Wear-resisting cabinet table-board and manufacturing technology thereof

A production process and countertop technology, applied in the field of furniture, can solve problems such as leaving scratches, yellowing and discoloration of the countertop, cracking and damage of the countertop, etc., and achieve improved hardness and wear resistance, narrow particle size distribution, and particle size concentration high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

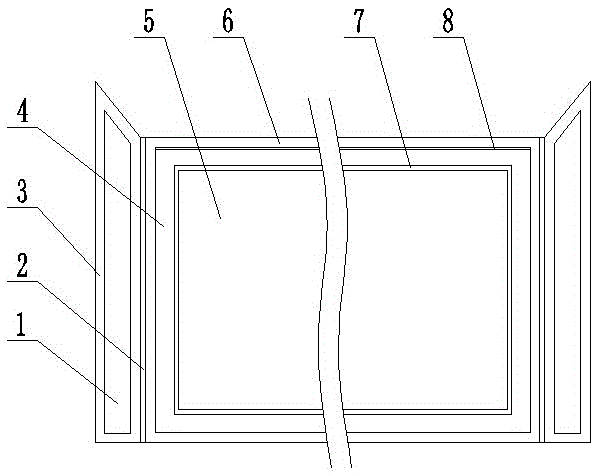

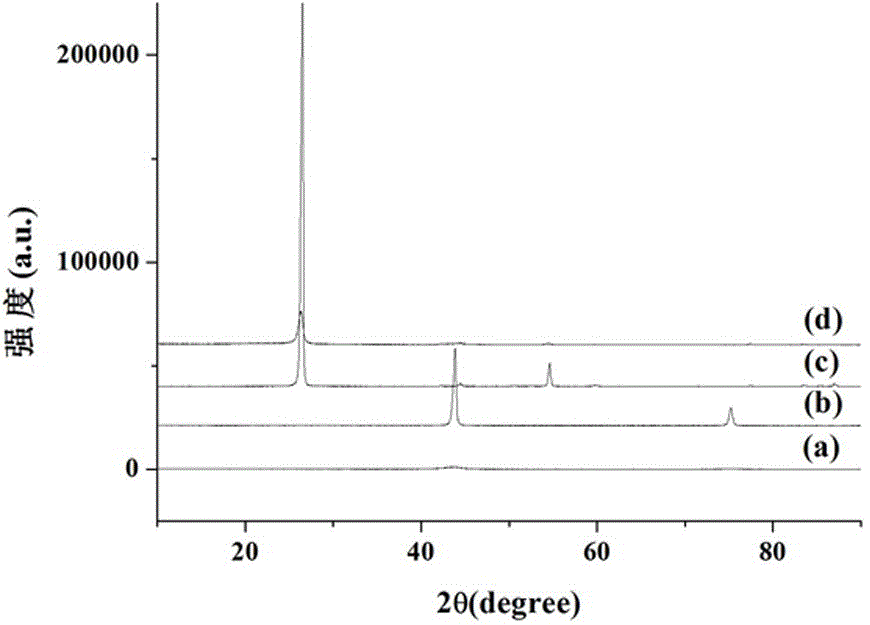

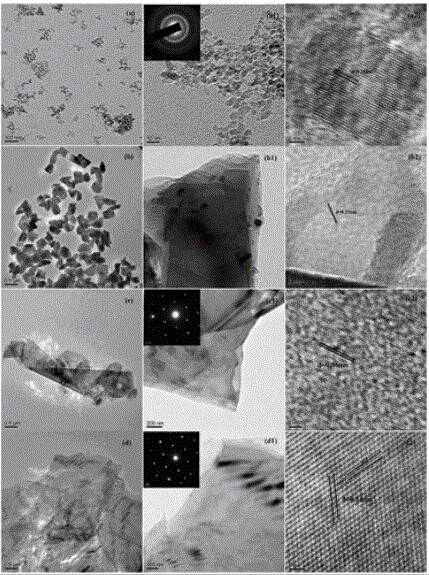

[0025] Wear-resistant cabinet countertops, including a wooden substrate 5, the outer surface of the wooden substrate 5 is fixed with a stainless steel layer 4 through a stainless steel bonding layer 7; the outer surface of the stainless steel layer 4 is coated with a diamond ene layer 6; the side of the diamond ene layer 6 is provided with a stainless steel stop Water bar; the outer surface of the stainless steel water bar 1 is coated with a water bar diamond layer 3; the water bar adhesive layer 2 is provided between the water bar diamond layer 3 and the diamond layer 6; the top surface of the stainless steel layer 4 Decorative layer 8 is arranged on it; the diamondene layer 6 and the water-retaining strip diamondene layer 3 are all composed of nanodiamondene with a lamellar single crystal structure; Interlayers are connected by sp3 orbital hybrid carbon bonds, and carbon atoms between layers are connected by sp2 hybrid carbon bonds; the lattice spacing of nanodiamondene is 0....

Embodiment 2

[0028] The average particle diameter of nanodiamondene is 300nm. The top of the stainless steel water retaining strip is an inclined plane, and the included angle between the inclined plane and the horizontal direction is 60°. The vertical distance between the top of the slope of the stainless steel water retaining strip and the diamond ene layer is 8mm. The thickness of the diamondene layer is 180 μm; the thickness of the water-retaining strip diamondene layer is 90 μm. The thickness of the stainless steel layer is 3mm; the thickness of the stainless steel water retaining strip is 2mm.

Embodiment 3

[0030] The average particle diameter of nanodiamondene is 200nm. The top of the stainless steel water retaining strip is an inclined plane, and the included angle between the inclined plane and the horizontal direction is 45°. The vertical distance between the top of the slope of the stainless steel water retaining strip and the diamond ene layer is 6mm. The thickness of the diamondene layer is 160 μm; the thickness of the water-retaining strip diamondene layer is 80 μm. The thickness of the stainless steel layer is 2mm; the thickness of the stainless steel water retaining strip is 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com