Device and method for preparing graphene

A technology of graphene and graphite, which is applied in the field of graphene preparation and application, can solve the problems of uneven oxidation distribution of materials, affect the quality of production, and small contact area, so as to improve reaction efficiency, ensure airtightness, and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

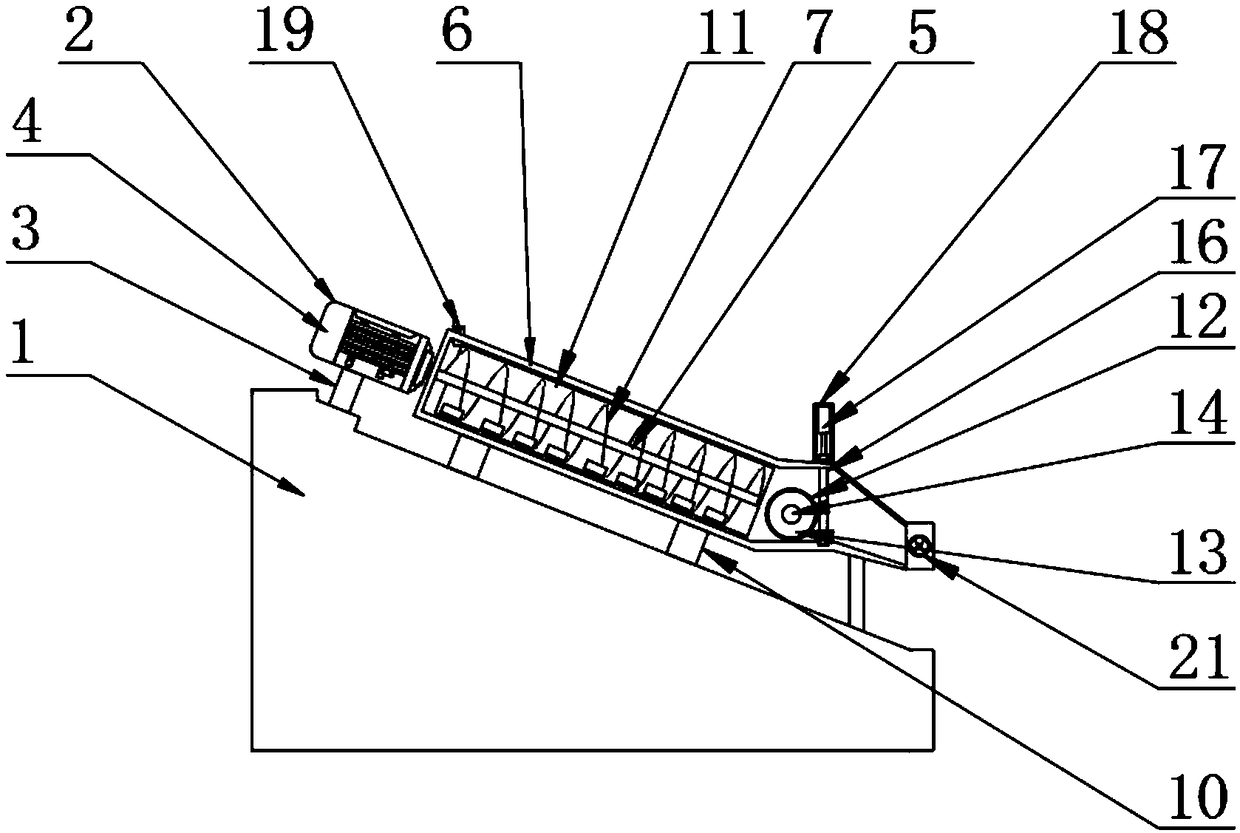

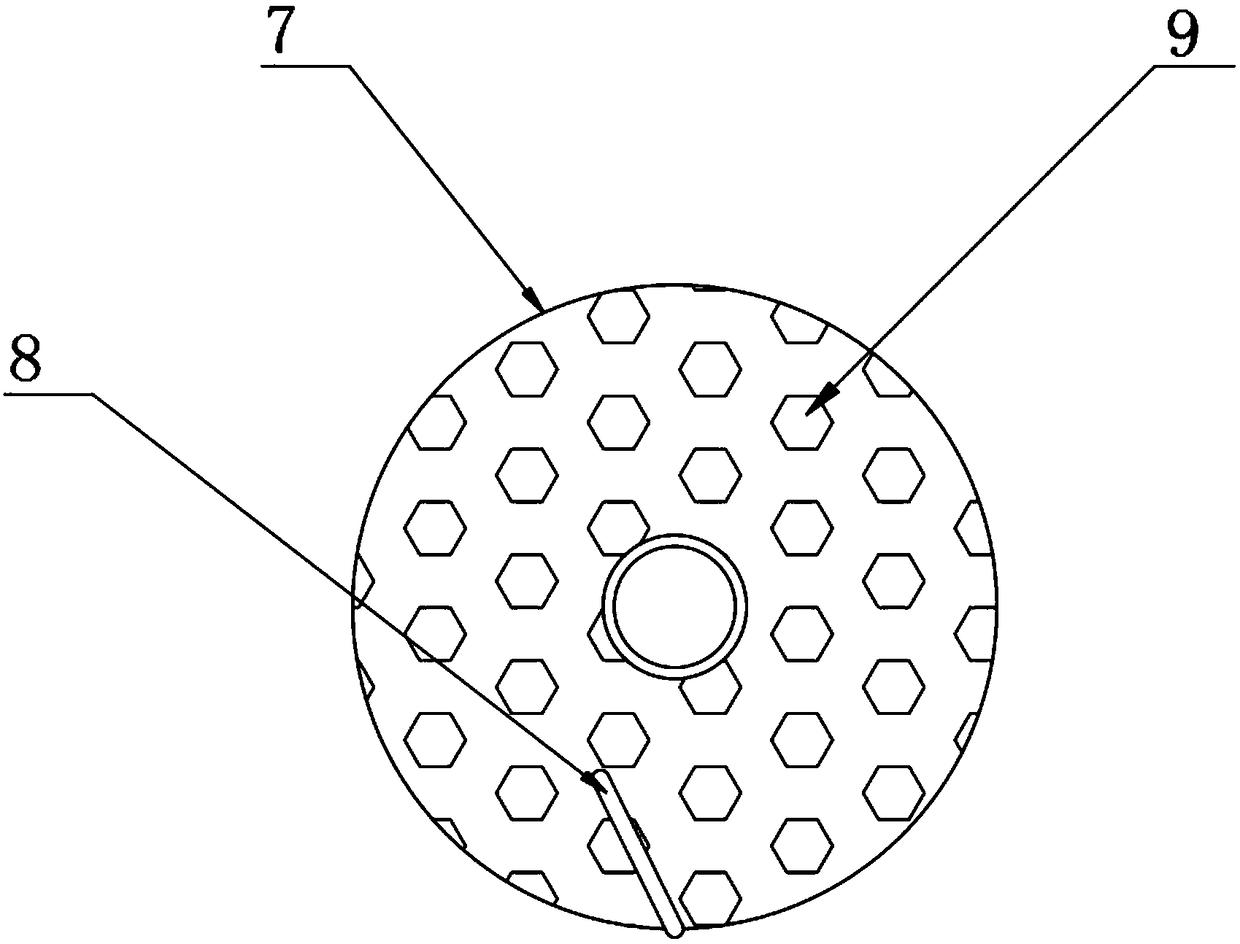

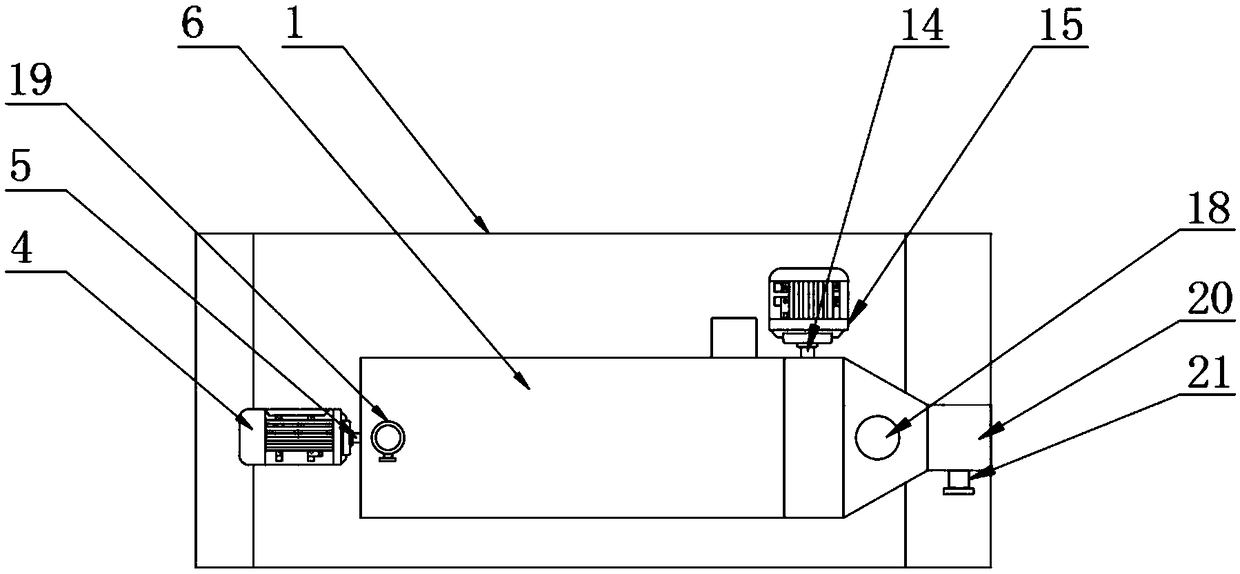

[0026] The present invention provides such Figure 1-3 A kind of device for preparing graphene shown, comprises base 1, and described base 1 top is provided with reaction device 2, and described reaction device 2 comprises first support bar 3, and described first support bar 3 is fixedly connected with base 1 , the top of the first support rod 3 is provided with a first motor 4, and one side of the first motor 4 is provided with a first rotating shaft 5, and the output shaft of the first motor 4 is fixedly connected with the first rotating shaft 5, and the first rotating shaft 5 is provided with a reaction box 6 on one side, the first rotating shaft 5 runs through the reaction box 6 and extends to the inside, the outer side of the first rotating shaft 5 is provided with a helical blade 7, and one side of the helical blade 7 is provided with a toggle plate 8 , the toggle plate 8 is fixedly connected with the spiral blade 7, the surface of the spiral blade 7 is provided with a l...

Embodiment 2

[0036] A method for preparing graphene, including the described device for preparing graphene, also includes the following steps:

[0037] S1: transporting the graphite raw material from the feed pipe 19 to the inside of the reaction box 6;

[0038] S2: Turn on the first motor 4 and the heater 11, the first motor 4 drives the spiral blade 7 to rotate in reverse, so that the graphite raw material is evenly distributed inside the reaction box 6, and the heater 11 heats the graphite raw material at the same time;

[0039] S3: The graphite raw material is dispersed through the leakage hole 9 on the surface of the spiral blade 7, and at the same time, the moving plate 8 moves the graphite raw material to the top of the reaction box 6;

[0040] S4: Turn on the second motor 15, and the reversely rotating second motor 15 drives the pulverizing wheel 13 through the second rotating shaft 14 to pulverize the graphite raw material, and at the same time pushes the graphite to the spiral bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com