Process for preparing nano-starch powder

A nano-starch and powder technology, applied in nano-materials and nano fields, can solve the problems of biological characteristics of contaminated raw starch, uneven particle size distribution, uneven hydrolysis rate, etc., and achieves easy industrialization, easy handling, and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

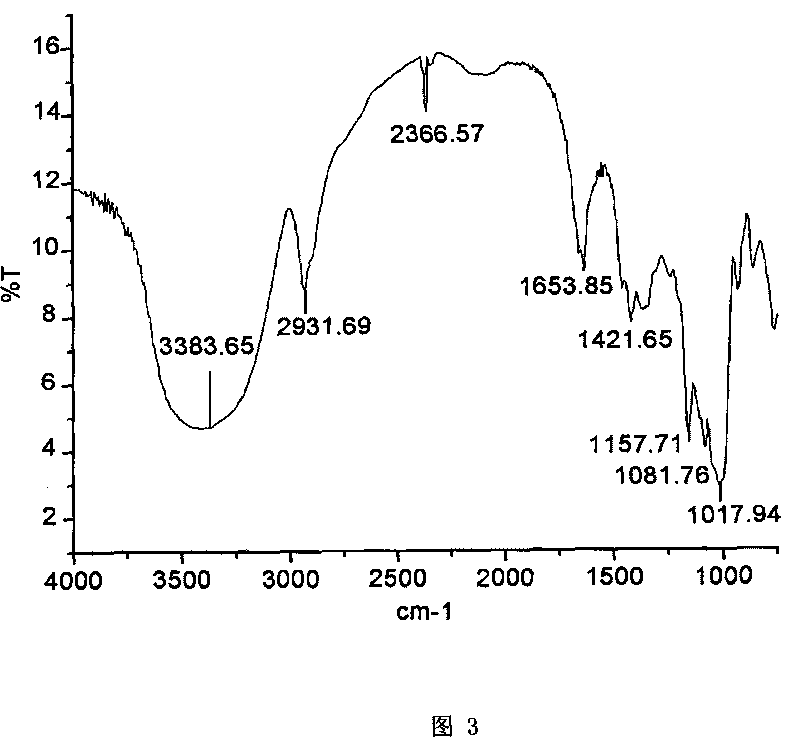

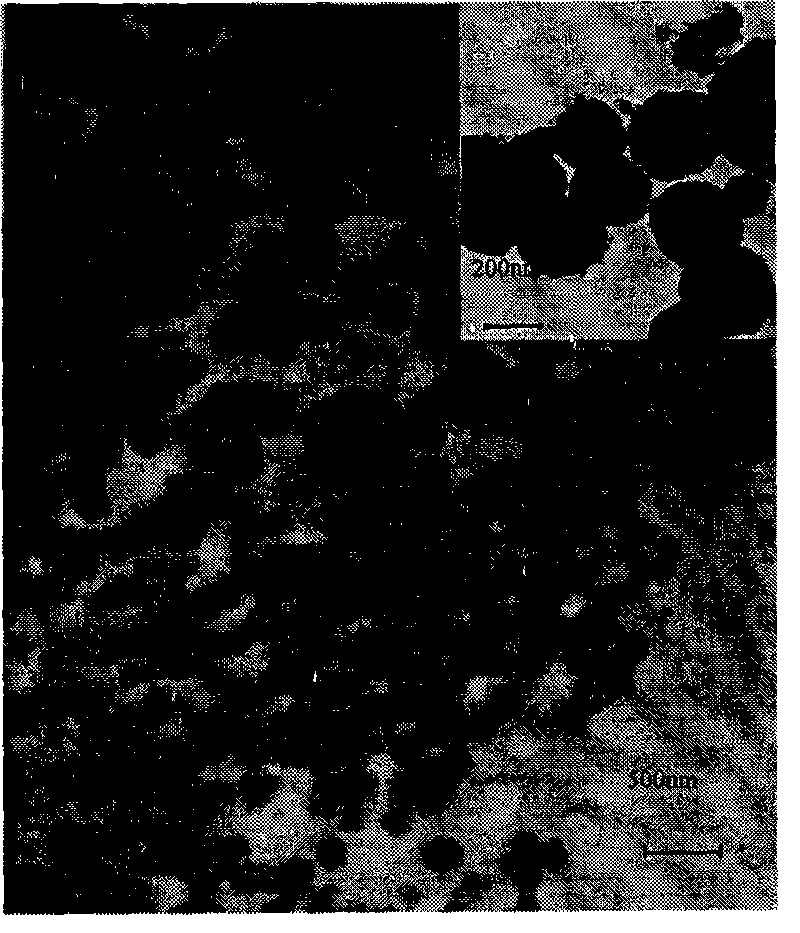

Embodiment 1

[0022] (1) In a container filled with deionized water, add 3‰ (mass percentage) sodium lauryl sulfate to dilute evenly, then add cornstarch and stir evenly, and the starch concentration in the solution is 8%;

[0023] (2) Place the radiation head of the high-energy ultrasonic wave in the middle of the starch solution, and set the program: the high-energy ultrasonic wave works for 5 seconds, with a 3-second break, and after 20 minutes of continuous work, there is a 10-minute break to complete a cycle. During the treatment process, the temperature in the solution should be observed to keep it lower than 50°C, and the intermittent time can be extended by increasing the temperature. After completing 5 cycles of work in this way (the actual effect of the ultrasonic wave is about 1 hour, and the whole process is about 4 hours), turn off the ultrasonic wave and take out the solution;

[0024] (3) Place the above solution in a water bath at 45°C, under the stirring of an electric stir...

Embodiment 2

[0028] (1) In a container filled with deionized water, add 5‰ (mass percentage) sodium lauryl sulfate to dilute evenly, then add cornstarch and stir evenly, and the starch concentration in the solution is 10%;

[0029] (2) Place the radiation head of the high-energy ultrasonic wave in the middle of the starch solution, and set the program: the high-energy ultrasonic wave works for 3 seconds, with a 2-second break, and after 25 minutes of continuous work, there is a 15-minute break to complete a cycle. During the treatment process, the temperature in the solution should be observed to keep it lower than 50°C, and the intermittent time can be extended by increasing the temperature. After completing 4 cycles of work in this way (the actual effect of the ultrasonic wave is about 1 hour, and the whole process is about 4 hours), turn off the ultrasonic wave and take out the solution;

[0030] (3) above-mentioned solution is placed in the water bath of 45 ℃, under the agitation of el...

Embodiment 3

[0034] (1) In a container filled with deionized water, add 5‰ (mass percentage) sodium lauryl sulfate to dilute evenly, then add cornstarch and stir evenly, and the starch concentration in the solution is 15%;

[0035] (2) Place the radiation head of the high-energy ultrasonic wave in the middle of the starch solution, and set the program: the high-energy ultrasonic wave works for 4 seconds, with an interval of 2 seconds. After 18 minutes of continuous work, there is an interval of 15 minutes to complete a cycle. During the treatment process, the temperature in the solution should be observed to keep it lower than 50°C, and the intermittent time can be extended by increasing the temperature. After completing 8 cycles of work in this way (the actual effect of the ultrasonic wave is about 1.5 hours, and the whole process is about 5 hours), turn off the ultrasonic wave and take out the solution;

[0036] (3) above-mentioned solution is placed in the water bath of 48 ℃, under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com