Horizontal-line multi-washing serial washing overflow structure

A horizontal line and water washing technology, which is applied in the cleaning/polishing of conductive graphics, secondary treatment of printed circuits, etc., can solve the problems of water waste, high pressure on enterprises, and very large demand for water consumption, and achieve the effect of low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings.

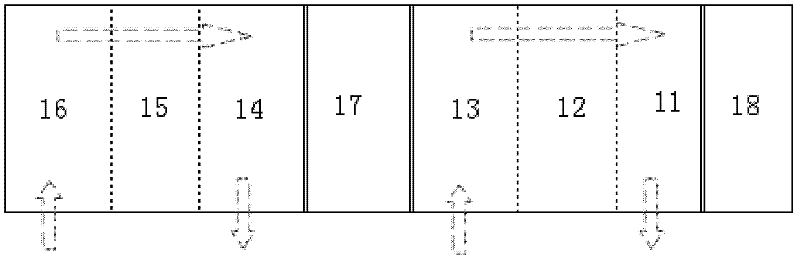

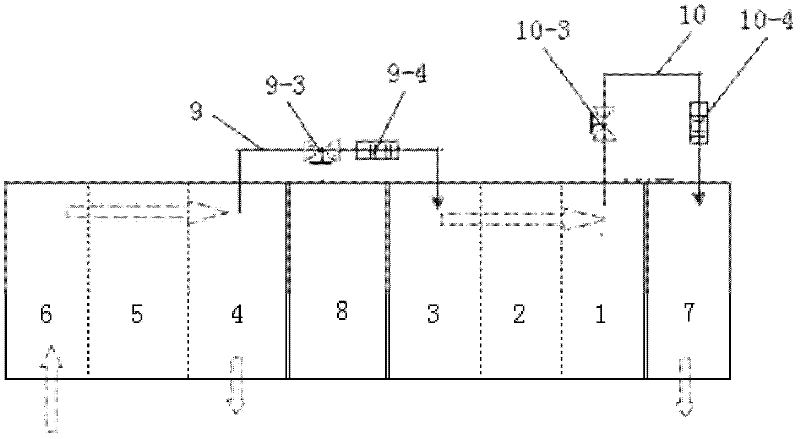

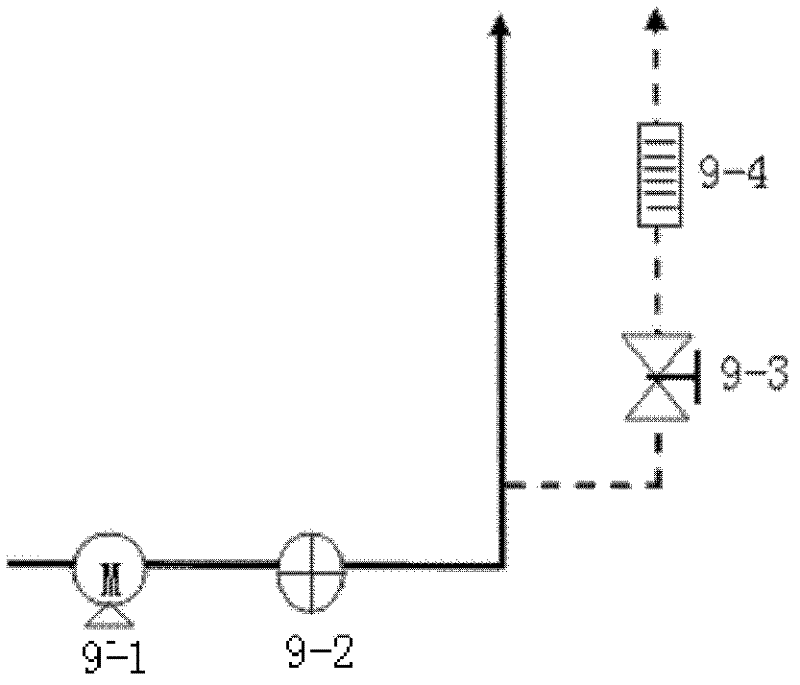

[0015] Such as Figure 2 ~ Figure 4 Shown: The horizontal line multi-channel washing series water washing overflow structure includes the first stage washing tank 1, the second stage washing tank 2, the third stage washing tank 3, the fourth stage washing tank 4, the fifth stage washing tank 5, and the sixth stage. Stage washing tank 6, spray pipe 7, anti-oxidation zone 8, first bypass pipeline 9, first washing pump 9-1, first filter device 9-2, first valve 9-3, first flow meter 9-4. The second bypass pipeline 10, the second washing pump 10-1, the second filtering device 10-2, the second valve 10-3, the second flow meter 10-4, etc.

[0016] The present invention includes a first washing zone and a second washing zone. An anti-oxidation zone 8 is provided between the first washing zone and the second washing zone. The first washing zone includes a first-stage washing tank 1 , The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com