A kind of preparation method of ntc thermistor material ultrafine particle size

A thermistor, ultra-fine particle technology, applied in resistors with negative temperature coefficient, metal processing equipment, transportation and packaging, etc., can solve the problem of poor uniformity, long, generally 24 hours, or even longer, affecting the material. characteristics and other issues to achieve the effect of reducing the presence of unstable impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

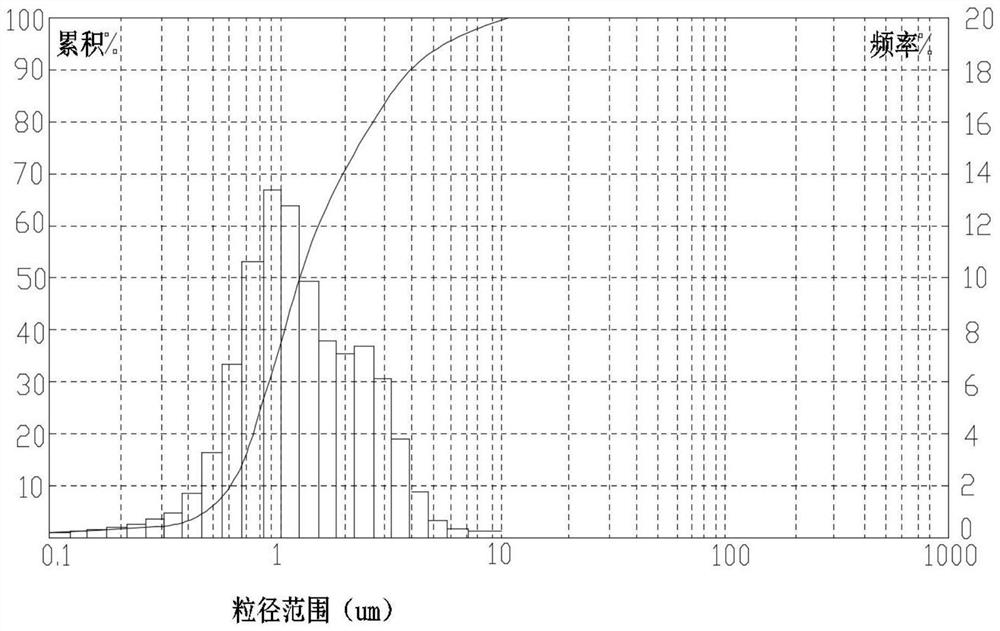

[0021] As an embodiment of the preparation method of the NTC thermistor material ultrafine diameter of the present invention, as figure 1 As shown, the NTC thermistor material adopts cobalt, nickel and iron powder as raw materials, including the following steps:

[0022] (1) Pour a sufficient amount of nitric acid analysis solution into a beaker, heat and keep it at 55°C-65°C;

[0023] (2) Divide the iron powder into multiple parts and gradually put them into the nitric acid analysis solution. At this time, there will be bubbles and smoke, and then enter the next step until there are no bubbles an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com