A controllable layered structure of nanodiamondene

A nano-diamondene and layered structure technology, applied in the direction of nanotechnology, diamond, etc., can solve the problems of low product quality, increase the distance between graphite layers, and high graphene production, and achieve good dispersion, high particle size concentration, and shape-controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

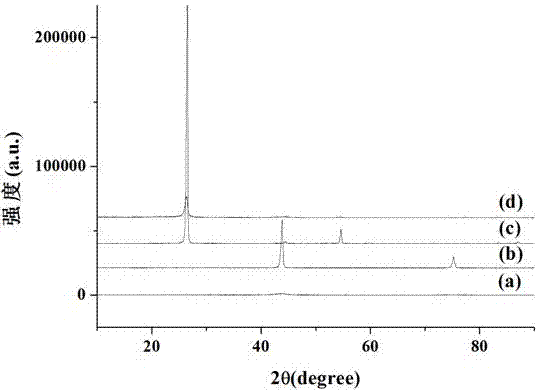

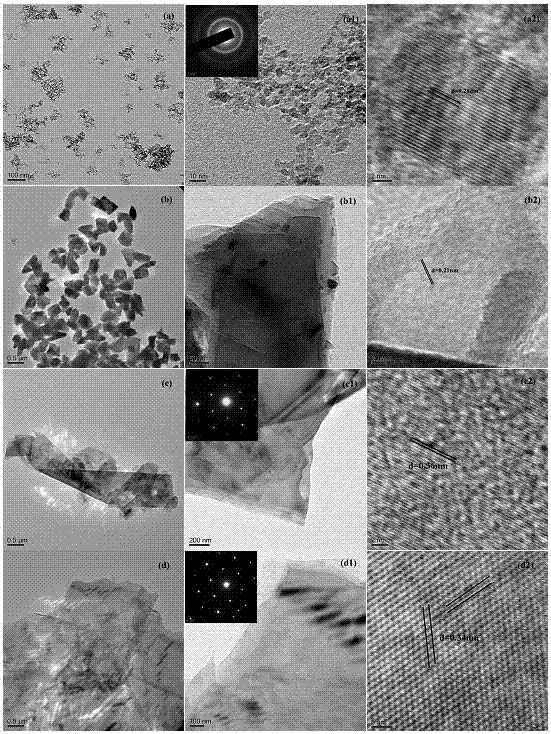

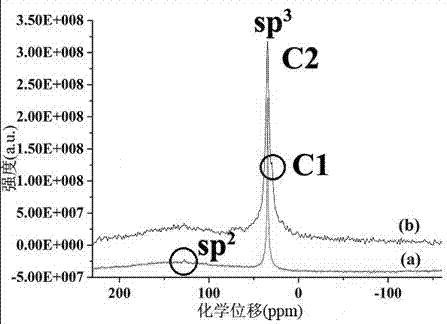

[0027] A new controllable layered structure of nanodiamondene, which is a layered single crystal structure, and the carbon atoms in the same layer are sp 3 Orbital hybrid carbon bond connection, carbon atoms between layers are sp 2 Hybrid carbon bond connection; particle size is R, 20≤R≤500nm, C content is 99-100%, lattice spacing is 0.21nm.

Embodiment 2

[0029] The above-mentioned nanodiamondene is prepared by the following process, the steps are:

[0030] (1) Preliminary crushing: the diamond raw material is sent into the ball mill shaping barrel, and after steel balls of different particle sizes are rotated back and forth at high speed for crushing and shaping, they pass through a screen with a certain mesh size at the receiving port of the ball mill. For collection, the mesh number of the screen is not less than 70 mesh, and the ball mill shaping time is generally controlled within 1-5h, and the 70 mesh coarse material is automatically returned to the ball mill for ball mill shaping; the collected particles above 70 mesh are passed through a multi-layer vibrating screen machine Carry out the primary particle size classification, the mesh number of the sieve is arranged from high to low from 100 mesh to 800 mesh, and the time of vibrating the sieve is generally 30min-2h, and finally collect the fine material filtered by the 8...

Embodiment 3

[0036] The difference between the preparation process of Example 3 and Example 2 lies in that: the centrifugation time is 2 hours, the rotation speed is 8000 rpm, and the precipitation and separation time is 1 day. The particle size of the prepared nanodiamantene is 100-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com