Wafer lifting method

A technology of wafer and lifting movement, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as uneven charge distribution, affecting production efficiency and product yield, deviation or chip drop, etc., to reduce deviation or The probability of chip drop, the effect of improving production efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

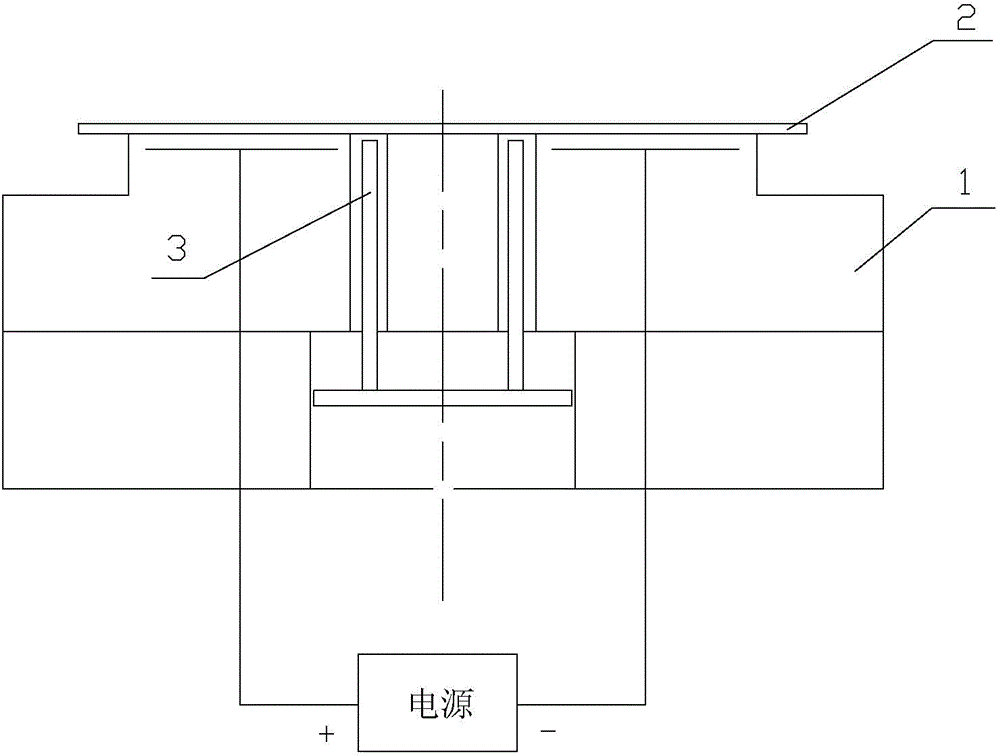

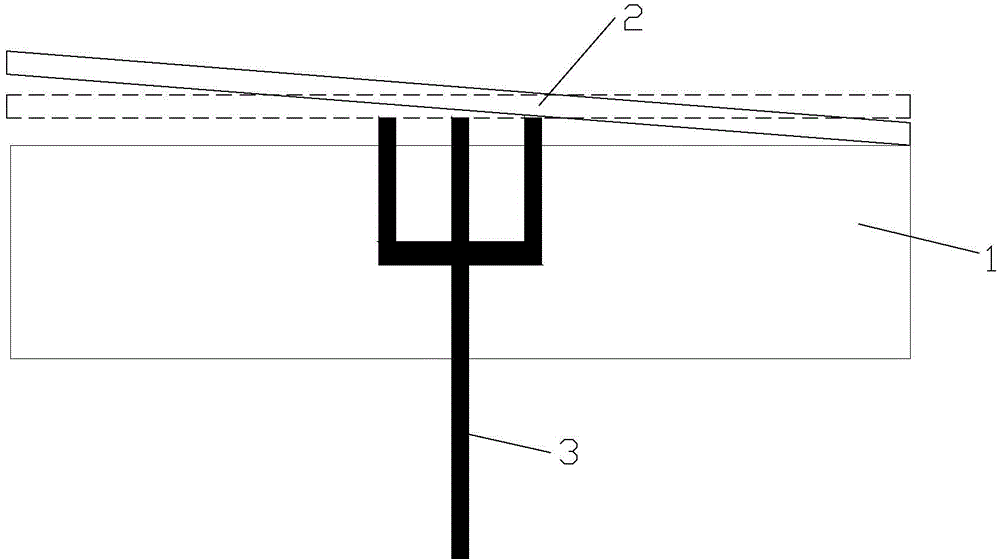

[0027] In order to make those skilled in the art better understand the technical solutions of the present invention, the wafer lifting method provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0028] The wafer lifting method provided by the embodiment of the present invention adopts the existing electrostatic chuck and thimble to realize the lifting of the wafer. The structures of the electrostatic chuck and the thimble have been described in detail in the above background art, and will not be repeated here.

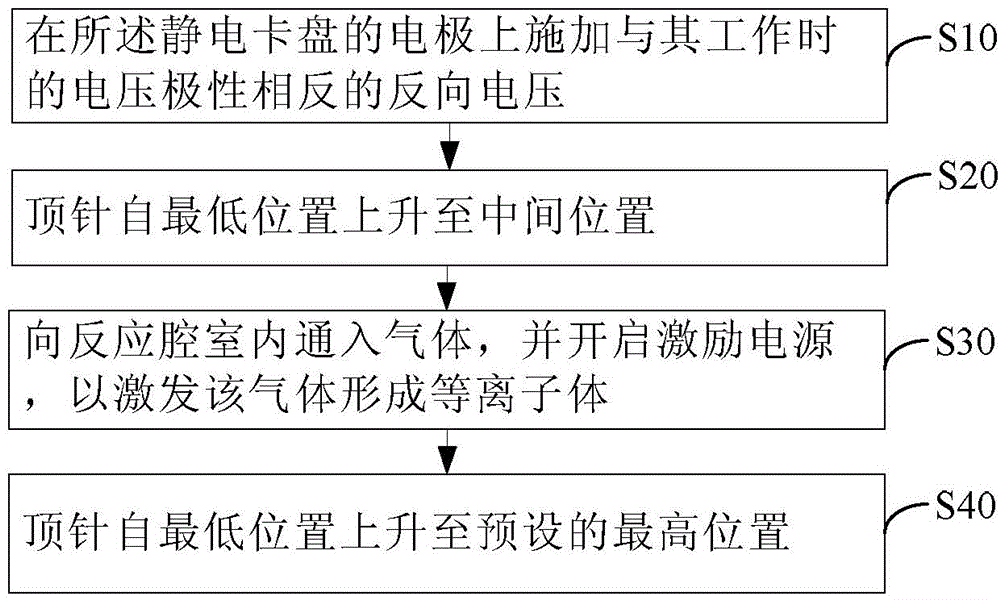

[0029] The wafer lifting method provided by the embodiment of the present invention is used to lift the wafer with an ejector pin after the process is completed, so as to release the wafer from the electrostatic chuck. Among them, after the process is over, it means after the wafer placed on the electrostatic chuck is processed; and, when the wafer is processed, a forward voltage is applied to the electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com