Corrugated-folded paper multistage sandwich energy absorption structure and preparation method thereof

A technology of energy-absorbing structures and origami structures, applied in chemical instruments and methods, protective equipment, and other household appliances, can solve problems such as insufficient energy absorption capacity, prone to structural instability, and single structural forms, so as to improve energy absorption Capacity, extension of compression and densification strain, and improvement of energy absorption stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing a corrugated-origami multi-stage sandwich energy-absorbing structure of the present invention, first draws the data model of the corrugated-origami multi-stage sandwich energy-absorbing structure, then slices the digital cross-section of the data model to obtain slice data, and slices the data Import a 3D printer, select metal powder raw materials according to the situation, and integrate processing and molding through a 3D printer to obtain a corrugated-origami multi-stage sandwich energy-absorbing structure. The specific steps are as follows:

[0042] S1. Determine the adjustable geometric parameters related to the corrugated-origami multi-stage sandwich energy-absorbing structure according to specific needs and actual conditions, draw the 3D data model of the structure through the commercial 3D modeling software SolidWorks, and convert the obtained 3D data model into STL format data and export;

[0043] Relevant adjustable geometric parameters ...

Embodiment 1

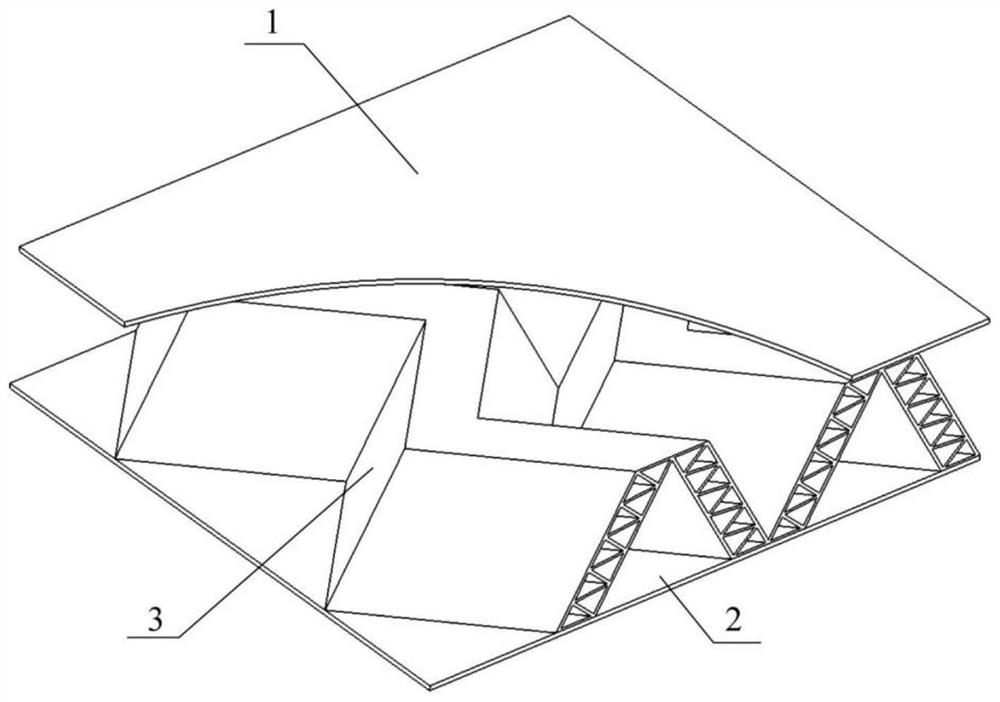

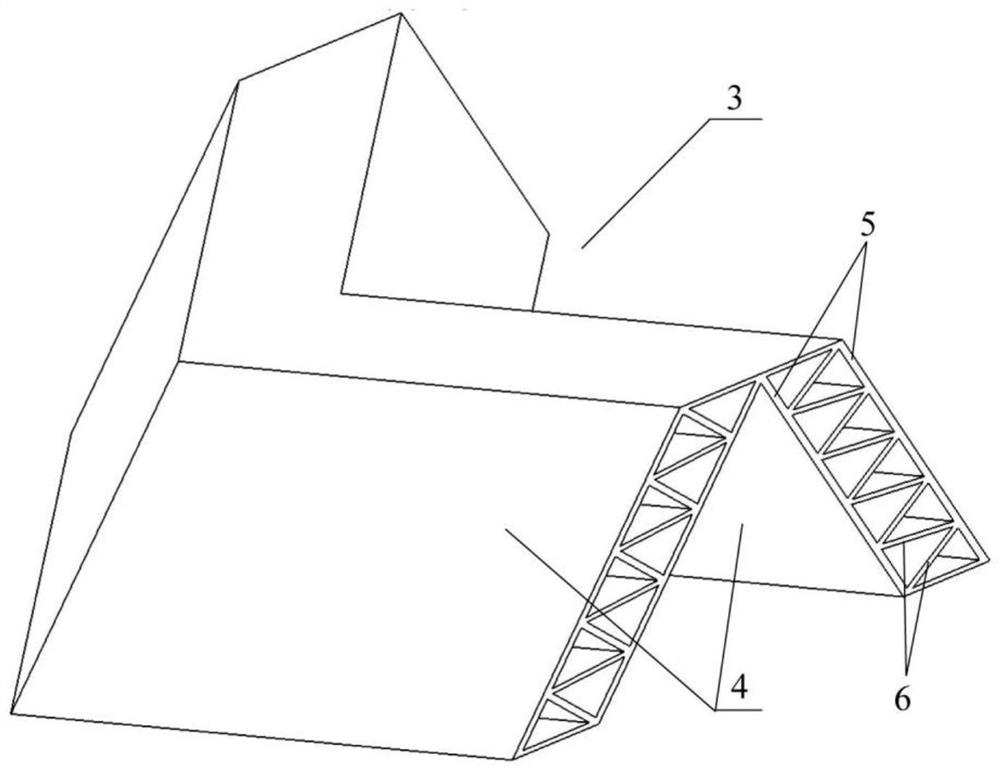

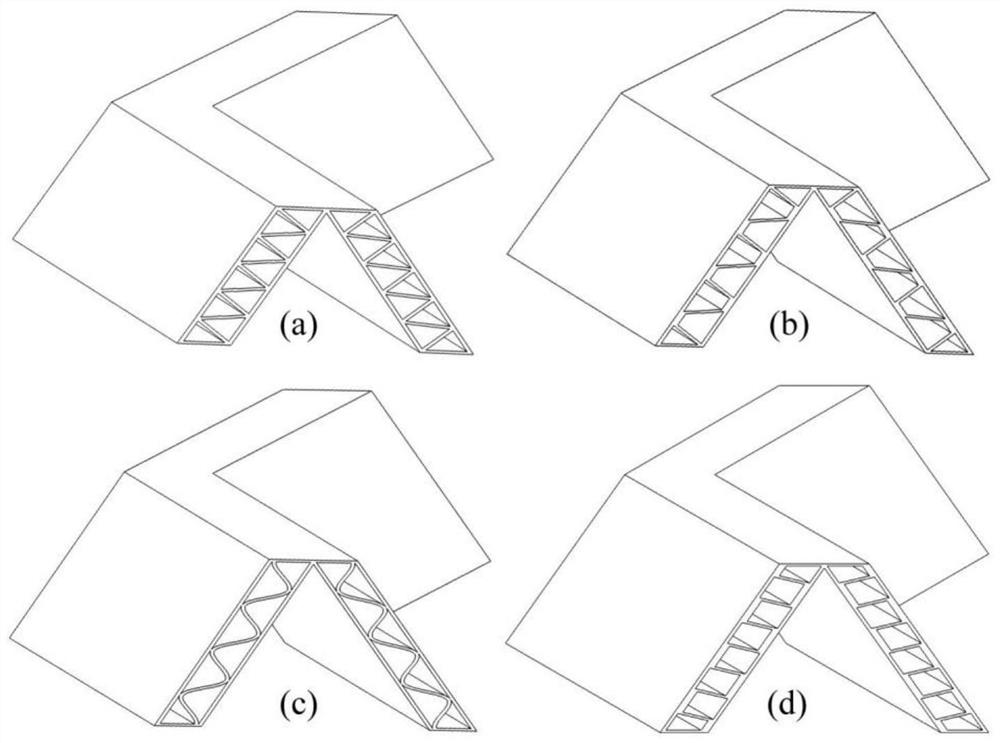

[0048] (1) Use the commercial 3D modeling software SolidWorks to draw the 3D data model of the corrugated-origami multi-stage sandwich energy-absorbing structure. The upper panel is a square plate with a side length of 60mm and a thickness of 1mm; the lower panel is a square plate with a side length of 60mm and a thickness of 1mm; the corrugated-origami multi-level structural unit cell forming the core part is shown in the following geometric model image 3 (a), the four ridges formed at the joints of the left and right adjacent corrugated sandwich panels form an acute angle of 60° with the upper and lower panels, and the angle of the "herringbone" shape in the top view is 90°; for the corrugated sandwich panels with secondary structure, the outer The wall thickness of the corrugated plate covering the panel and the core body is 1 mm, the corrugated core body is a 60° regular triangular corrugation, and the direction of the corrugated channel is horizontal. Convert the drawn 3...

Embodiment 2

[0052] (1) Use the commercial 3D modeling software SolidWorks to draw the 3D data model of the corrugated-origami multi-stage sandwich energy-absorbing structure. The upper panel is a square plate with a side length of 60mm and a thickness of 0.5mm; the lower panel is a square plate with a side length of 60mm and a thickness of 0.5mm; the corrugated-origami multi-level structural unit cell that forms the core part is shown in the following geometric model image 3 (b), the four ridges formed at the joints of the left and right adjacent corrugated sandwich panels form an acute angle of 30° with the upper and lower panels, and the angle of the "herringbone" shape in the top view is 60°; for the corrugated sandwich panels with secondary structure, the outer The wall thickness of the covering panel and the corrugated plate as the core is 0.5mm, the corrugated core is 60° isosceles trapezoidal corrugation, and the direction of the corrugated channel is horizontal. Convert the drawn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com