Combined type shield hob cutter ring

A composite, hob technology, used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of reduced tunnel excavation radius, shield machine stuck, cutter head wear, etc., to reduce the probability of fracture, Avoid replacement, the effect of hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

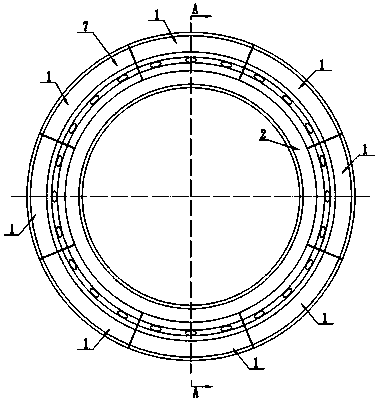

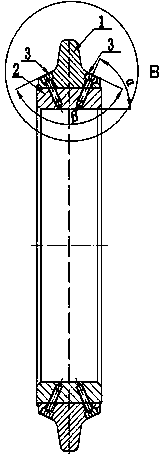

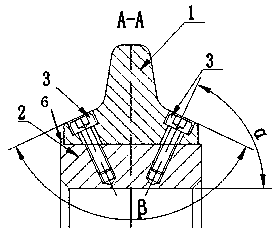

[0024] Such as Figure 1-3 As shown, a composite shield hob cutter ring includes an outer ring 7 and an inner ring 2, the outer ring 7 is fixedly connected to the inner ring 2, the inner ring 2 and the hob body 4 are connected by a positive fit, and the outer ring 7 is a split structure composed of a plurality of arc-shaped steel-bonded hard alloy blocks 1 , and a plurality of steel-bonded hard alloy blocks 1 are fixedly connected to the inner ring 2 .

[0025] In this embodiment, the steel-bonded hard alloy block 1 is fixed on the inner ring 2 by the bolt 3, and the inner ring 2 is provided with a limit step 6, and the bolt 3 cooperates with the limit step 6 to fix the steel on the inner ring 2. The cutting edge positions of the cemented carbide block 1 are aligned.

[0026] In this embodiment, the angle between the bolt 3 and the axis of the hob cutter ring is 60 degrees.

[0027] In this embodiment, the outer ring 7 is composed of 8 pieces with a hardness not less than HR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com