Preparation method for molybdenum-antimony co-doped titanium-based stannic oxide electrocatalysis electrode

A tin dioxide and co-doping technology, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problem of high price, and achieve the effects of thorough treatment, simple and controllable preparation method, and easy large-scale electrode preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

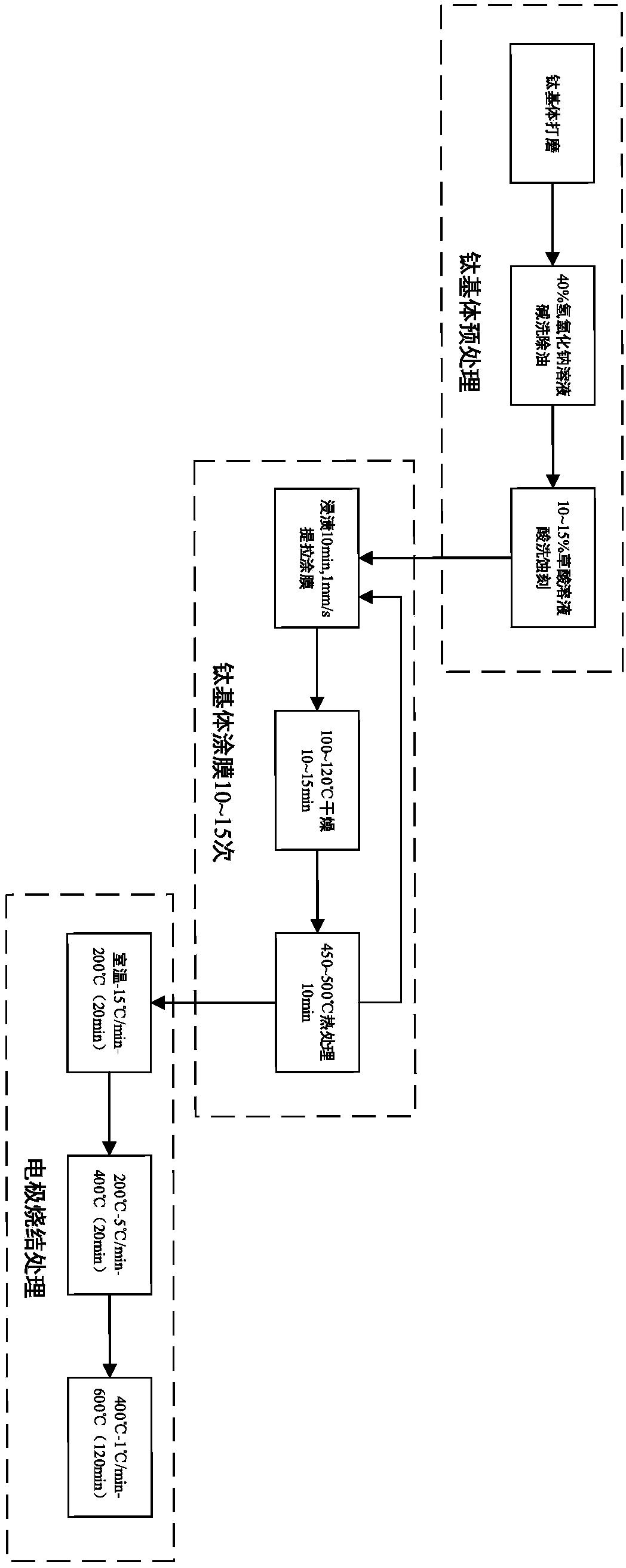

[0033] The invention is a preparation method of a novel molybdenum and antimony co-doped titanium-based tin dioxide electrocatalytic electrode, such as figure 1 As shown, the method steps are as follows:

[0034] (1) Pretreatment of the titanium substrate: the titanium substrate is polished with 120# and 240# water-resistant sandpaper, and then washed with a mass concentration of 40% NaOH solution at 80°C for 1 hour to remove oil, and then cleaned with a mass concentration of 10~15 % oxalic acid solution was etched in a slightly boiling state for 1 h, washed with distilled water and stored in ultrapure water.

[0035] (2) Preparation of sol: using ethanol as the solvent, the atomic molar ratio of Sn, Sb, and Mo is 100:3:1~3, and the source of the above elements is SnCl 4 · 5H 2 O, Sb 2 o 3 , (NH 4 ) 6 Mo 7 o 24 and other raw materials, add complexing agent citric acid and ethylene glycol, wherein the molar ratio of metal ion, citric acid and ethylene glycol is 1:3:3; m...

Embodiment 1

[0041] A method for preparing a novel molybdenum and antimony co-doped titanium-based tin dioxide electrocatalytic electrode, the steps are as follows:

[0042] (1) Pretreatment of the titanium substrate: the titanium substrate is polished with 120# and 240# water-resistant sandpaper, and then degreased with 40% NaOH solution at 80°C for 1 hour, and then etched with 10% oxalic acid solution in a slightly boiling state 1h, washed with distilled water and stored in ultrapure water.

[0043] (2) Preparation of sol: use ethanol as the solvent, the atomic molar ratio of Sn, Sb, and Mo is 100:3:1, and the source of the above elements is SnCl 4 · 5H 2 O, Sb 2 o 3 , (NH 4 ) 6 Mo 7 o 24 and other raw materials, adding complexing agent citric acid and ethylene glycol, wherein the molar ratio of metal ions, citric acid and ethylene glycol is 1:3:3. After the raw materials are completely dissolved, fully stir in a 60°C water bath for 1 hour, and then stand and age in a 60°C water ...

Embodiment 2

[0047] A method for preparing a novel molybdenum and antimony co-doped titanium-based tin dioxide electrocatalytic electrode, the steps are as follows:

[0048] (1) Pretreatment of the titanium substrate: the titanium substrate is polished with 120# and 240# water-resistant sandpaper, and then degreased with 40% NaOH solution at 80°C for 1 hour, and then etched with 15% oxalic acid solution in a slightly boiling state 1h, washed with distilled water and stored in ultrapure water.

[0049] (2) Preparation of sol: use ethanol as the solvent, the atomic molar ratio of Sn, Sb, and Mo is 100:3:2, and the source of the above elements is SnCl 4 · 5H 2 O, Sb 2 o 3 , (NH 4 ) 6 Mo 7 o 24 and other raw materials, adding complexing agent citric acid and ethylene glycol, wherein the molar ratio of metal ions, citric acid and ethylene glycol is 1:3:3. After the raw materials are completely dissolved, fully stir in a 60°C water bath for 1 hour, and then stand and age in a 60°C water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com