Photovoltaic module, preparation method and application thereof

A photovoltaic module, a type of technology, applied in the field of photovoltaic modules and their preparation, can solve the problems of complex operation and insufficient reduction of the target area, and achieve the effects of improving aesthetics, saving production costs, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] An embodiment of the present invention provides a method for preparing a photovoltaic module, comprising the following steps:

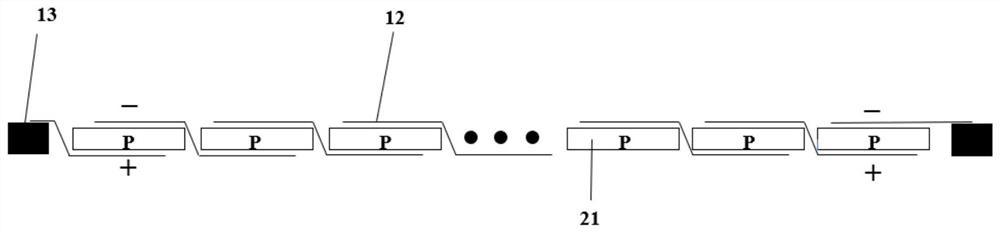

[0073] In step 1, a plurality of first battery slices are connected in series with second battery slices to obtain a battery string, and the first battery slices and the second battery slices are of different types.

[0074] Step 2: Connect one end of the flexible conductive material to the back electrode of the first battery slice corresponding to the positive pole of one battery string, and connect the other end to the back electrode of the second battery slice corresponding to the negative pole of the other battery string.

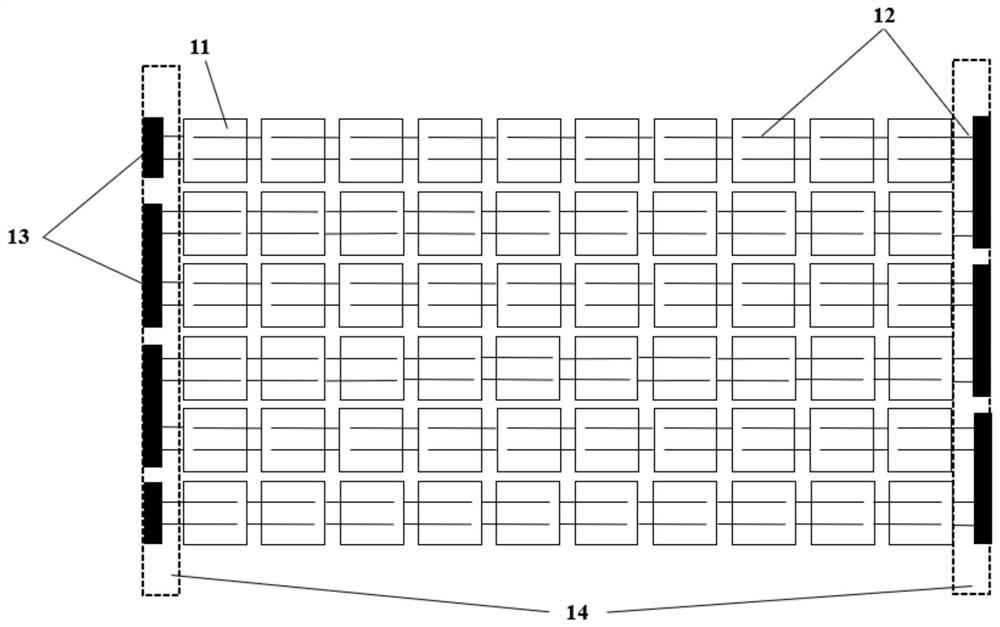

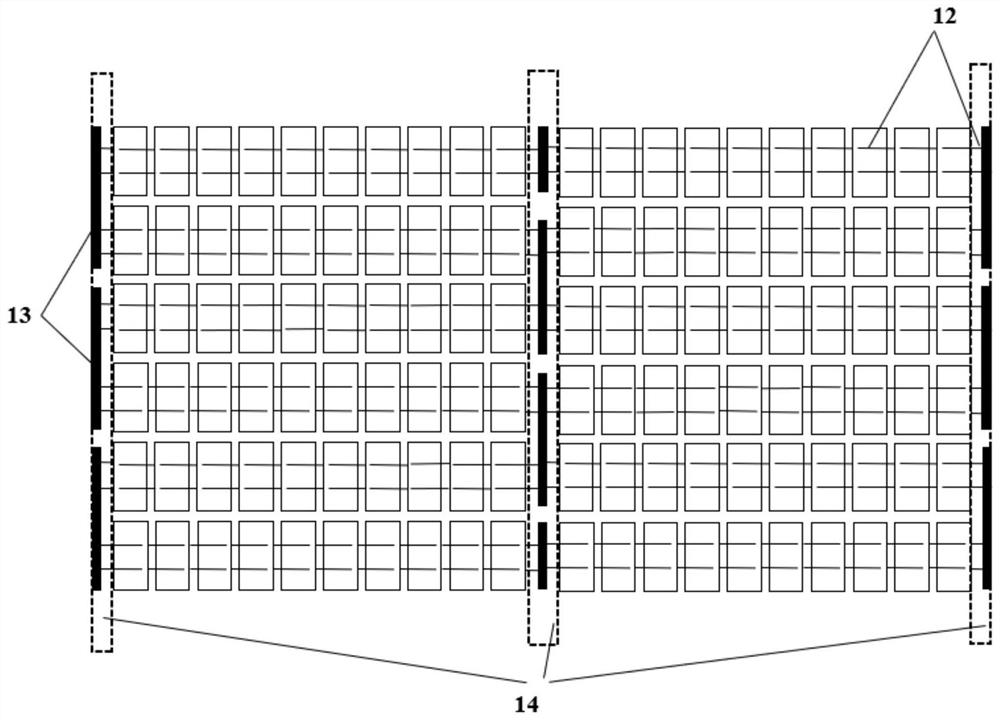

[0075] The method is suitable for preparing full-sheet assemblies, half-sheet assemblies or stitch-welded assemblies. in Figure 4 for the full-chip component, Figure 5 for half-chip components. Stitch welded assembly structure and Figure 4 or Figure 5 The structure in is similar, except that there are no gaps be...

Embodiment 1

[0090] 158.75mm×158.75mm 9BB double-sided PERC is used to make a 60-type single-glass module. The interconnection bar is a tin-coated interconnection bar with a diameter of 0.3mm, and the cross-section of the flexible bus bar is 14mm×0.15mm. Insert the battery string according to the Figure 4The connection sequence of the battery sheets in the middle is welded well, and the tails of the interconnection strips of the back electrodes of the two battery cells at the beginning and end of the battery string are crushed. The length and thickness are suitable for not affecting the welding quality and causing hidden cracks in the battery sheets, preferably 15-20mm long. After the thickness is flattened, it is between 0.1 and 0.2mm. Arrange the battery strings according to the stacked layout, and then weld the bus bar and the flattened interconnection bar with an electric soldering iron to connect two adjacent battery strings. , When welding, a gasket is required below to prevent the ...

Embodiment 2

[0092] 158.75mm×158.75mm 9BB double-sided PERC is used to make a 60-type single-glass module. The interconnection bar is a tin-coated interconnection bar with a diameter of 0.3mm, and the cross-section of the flexible bus bar is 14mm×0.15mm. Insert the battery string according to the Figure 4 The connection sequence of the middle cells is welded, and the silicone conductive adhesive containing pure silver conductive particles is evenly coated on the outermost back electrodes of the cells at both ends of the battery string, and then the bus bar is placed to connect the two adjacent battery strings in series , and then heated with a heating plate at 160°C for 10 minutes to cure the conductive adhesive. After lamination, no bus bars can be seen from the front, and no cracks were found in EL photographs. compared to Figure 1a In the design, the area of the component is reduced by 0.02m 2 , so the photoelectric conversion capability per unit area of the photovoltaic module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com