High-speed steel tool forging technology

A technology of high-speed steel and knives, which is applied in the field of forging knives, can solve the problems of knives prone to chipping, reduce the possibility of chipping, improve shape, and improve the effect of microstructure and mechanical properties after forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The embodiment of the present application discloses a high-speed steel cutting tool forging process.

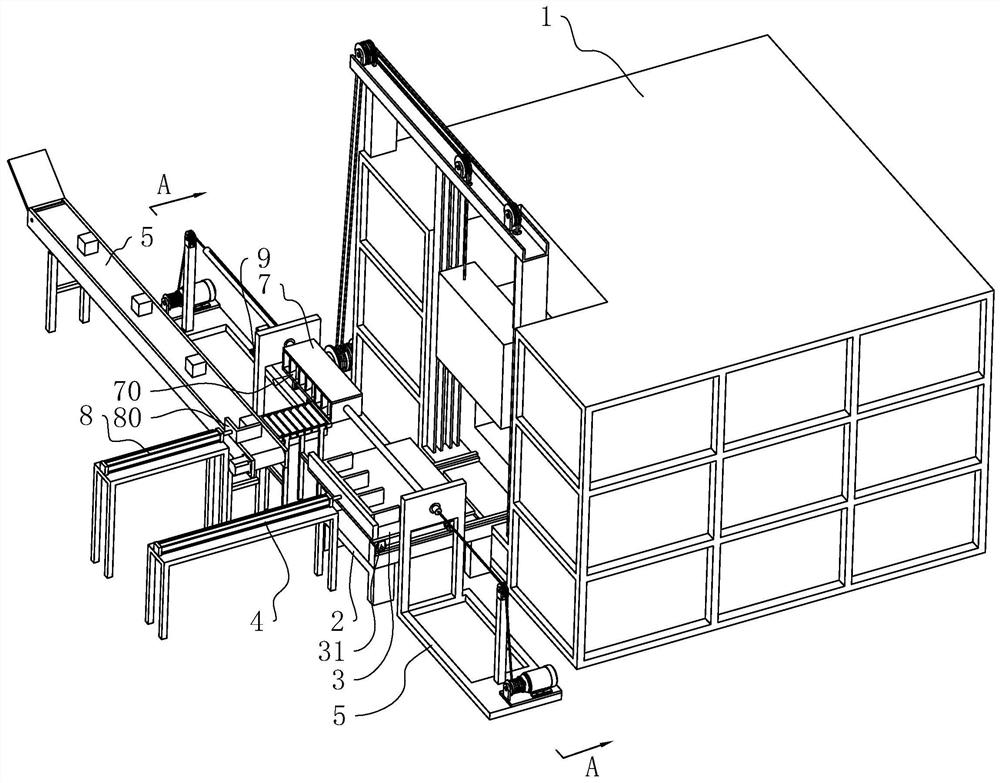

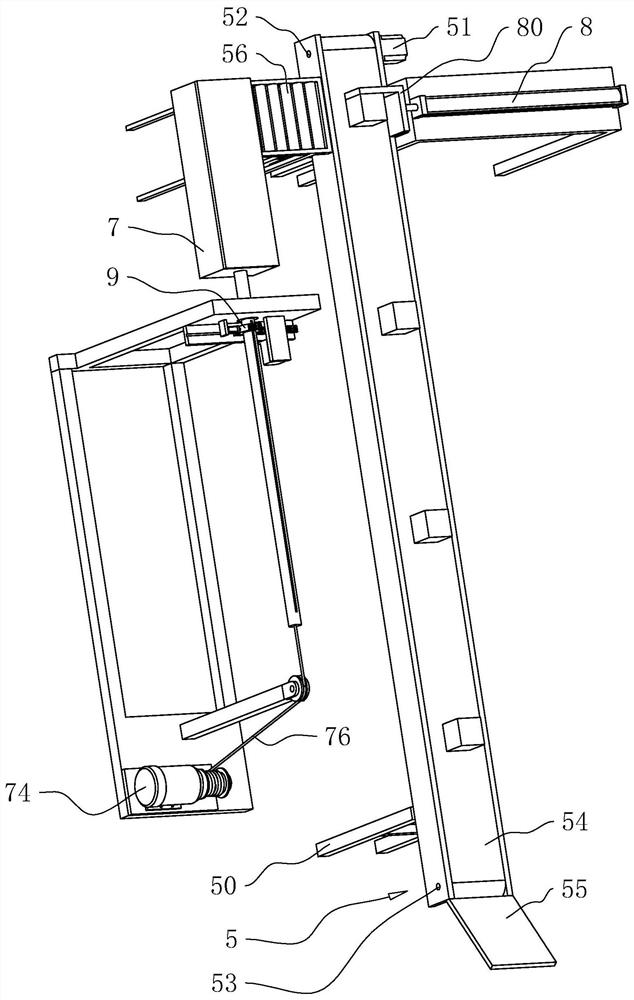

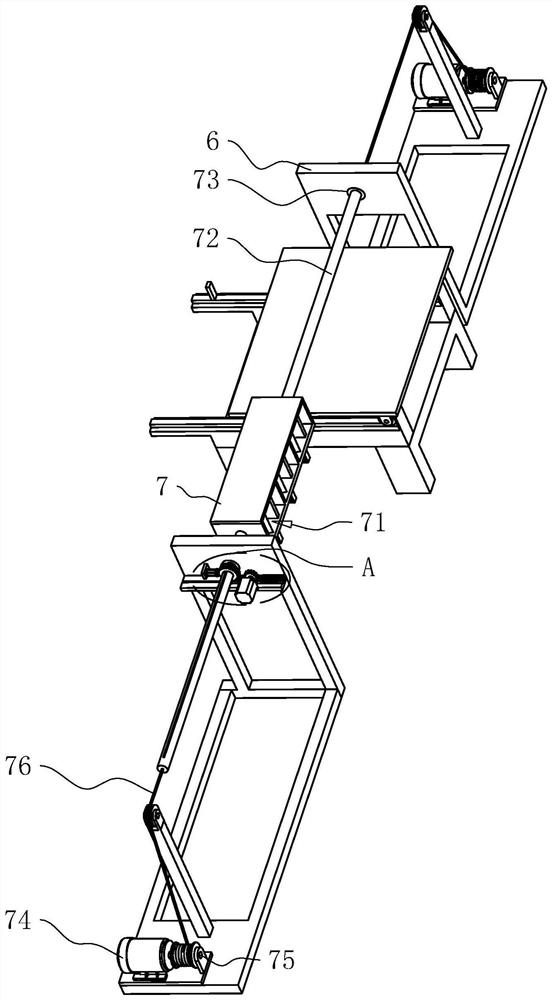

[0057] refer to figure 1 , a high-speed steel cutting tool forging process, comprising the following steps:

[0058] S1, prepare the ingredients, use the band saw to cut the high-speed steel ingot into pieces to form a billet, the size of the billet is 20cm*20cm*15cm;

[0059] S2. Put the billet into the desktop heating furnace 1 for heating, the heating temperature is 500°C, then increase the temperature, control the heating rate at less than 80°C per hour, and then keep warm at 850°C, so that the plasticity of the billet can be improved and the billet can be reduced. Anti-deformation ability, the billet is easy to form, and can also obtain good microstructure and mechanical properties after forging.

[0060] S3. Heat the preheated billet to a temperature of 1130-1180°C, put it into a forging mold for forging, and form the preliminary shape of the tool. The initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com