Manufacturing method of fin field-effect transistor

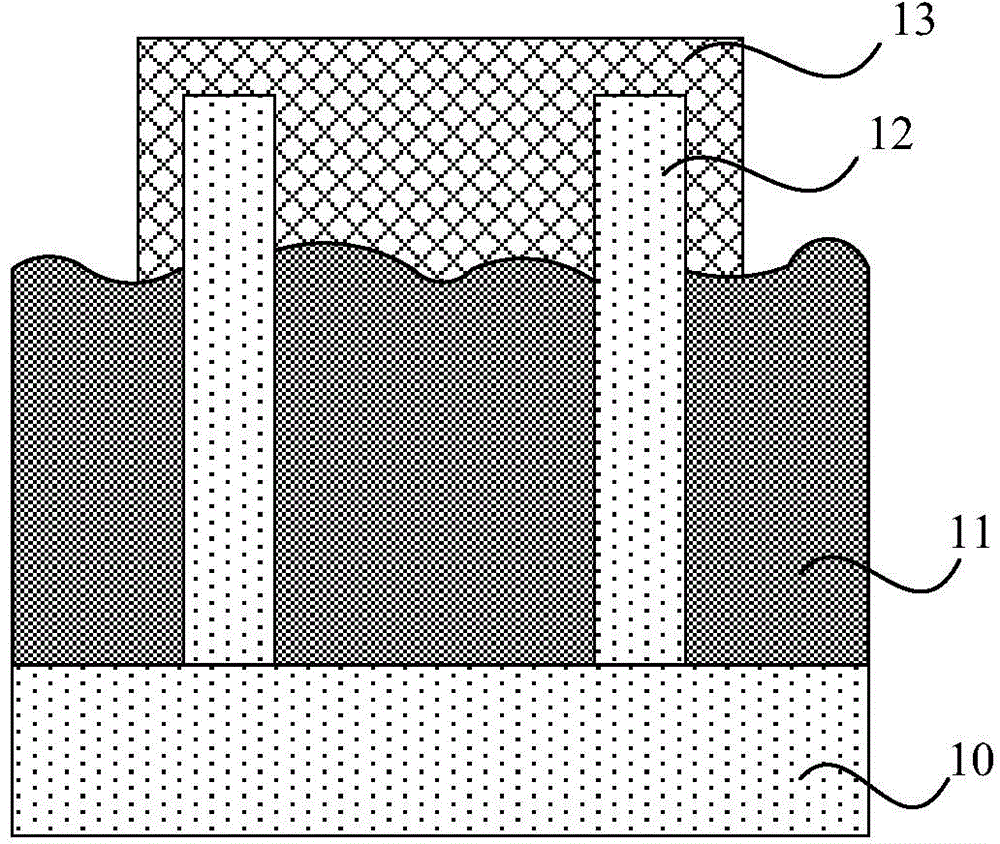

A technology of fin field effect and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of reducing device stability, uneven surface morphology of shallow trench isolation 11, and oxide surface morphology. Inconsistent appearance and other problems, to achieve the effect of reducing aspect ratio, improving flatness, and improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose and features of the present invention more obvious and easy to understand, the following will further describe the specific embodiments of the present invention in conjunction with the accompanying drawings. However, the present invention can be realized in different forms, and should not be considered as being limited to the described embodiments .

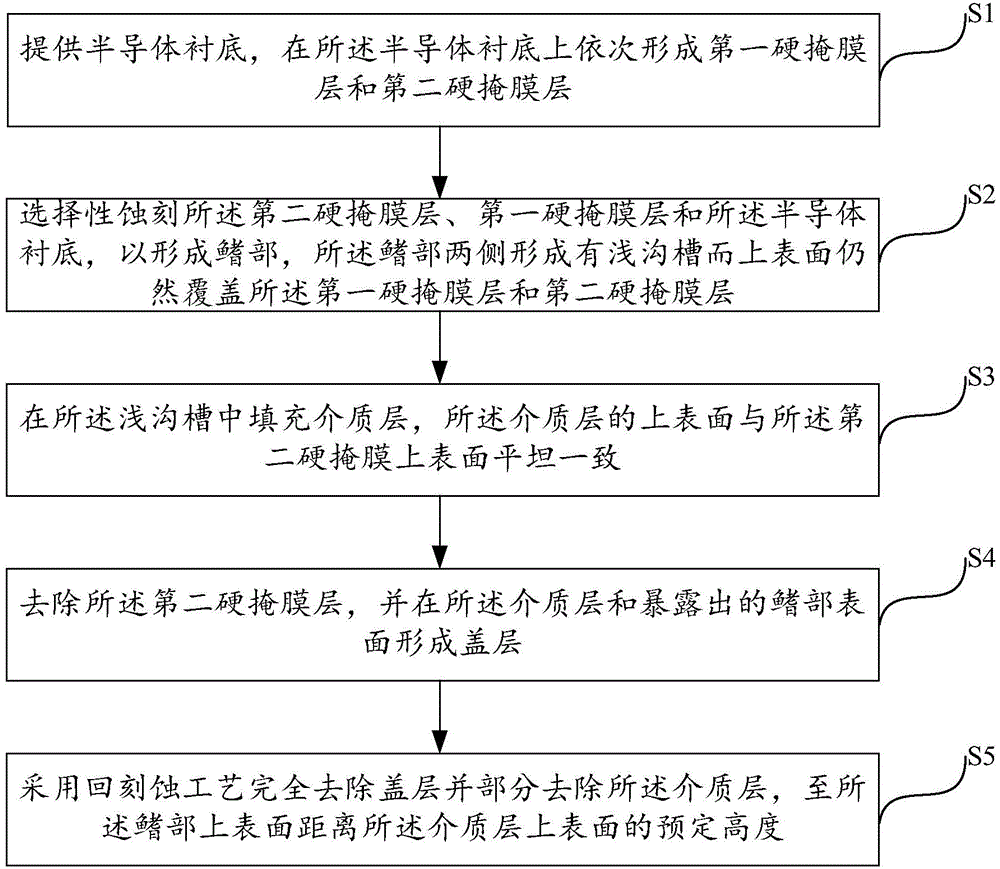

[0029] Please refer to figure 2 , an embodiment of the present invention provides a method for manufacturing a fin field effect transistor, comprising the following steps:

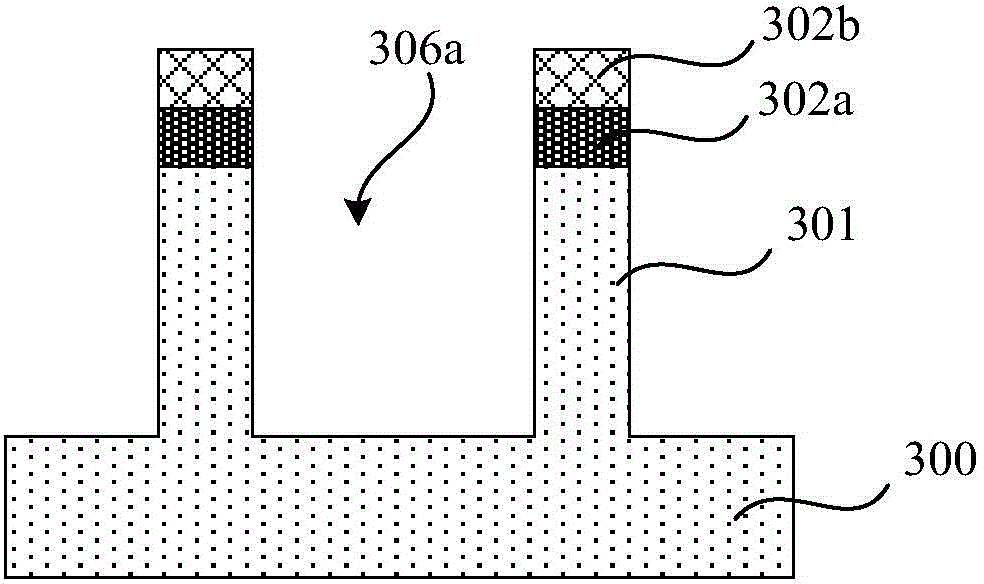

[0030] S1, providing a semiconductor substrate, on which a first hard mask layer and a second hard mask layer are sequentially formed;

[0031] S2, selectively etching the second hard mask layer, the first hard mask layer and the semiconductor substrate to form fins, shallow trenches are formed on both sides of the fins and the upper surface still covers the The first hard mask layer and the second hard mask layer;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com