Intelligent power cable with identity identification mechanism

A technology of identity identification and intelligent power, which is applied to power cables with shielding layers/conductive layers, insulated cables, cables, etc., can solve problems such as impact on life and production, consume a lot of time and manpower, and affect work efficiency. The effect of simple operation, safe protection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 An intelligent power cable with an identity identification mechanism

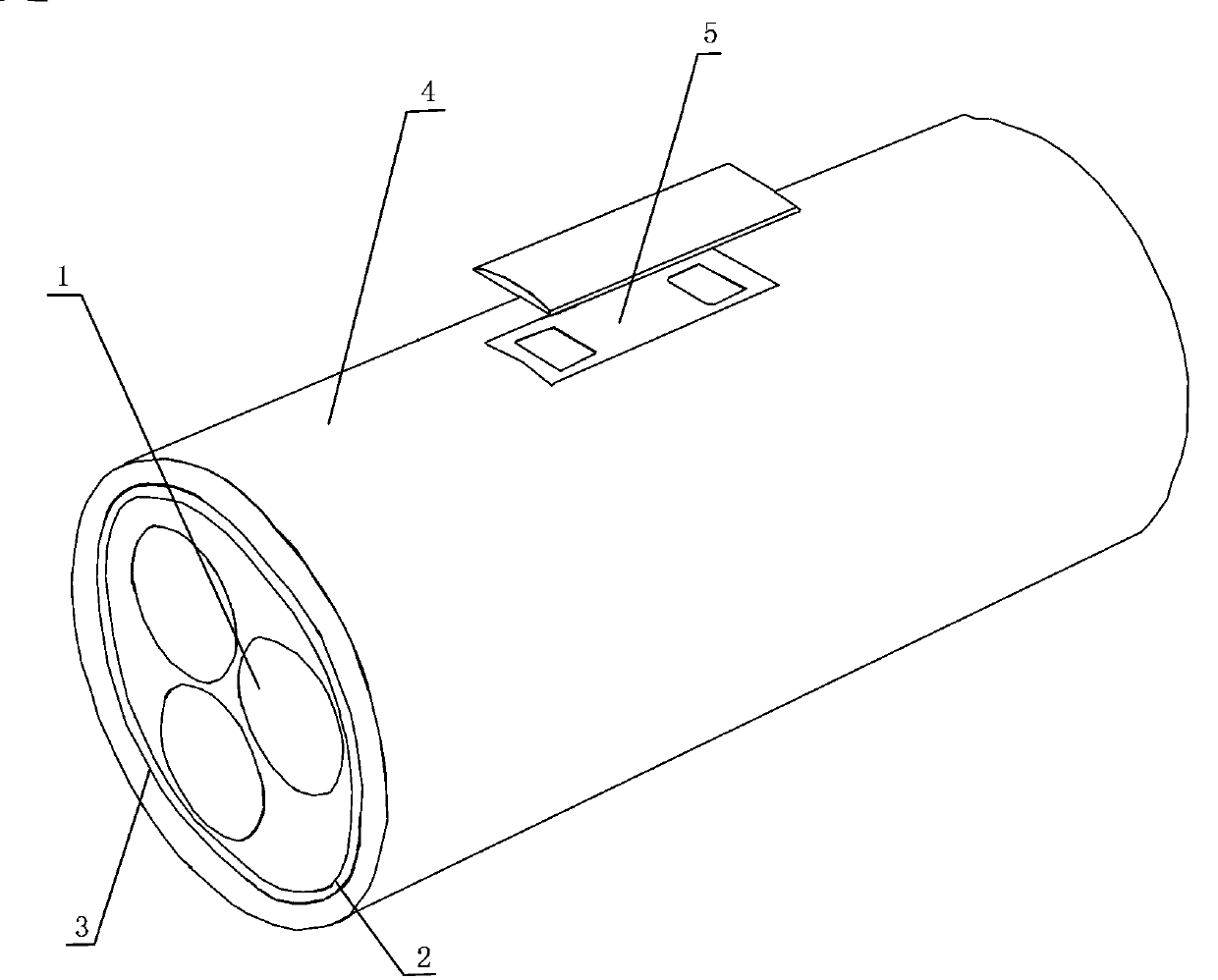

[0030] An intelligent power cable with an identity identification mechanism provided in this embodiment, such as figure 1 As shown, it includes cable core 1. The cable core 1 is used as a transmission carrier to transmit power, and the number of cores can be any number of cores in the prior art. This embodiment is a three-core cable.

[0031] In order to prevent the signal from being interfered by external signals during transmission, an insulating layer 2 and a shielding layer 3 are sequentially wrapped outside the cable core 1. At the same time, in order to protect the safety of the cable core 1, insulating layer 2, and shielding layer 3, An outer sheath 4 is also wrapped outside the shielding layer 3, and the outer sheath 4 is provided with an identification mechanism 5, and the identification mechanism 5 corresponds to the unique identity information of the cable (similar to the ID ...

Embodiment 2

[0036] Embodiment 2 An intelligent power cable with an identification mechanism

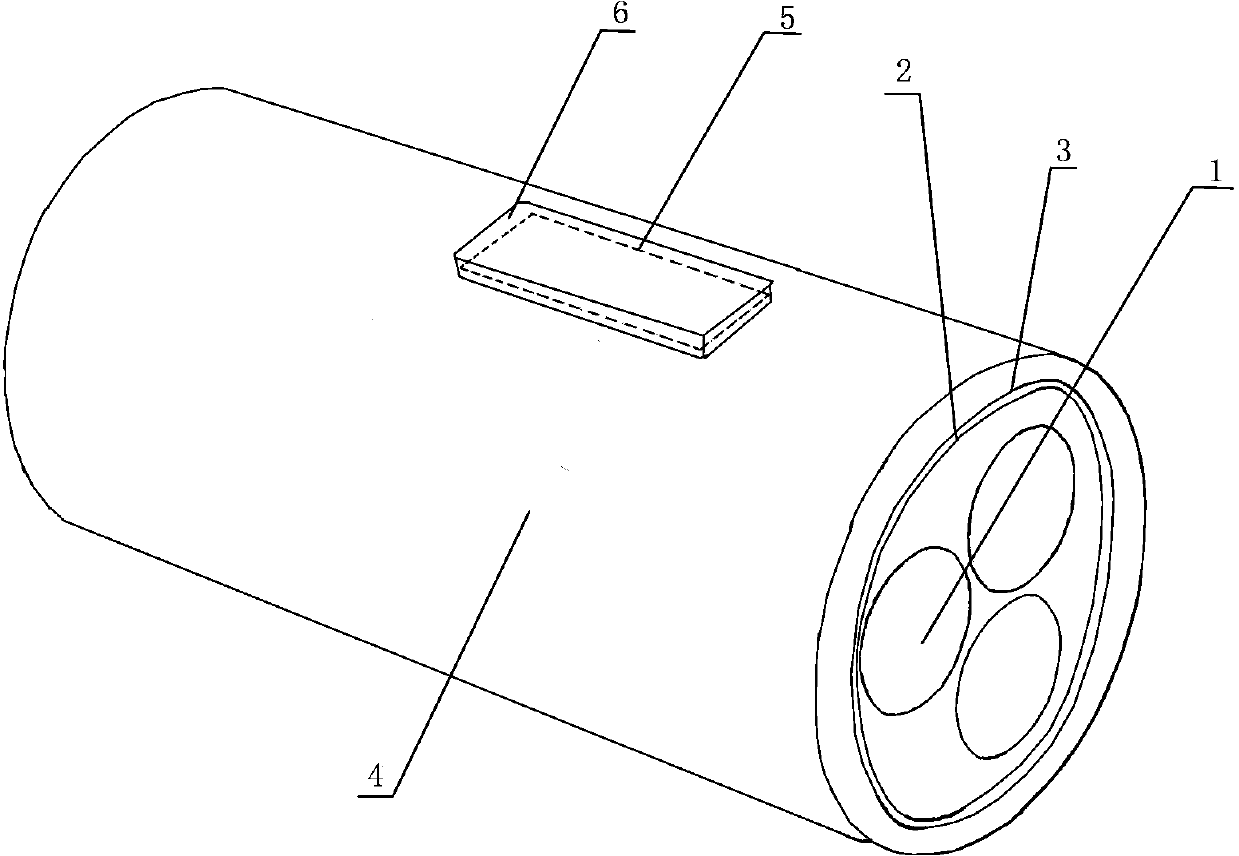

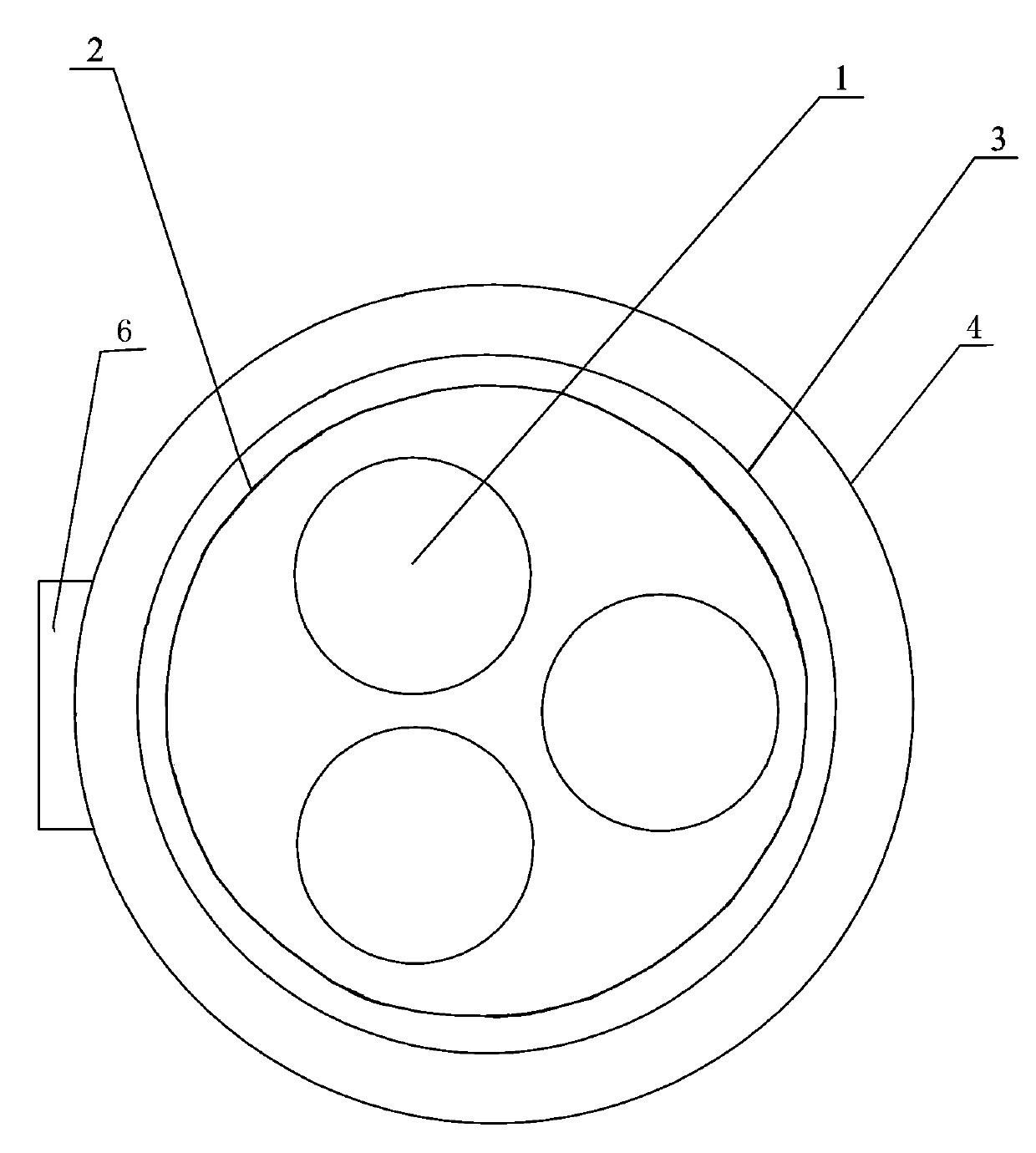

[0037] An intelligent cable with an identity identification mechanism provided in this embodiment is the same as the first embodiment, including a cable core 1, and an insulating layer 2, a shielding layer 3 and an outer sheath 4 are sequentially wrapped outside the cable core 1, Similarly, an identification mechanism 5 is provided on the outer sheath 4 .

[0038] The difference between this embodiment and the first embodiment lies in that the identification mechanism 5 in this embodiment is arranged in the casing 6 and then fixed on the outer surface of the outer sheath 4 through the casing 6 .

[0039] Wherein, the housing 6 includes an upper housing and a lower housing, and the upper housing and the lower housing can accommodate the identification mechanism 5 after being combined. For ease of installation, such as image 3 As shown: in this embodiment, the side of the lower casing in contact...

Embodiment 3

[0042] Embodiment 3 An intelligent power cable with an identity identification mechanism

[0043] An intelligent cable with an identity identification mechanism provided by this embodiment is the same as Embodiment 1 and Embodiment 2, including a cable core 1, and an insulating layer 2, a shielding layer 3 and an outer cable core 1 are sequentially wrapped outside the cable core 1. The sheath 4 is also provided with an identification mechanism 5 on the outer sheath 4 .

[0044] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the identification mechanism 5 in this embodiment is a barcode barcode used in the prior art. After the production of the cable is completed, the staff directly engraves it by laser. Alternatively, the barcode may be engraved or printed on the outer surface of the outer sheath 4 by means of ink printing. However, the reading of the barcode information during the cable follow-up maintenance or reconstruction process is exac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com