Industrialized recovery method and apparatus of waste liquid crystal display glass panel

A liquid crystal display and glass panel technology, which is applied in the industrial recycling and installation field of glass panels of waste liquid crystal displays, can solve the problems of large environmental side effects and low efficiency, and achieves the effects of high degree of automation, simple equipment maintenance and efficient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

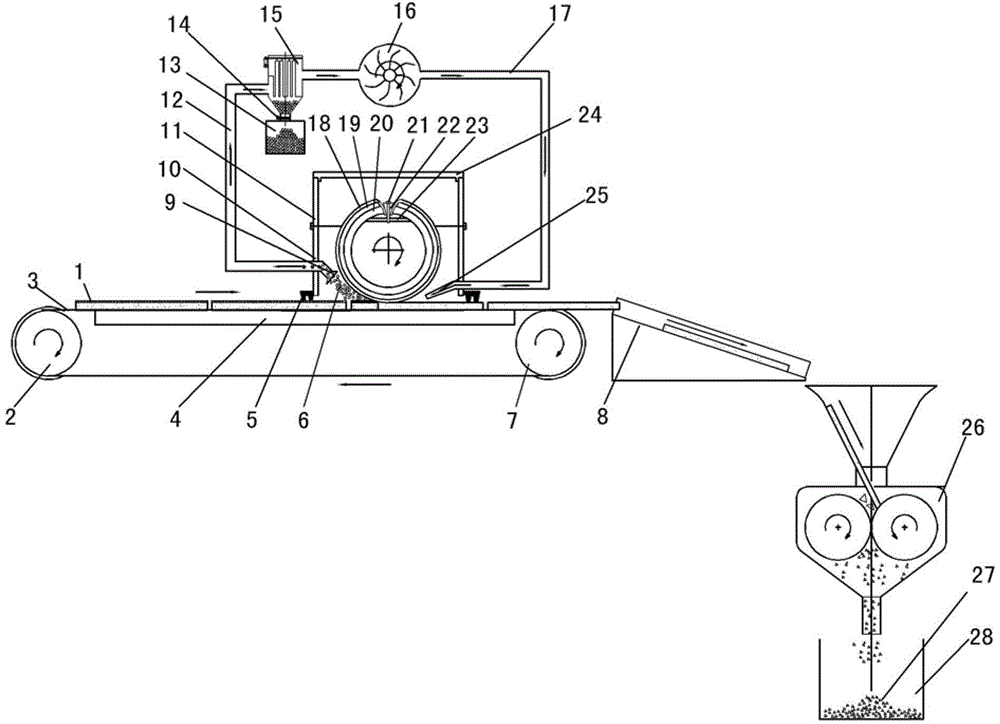

[0039] see figure 1 , the industrialized recycling method of the glass panel of the waste liquid crystal display in the present embodiment is to operate according to the following steps:

[0040] 1. Disassemble the liquid crystal display, take out the LCD glass panel, open the LCD glass panel by mechanical trimming, wash and remove the liquid crystal with a cleaning agent, and obtain two clean glass substrates 1, and clean the glass by hand or with a vacuum suction plate. The substrate 1 is placed on the horizontal conveyor belt 3 with the side where the film layer is located facing up;

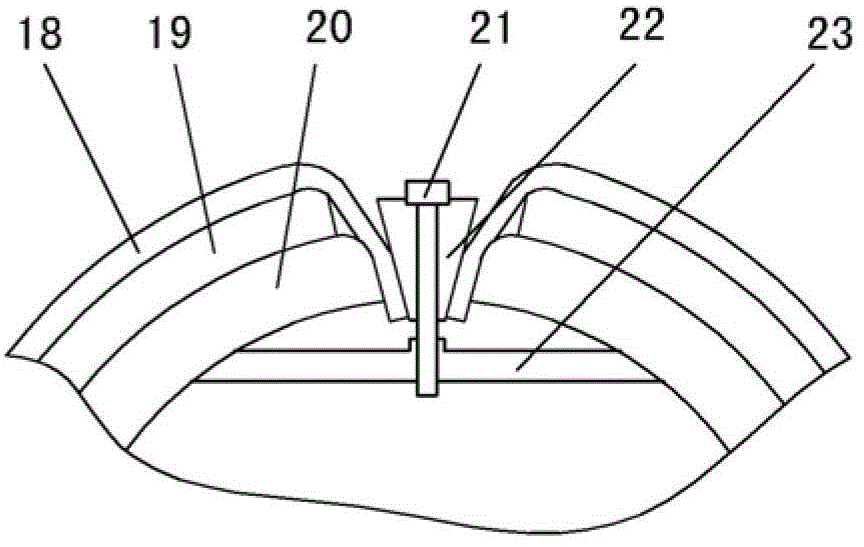

[0041]2. With the conveyance of the horizontal conveyer belt 3, when the glass substrate 1 passes under the grinding wheel, the film layer on the glass substrate 1 is ground by the grinding wheel, so that the film layer on the glass substrate 1 The film layer is separated from the glass substrate, and the film layer wear debris 6 is collected; the film layer wear debris 6 is collected by air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com