Composite diamond ene bone nail and its manufacturing method

A production method, the technology of diamondene, applied in medical science, surgery, coating, etc., can solve the problems of weak torsional strength, internal fixation looseness, deformation or fracture, etc., to slow down the degradation rate, facilitate free access, prevent Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

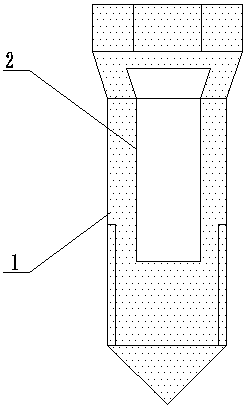

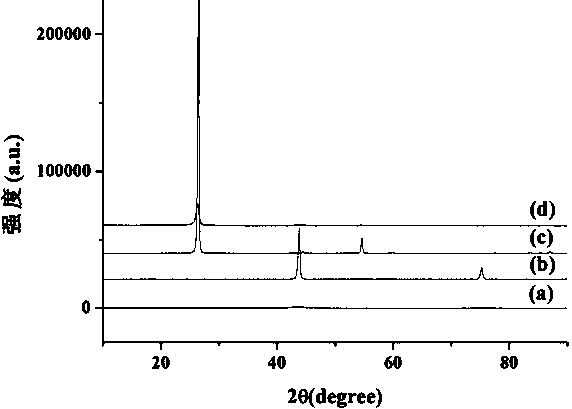

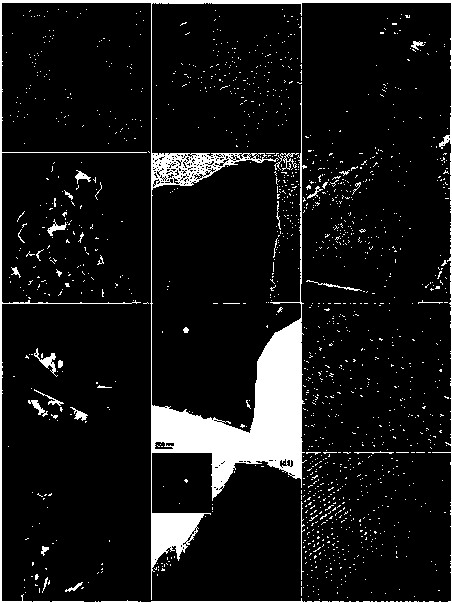

[0021] Composite diamond ene bone screws, such as figure 1 As shown, it includes the absorbable inner screw layer 2 and the composite diamondene layer 1 coated outside the absorbable inner screw layer 2, the ratio of the thickness of the composite diamondene layer 1 to the thickness of the absorbable inner screw layer 2 is 1; the composite diamondene layer Layer 1 is prepared from nano-diamantene with a sheet-like single crystal structure and absorbable materials. The carbon atoms in the same sheet of nano-diamantene are connected by sp3 orbital hybrid carbon bonds, and the carbon atoms between layers They are connected by sp2 hybrid carbon bonds; the lattice spacing of nano-diamantene is 0.21nm; the average particle size R of nano-diamantene is 20nm; the C content of nano-diamantene is 99-100%. The volume ratio of nanodiamondene to absorbable material in the composite diamondene layer 1 is 2:3. The absorbable inner screw layer 2 and the composite diamondene layer 1 have an i...

Embodiment 2

[0023] The difference between this embodiment and Example 1 is that the thickness of the composite diamondene layer is 1.2 times the thickness of the absorbable inner screw layer, the average particle size R of nanodiamondene is 500nm, and the nanodiamondene and absorbable material in the composite diamondene layer The volume ratio is 1:1.

Embodiment 3

[0025] The difference between this embodiment and Example 1 is that the thickness of the composite diamondene layer is 1.3 times the thickness of the absorbable inner screw layer, the average particle size R of nanodiamondene is 300nm, and the nanodiamondene and absorbable material in the composite diamondene layer The volume ratio is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com