Door seal and manufacturing method thereof

A technology of sealing rubber and elastic parts, which is applied in the field of door seals and its preparation, can solve the problems of poor elasticity of PVC door seal materials, easy migration of plasticizers, and poor sealing performance, so as to achieve no increase in mold costs, reduce flash cracks, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

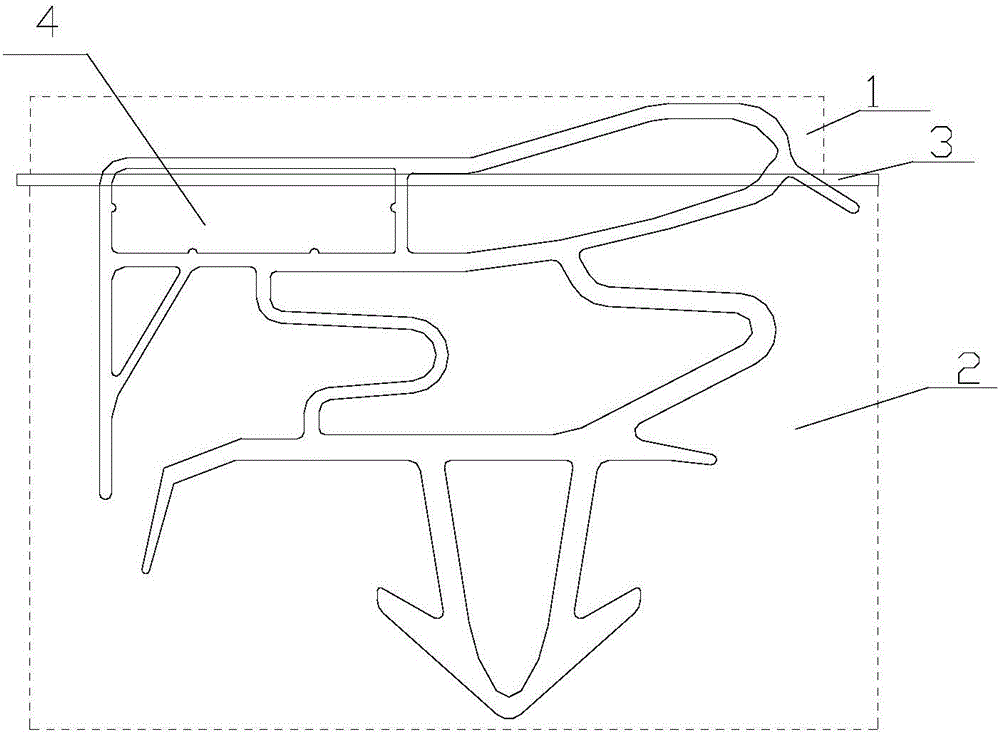

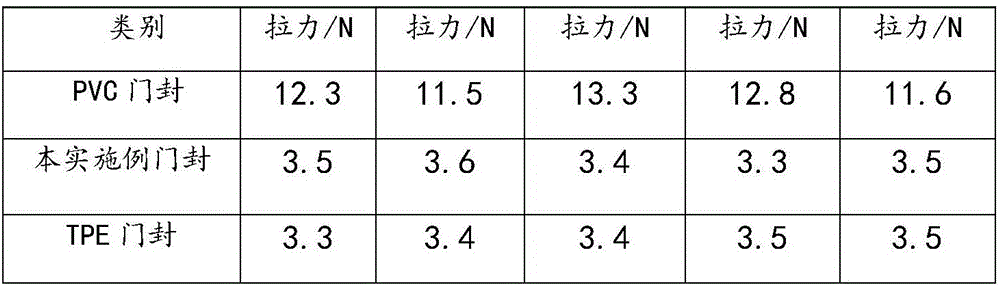

[0030] Such as figure 1 As shown, a door seal of this embodiment is co-extruded from two different materials, specifically including a door seal part 2 and an elastic part 1 formed by co-extrusion heat fusion, and the elastic part 1 is installed on the door. One end of the door seal part 2 is integrally seamlessly connected with the elastic part 1, and the other end is crimped on the door frame. The door seal part is made of PVC material, and the elastic part 1 is made of thermoplastic elastomer material; the door seal part A cavity 4 is formed between the part 2 and the elastic part 1, and a magnetic strip is arranged in the cavity 4. The door seal of this embodiment is made of elastomer material, so that the sealing performance between the door seal and the refrigerator is better. The physical and chemical reaction between the elastomer material and the coating of the refrigerator side panel is zero, which completely solves the problem of the adhesion between the refrigerat...

Embodiment 2

[0041] Such as figure 1As shown, a door seal of this embodiment is co-extruded from two different materials, specifically including a door seal part 2 and an elastic part 1 formed by co-extrusion heat fusion, and the elastic part 1 is installed on the door. One end of the door seal part 2 is integrally seamlessly connected with the elastic part 1, and the other end is crimped on the door frame. The door seal part 2 is made of PVC resin, and the elastic part 1 is made of thermoplastic elastomer material; A cavity 4 is formed between the sealing part 2 and the elastic part 1, and a magnetic strip is arranged in the cavity 4. The door seal of this embodiment is made of elastomer material, so that the sealing performance between the door seal and the refrigerator is better. The physical and chemical reaction between the elastomer material and the coating of the refrigerator side panel is zero, which completely solves the problem of the adhesion between the refrigerator side panel...

Embodiment 3

[0052] Such as figure 1 As shown, a door seal of this embodiment is co-extruded from two different materials, specifically including a door seal part 2 and an elastic part 1 formed by co-extrusion heat fusion, and the elastic part 1 is installed on the door. One end of the door seal part 2 is integrally seamlessly connected with the elastic part 1, and the other end is crimped on the door frame. The door seal part 2 is made of PVC resin, and the elastic part 1 is made of thermoplastic elastomer material; A cavity 4 is formed between the sealing part 2 and the elastic part 1, and a magnetic strip is arranged in the cavity 4. The door seal of this embodiment is made of elastomer material, so that the sealing performance between the door seal and the refrigerator is better. The physical and chemical reaction between the elastomer material and the coating of the refrigerator side panel is zero, which completely solves the problem of the adhesion between the refrigerator side pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com