Hot air leveling machining tool for ceramic-based printed circuit board and application of hot air leveling machining tool

A printed circuit board, hot air leveling technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of high brittleness, cracked ceramic-based printed circuit boards, low product yield and other problems, so as to improve the yield, The effect of reducing processing difficulty and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

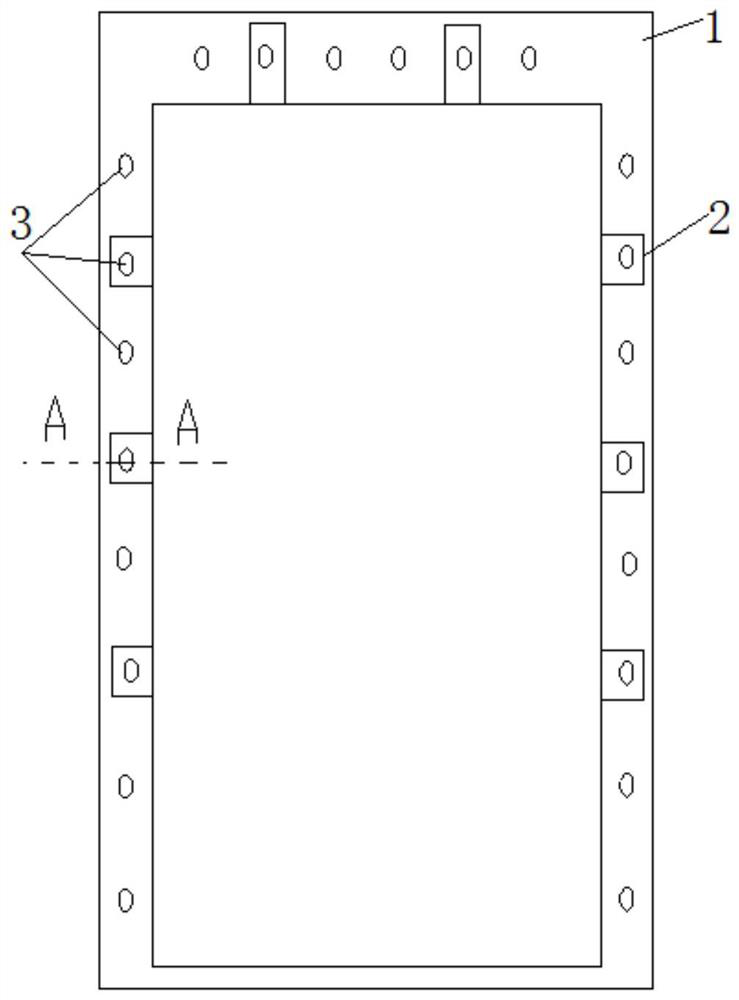

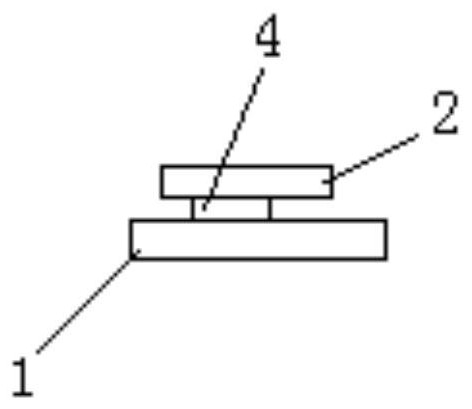

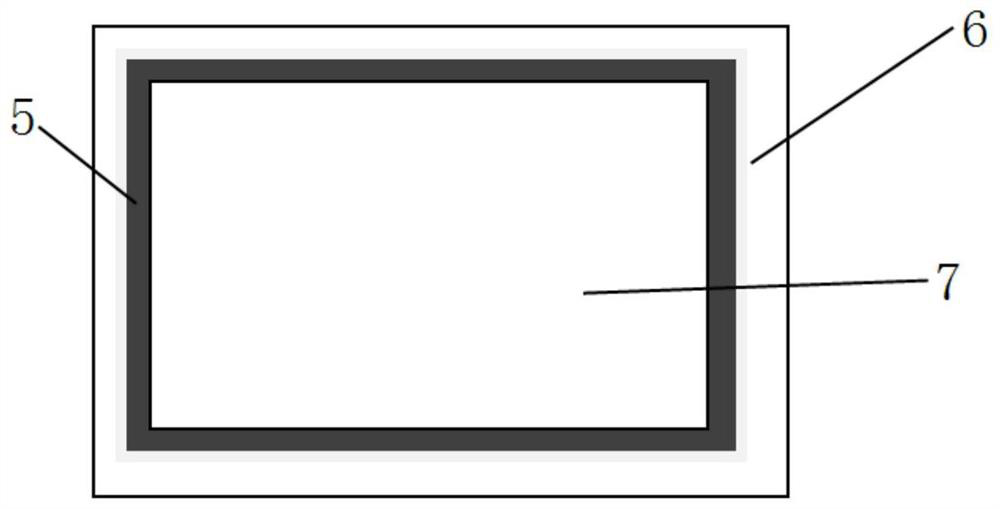

[0029] The hot air leveling processing method described in the present invention is suitable for ceramic-based printed circuit boards that require hot air leveling and tin-spraying processing.

[0030] A hot air leveling processing method for a ceramic-based printed circuit board of the present invention, specifically comprising the following steps:

[0031] Step 1, pre-processing;

[0032] The specific sequence is: board loading, the first washing, roughening, the second washing, pickling, the third washing, the fourth washing, the fifth washing, drying and cold wind blowing;

[0033] These operations are all done automatically in the pre-processing machine, in which the first water washing is to wet the ceramic-based printed circuit board, and the subsequent water washing is to remove impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com