Liquid-solid fluidization shaping method for low-cost titanium powder for 3D printing

A 3D printing, low-cost technology, which is applied in the field of liquid-solid fluidization shaping of low-cost titanium powder for 3D printing, can solve the problems of complex process, high cost, and high requirements for spherical titanium powder production equipment, and achieve simple equipment and low cost. The effect of low cost, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

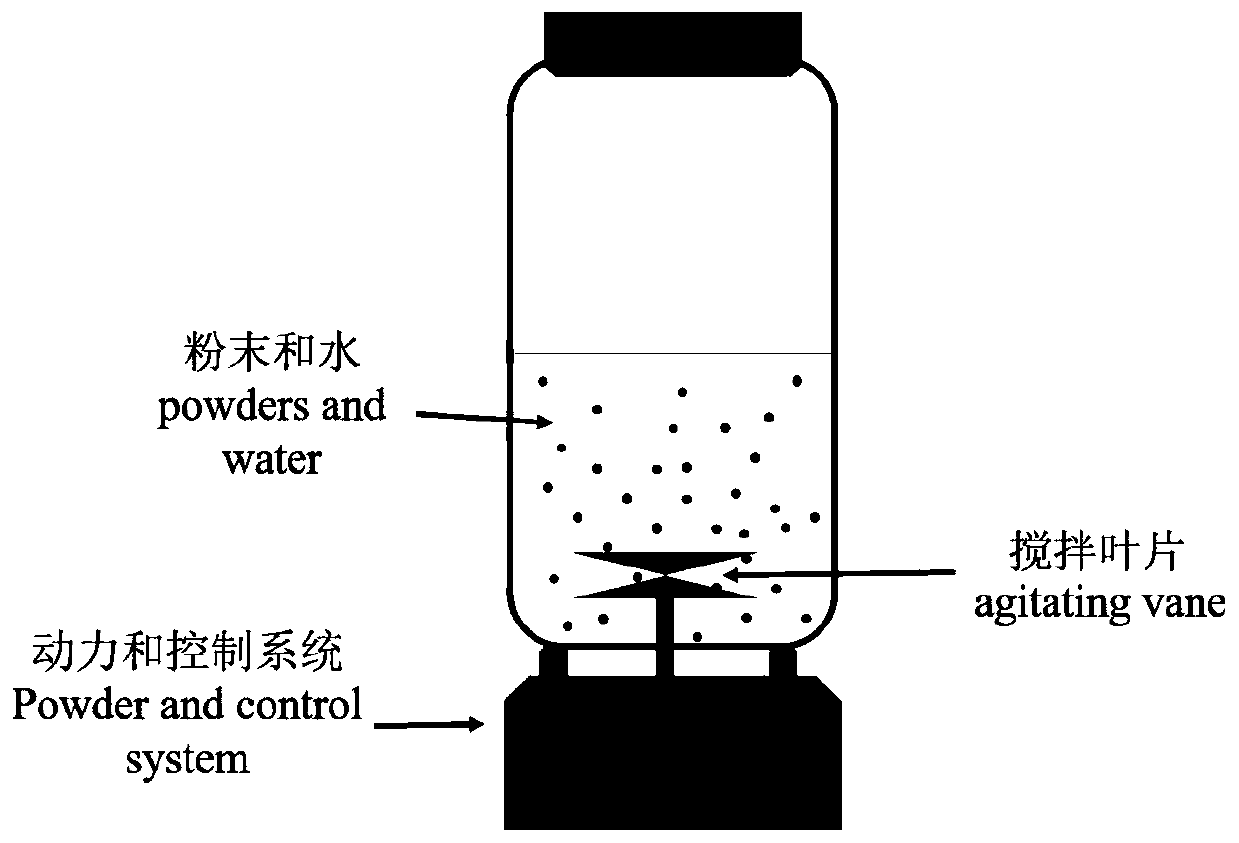

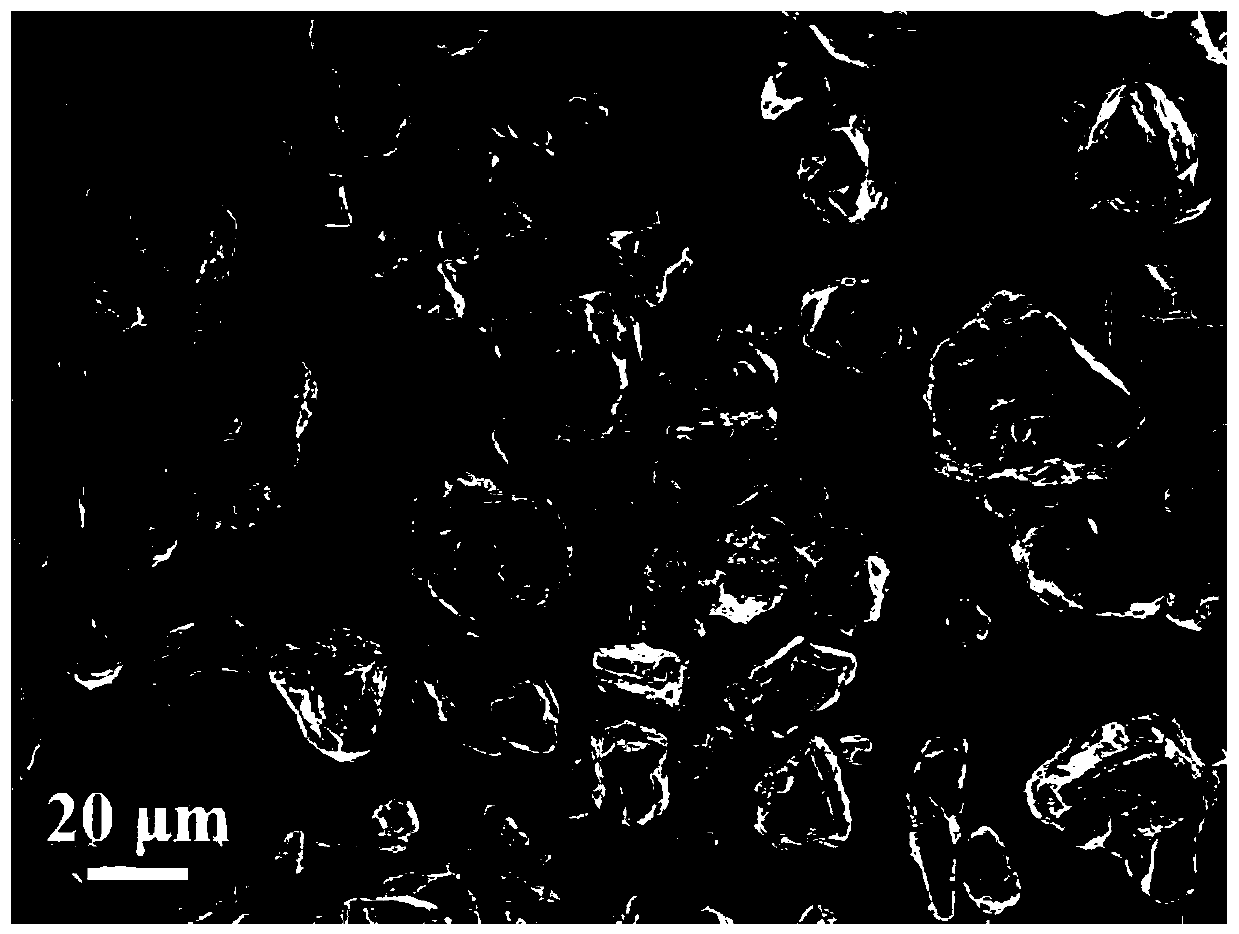

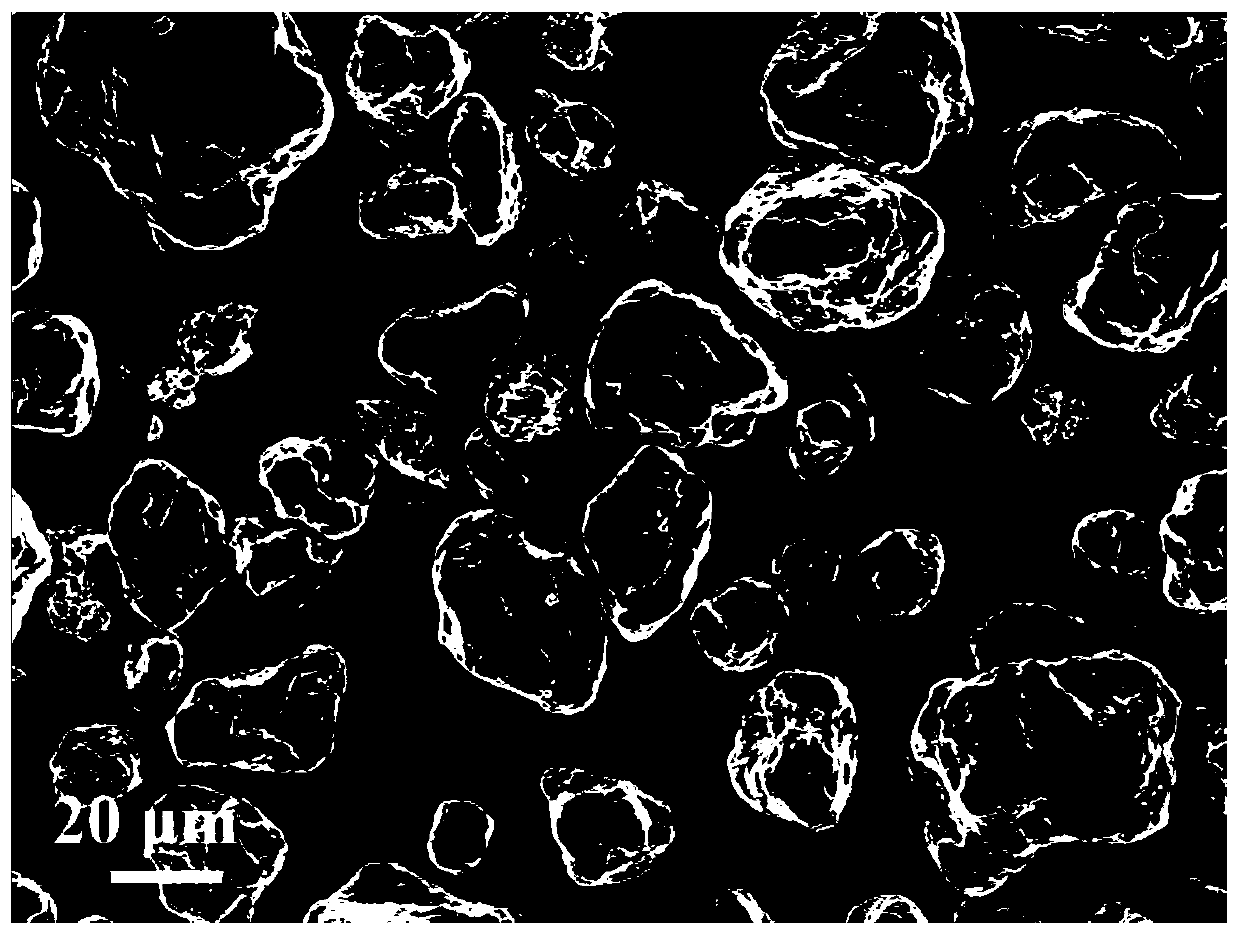

[0021] Weigh 300g irregular hydrogenated dehydrogenation titanium powder (microscopic appearance such as figure 2 Shown), added to the stirring container, and then added 200ml of deionized water and titanium powder to mix evenly, in order to prevent the titanium powder from being oxidized in contact with air. Set the rotation speed to 30,000 rpm, liquid-solid fluidization shaping for 1.5min, and let it cool naturally for 10min after shutting down, then add the titanium powder mixture into the Buchner funnel to filter, and then take the filtered titanium powder in a vacuum drying oven at 70°C Dry for 5 hours and take the powder for vacuum packaging. The titanium powder after liquid-solid fluidization shaping is carried out microscopic appearance observation (see image 3 ) and fluidity, oxygen content test. Among them, the Hall flow meter is used to test the powder fluidity, and the inert gas pulse infrared thermal conductivity method is used to test the powder oxygen conten...

Embodiment 2

[0023] Weigh 300g irregular hydrogenated dehydrogenation titanium powder (microscopic appearance such as figure 2 Shown), added to the stirring container, and then added 200ml of deionized water and titanium powder to mix evenly, in order to prevent the titanium powder from being oxidized in contact with air. Set the rotation speed to 30,000 rpm, liquid-solid fluidization shaping for 5 minutes, let it cool naturally for 10 minutes after shutting down, add the titanium powder mixture into the Buchner funnel to filter, and then take the filtered titanium powder and dry it in a vacuum drying oven at 70°C Dry for 5 hours and take the powder for vacuum packaging. The liquid-solid fluidized titanium powder was subjected to microscopic observation, fluidity and oxygen content test. Among them, the Hall flow meter is used to test the powder popularity and fluidity test. The Hall flow meter is used to test the powder oxygen content by the inert gas pulse infrared thermal conductivity...

Embodiment 3

[0025] Weigh 500g irregular hydrogenated dehydrogenation titanium powder (microscopic appearance such as figure 2 Shown), added to the stirring container, and then added 200ml of deionized water and titanium powder to mix evenly, in order to prevent the titanium powder from being oxidized in contact with air. Set the rotation speed to 30,000 rpm, liquid-solid fluidization shaping for 15 minutes, let it cool naturally for 10 minutes after shutting down, add the titanium powder mixture into the Buchner funnel to filter, and then take the filtered titanium powder and dry it in a vacuum drying oven at 70°C Dry for 5 hours and take the powder for vacuum packaging. The liquid-solid fluidized titanium powder was subjected to microscopic observation, fluidity and oxygen content test. Among them, the Hall flow meter is used to test the powder popularity and fluidity test. The Hall flow meter is used to test the powder oxygen content by the inert gas pulse infrared thermal conductivit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com