Dentistry gradient slope structure metal porcelain stuff and preparing method thereof

A gradient material and gradient structure technology, applied in the field of dental prosthesis, can solve problems such as metal-porcelain materials with no gradient structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

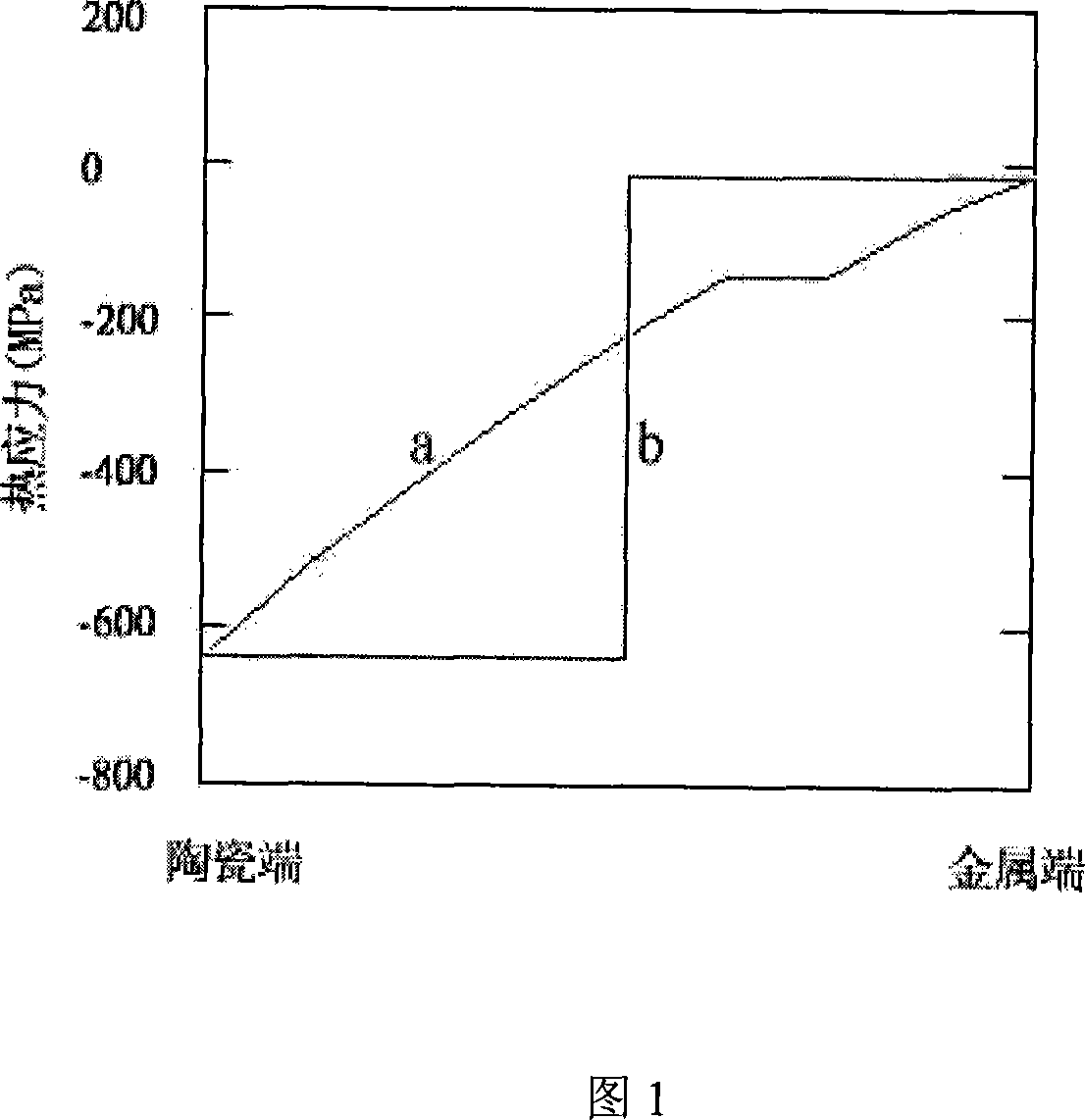

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The first step: the metal nickel, chromium and its oxide powder according to Ni:Cr:NiO:Cr 2 o 3 =40%: 10%: 0%: 50% mass ratio mixed, ground to make it mixed uniformly, as gradient adjustment component.

[0014] Step 2: Weigh 0.15 g of porcelain powder with an average particle size of 2 μm, and coat it on the metal substrate.

[0015] Step 3: Add 0.015 g (accounting for 10% by weight) of gradient adjustment components to 0.135 g of porcelain powder with an average particle size of 2 μm, mix evenly, and coat on the coating described in the second step.

[0016] Step 4: Add 0.03 g (20% by weight) of gradient adjustment components to 0.12 g of porcelain powder with an average particle size of 2 μm, mix evenly, and coat on the coating described in the third step.

[0017] Step 5: Add 0.045 g (accounting for 30% by weight) of gradient adjustment components to 0.105 g of porcelain powder with an average particle size of 2 μm, mix evenly, and coat on the coating described in ...

Embodiment 2

[0027] The first step: the metal nickel, chromium and its oxide powder according to Ni:Cr:NiO:Cr 2 o 3 =25%: 25%: 25%: 25% mass ratio mixing, grinding to make it mix uniformly, as gradient adjustment component.

[0028] Step 2: Weigh 0.15 g of porcelain powder with an average particle size of 2 μm, and coat it on the metal substrate.

[0029] Step 3: Add 0.015 g (accounting for 10% by weight) of gradient adjustment components to 0.135 g of porcelain powder with an average particle size of 2 μm, mix evenly, and coat on the coating described in the second step.

[0030] Step 4: Add 0.03 g (20% by weight) of gradient adjustment components to 0.12 g of porcelain powder with an average particle size of 2 μm, mix evenly, and coat on the coating described in the third step.

[0031] Step 5: Add 0.045 g (accounting for 30% by weight) of gradient adjustment components to 0.105 g of porcelain powder with an average particle size of 2 μm, mix evenly, and coat on the coating described i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com