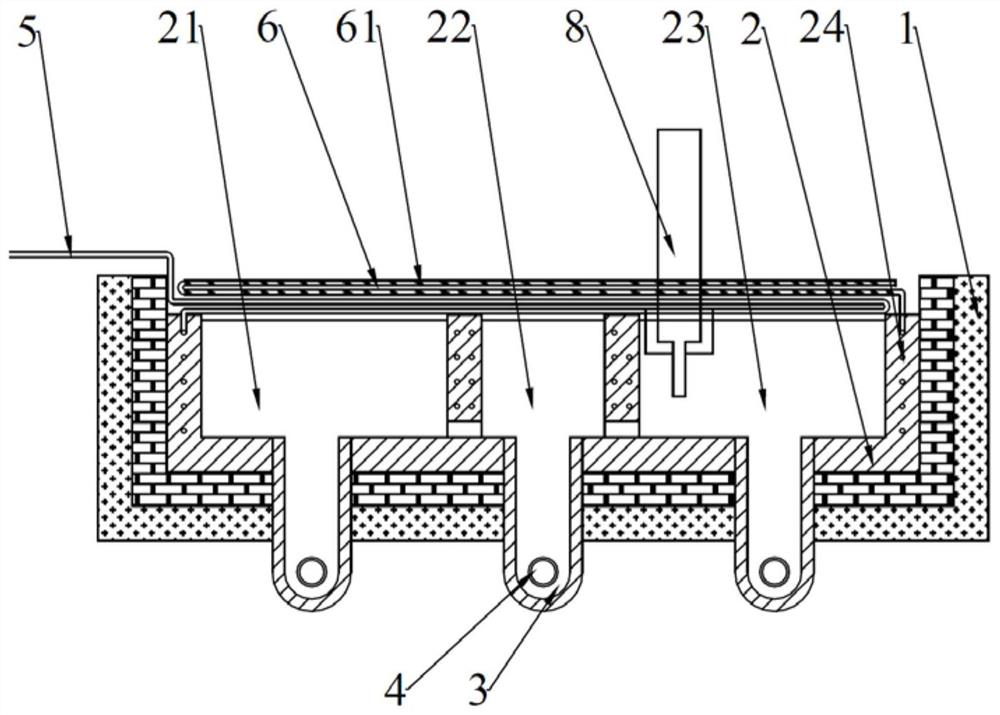

Embodiment 1

[0059] The graphite molten pool 2 size of embodiment 1, embodiment 4, comparative example 1, comparative example 2 is that molten pool inner cavity is long 5.397m, wide 0.4m, high 0.5m; Melted pool side wall thickness 150mm, bottom wall thickness 150mm; The inner diameter of the trench is 580mm, and the inner diameter of the inert gas channel 24 in Example 1 is 8mm; the volume ratio of the melting chamber 21, the transition chamber 22 and the upper induction chamber 23 in the side-by-side direction is 2.179:1:2.218. The graphite molten pool 2 size of embodiment 2 and embodiment 3 is the same as embodiment 1.

Embodiment 2

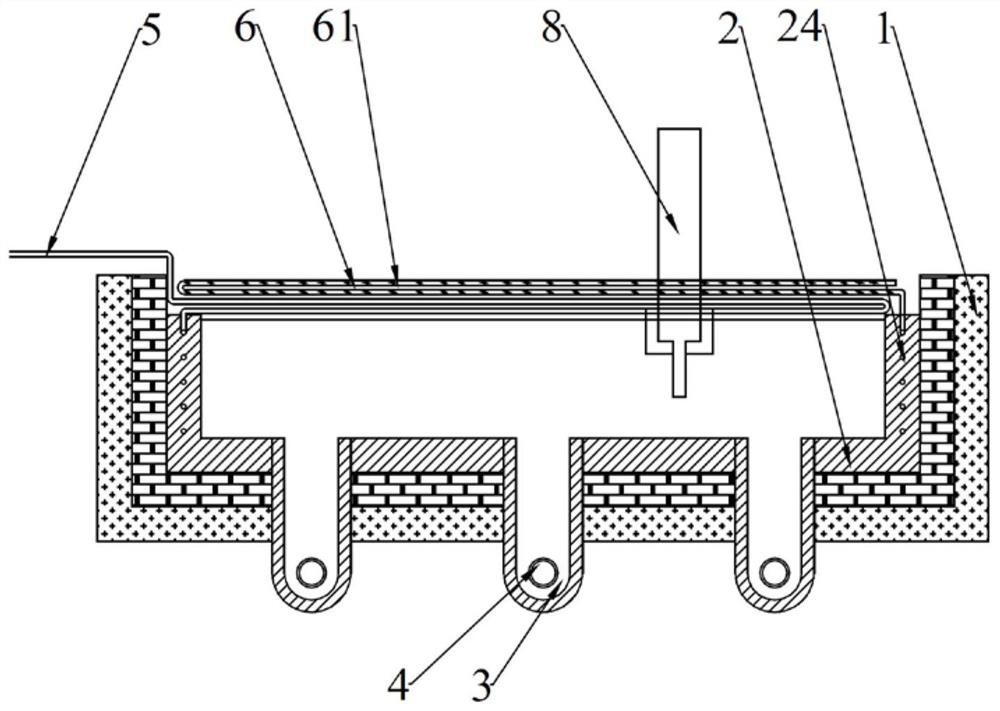

[0061] Such as figure 2 As shown, embodiment 2 is based on embodiment 1, the difference is that no separator 3 is provided in the graphite molten pool 2, and the inert gas passages 24 are spirally wound around the side walls of the graphite molten pool.

Embodiment 3

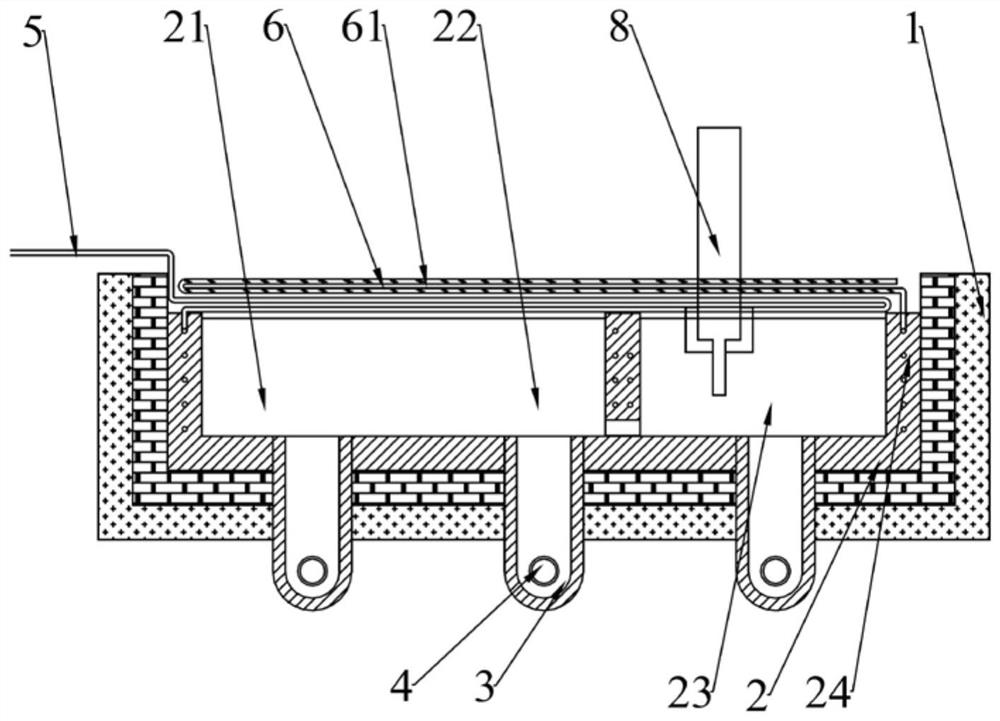

[0063] Such as image 3 As shown, embodiment 3 is based on embodiment 1, the difference is that graphite molten pool 2 is provided with a partition 3, and the position of partition 3 is the same as that of partition 3 between transition chamber 22 and upper introduction chamber 23 in embodiment 1 The clapboard 3 separates the inner cavity of the graphite melting pool 2 into a melting cavity 21 and an upper lead cavity 23, two inner circulation melting grooves 3 are arranged in the melting cavity 21, and one inner circulation melting groove is arranged in the upper leading cavity 3. The inert gas channel 24 is arranged in the side wall and the partition of the graphite melting pool, and is arranged spirally in the side wall of the melting chamber 21 and the upper induction chamber 23 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com