High-flux thermal evaporation film preparation device and application thereof

A technology of thin film preparation and thermal evaporation, applied in vacuum evaporation coating, from condensed steam, crystal growth, etc., can solve problems such as complex operation, reduce temperature difference, improve space utilization, and reduce possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

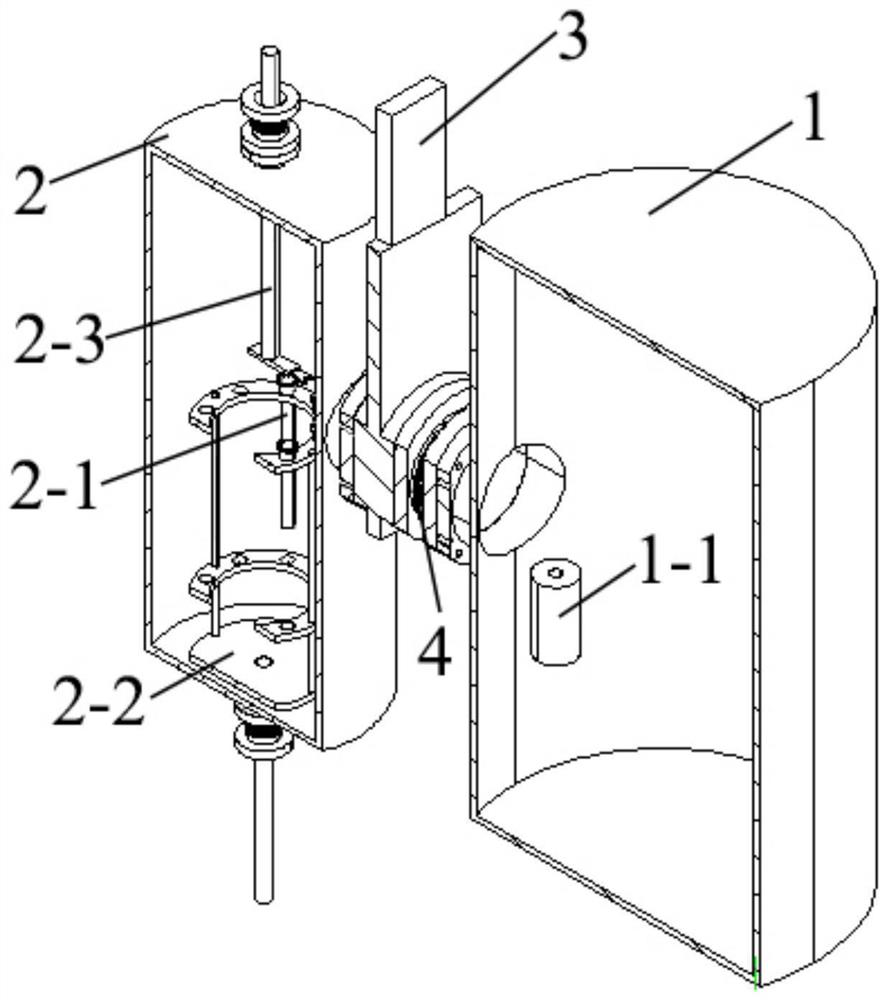

[0081] This embodiment provides a high-throughput thermal evaporation thin film preparation device, and the structural schematic diagram of the high-throughput thermal evaporation thin film preparation device is as follows figure 1 As shown, it includes an evaporation chamber 1 and a storage chamber 2 .

[0082] The evaporation chamber 1 communicates with the storage chamber 2 through a flexible connection pipeline 4 ; the communication pipeline between the evaporation chamber 1 and the storage chamber 2 is provided with a stopper 3 . The evaporation chamber 2 is provided with a thermal evaporation coating device system.

[0083] The evaporation chamber 1 is provided with a thermal evaporation source 1-1, and the thermal evaporation source 1-1 is provided with a concave cavity for placing the crucible 2-1.

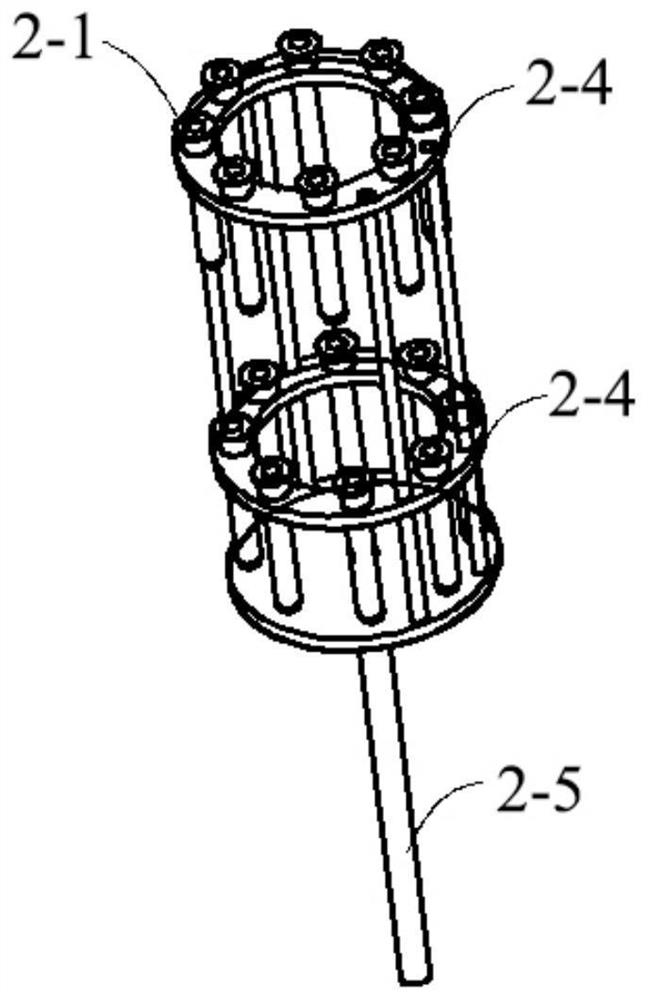

[0084] The storage chamber 2 is provided with a crucible storage rack 2-2 and a manipulator 2-3; the manipulator 2-3 is used for transporting the crucible 2-1 between the...

Embodiment 2

[0096] This embodiment provides a high-throughput thermal evaporation thin film preparation device, and the structural schematic diagram of the high-throughput thermal evaporation thin film preparation device is as follows figure 1 As shown, it includes an evaporation chamber 1 and a storage chamber 2 .

[0097] The evaporation chamber 1 communicates with the storage chamber 2 through a flexible connection pipeline 4 ; the communication pipeline between the evaporation chamber 1 and the storage chamber 2 is provided with a stopper 3 . The evaporation chamber 2 is provided with a thermal evaporation coating device system.

[0098] The evaporation chamber 1 is provided with a thermal evaporation source 1-1, and the thermal evaporation source 1-1 is provided with a concave cavity for placing the crucible 2-1.

[0099] The storage chamber 2 is provided with a crucible storage rack 2-2 and a manipulator 2-3; the manipulator 2-3 is used for transporting the crucible 2-1 between the...

Embodiment 3

[0111] This embodiment provides a high-throughput thermal evaporation thin film preparation device, and the structural schematic diagram of the high-throughput thermal evaporation thin film preparation device is as follows figure 1 As shown, including evaporation chamber 1 and storage chamber 2;

[0112] The evaporation chamber 1 communicates with the storage chamber 2 through a flexible connection pipeline 4 ; the communication pipeline between the evaporation chamber 1 and the storage chamber 2 is provided with a stopper 3 .

[0113] The evaporation chamber 1 is provided with a thermal evaporation source 1-1, and the thermal evaporation source 1-1 is provided with a concave cavity for placing the crucible 2-1.

[0114] The storage chamber 2 is provided with a crucible storage rack 2-2 and a manipulator 2-3; the manipulator 2-3 is used for transporting the crucible 2-1 between the thermal evaporation source 1-1 and the crucible storage rack 2-2 .

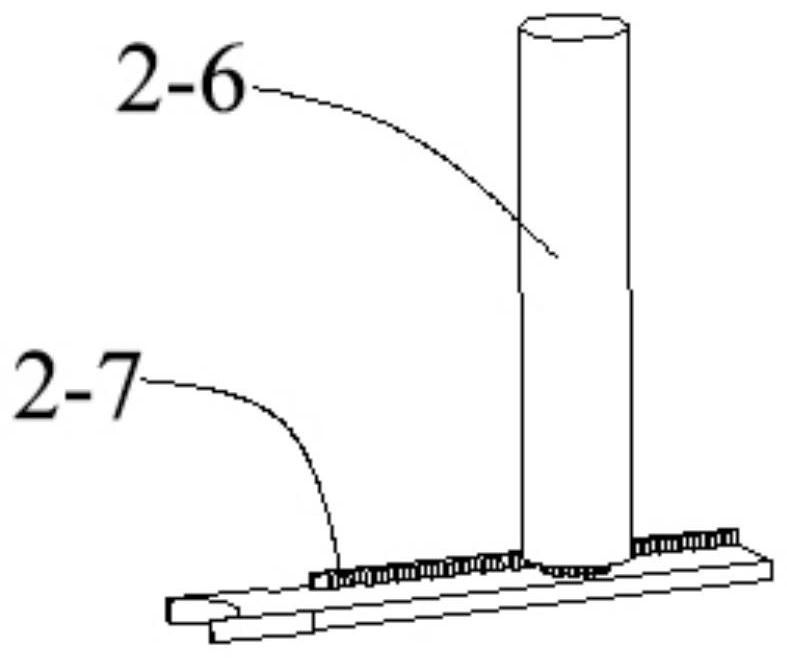

[0115] The structural rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com