A Synthetic Process for Improving Single Crystal Diamond Yield by Pronucleus Implantation

A technology of single crystal diamond and synthesis process, which is applied to the application of ultra-high pressure process, chemical instruments and methods, and the method of chemically changing substances by using atmospheric pressure. It can solve the problems of uneven particle size, high energy consumption, and uneven grade. advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

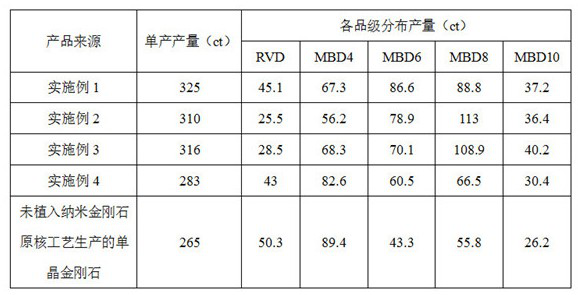

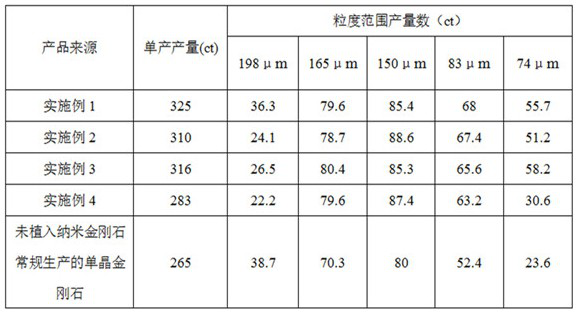

Embodiment 1

[0020] Embodiment 1: The process of producing single crystal diamond with a particle size range of 198-74 μm:

[0021] A kind of pronucleus implantation method improves the synthetic technique of monocrystalline diamond unit yield, comprises the steps:

[0022] 1. In the first step, the nano-diamond obtained by the explosion method is used as the pronucleus;

[0023] 2. In the second step, 30 parts per million of the diamond pronuclear raw material in the first step is mixed with 40%wt of metal catalyst and 40%wt of graphite carbon powder material. The metal catalyst is iron and nickel, wherein iron and nickel respectively account for 70%wt, 30%wt of catalyst component, described material is all prepared by weight ratio;

[0024] 3. In the third step, the three-dimensional mixing machine is used to mix the nano-diamond pronucleus, metal catalyst and graphite carbon powder materials evenly;

[0025] 4. In the fourth step, the materials in the third step are pressed by a doubl...

Embodiment 2

[0030] On the basis of Example 1, the second step scheme is adjusted to: 30 parts per million of the first step diamond pronuclear raw material, mixed with metal catalyst 45%wt, graphite carbon powder material 55%wt, the metal catalyst is Iron, nickel, and cobalt, wherein iron, nickel, and cobalt account for 72%wt, 26%wt, and 2%wt of the catalyst component respectively, and the materials are prepared by weight ratio; 310ct of single crystal diamond of 198-74μm can be obtained .

Embodiment 3

[0032] On the basis of embodiment 1, the second step scheme is adjusted to: 50 parts per million of the first step diamond pronuclear raw material, mixed with metal catalyst 50%wt, graphite carbon powder material 50%wt, the metal catalyst is Iron, nickel, and copper, wherein iron, nickel, and copper account for 68%wt, 26%wt, and 6%wt of the catalyst component respectively, and the materials are all prepared by weight ratio; 316ct of single crystal diamond of 198-74μm can be obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com