Concave mirror reflective-concentrating sun-locking heat-absorption type solar heat energy collecting method and device

A heat-absorbing device and sunlight technology, which is applied to solar thermal devices, solar thermal energy, heating devices, etc., can solve the difficult production technology of high-temperature heat-absorbing devices, insufficient adaptability to repeated changes in high and low temperature, and easy corrosion of mechanical rotating systems. and other problems, to achieve the effect of facilitating the design of thermal insulation devices, reducing structural strength requirements, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0198] Below, this design scheme is illustrated with specific examples.

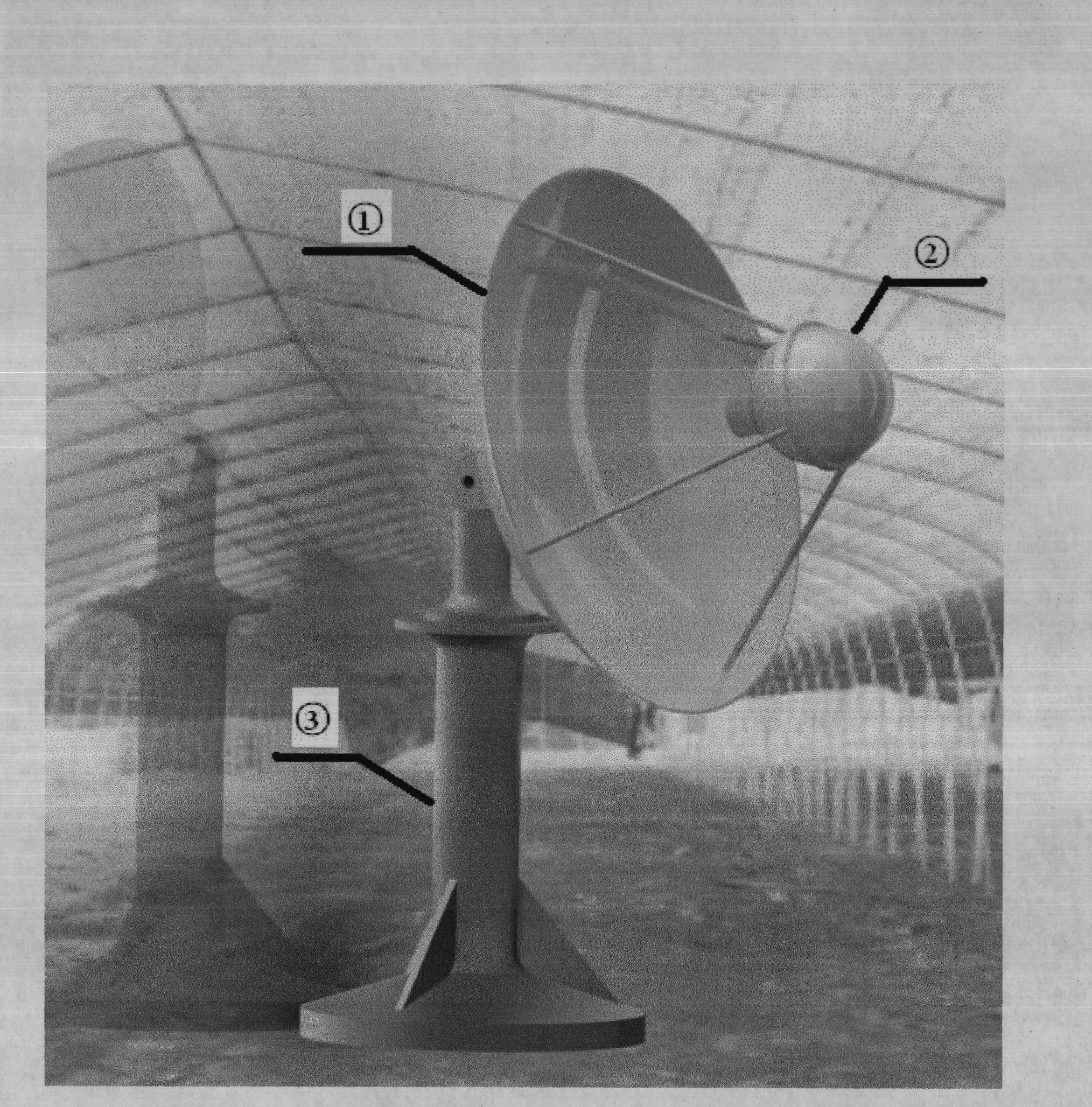

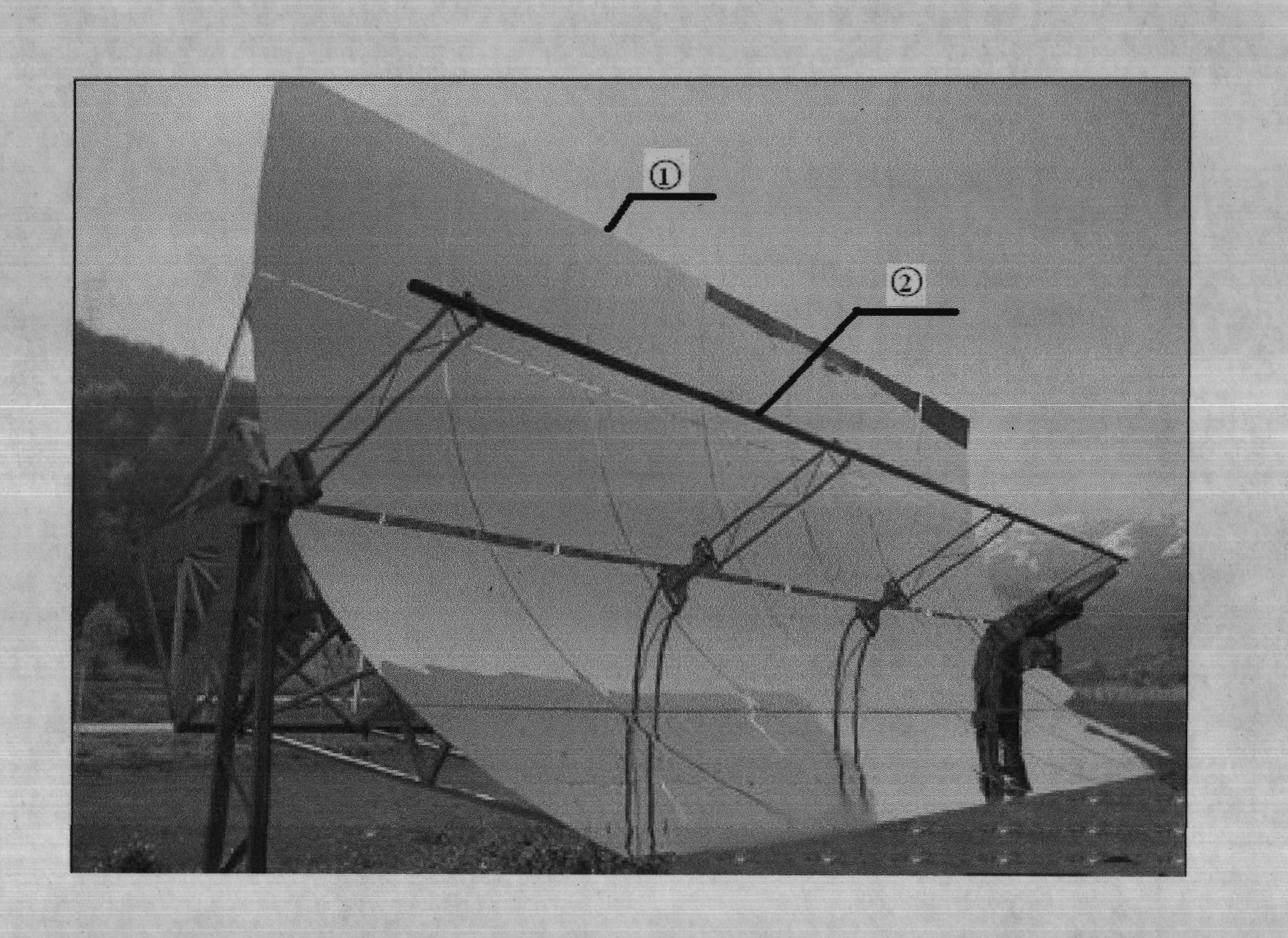

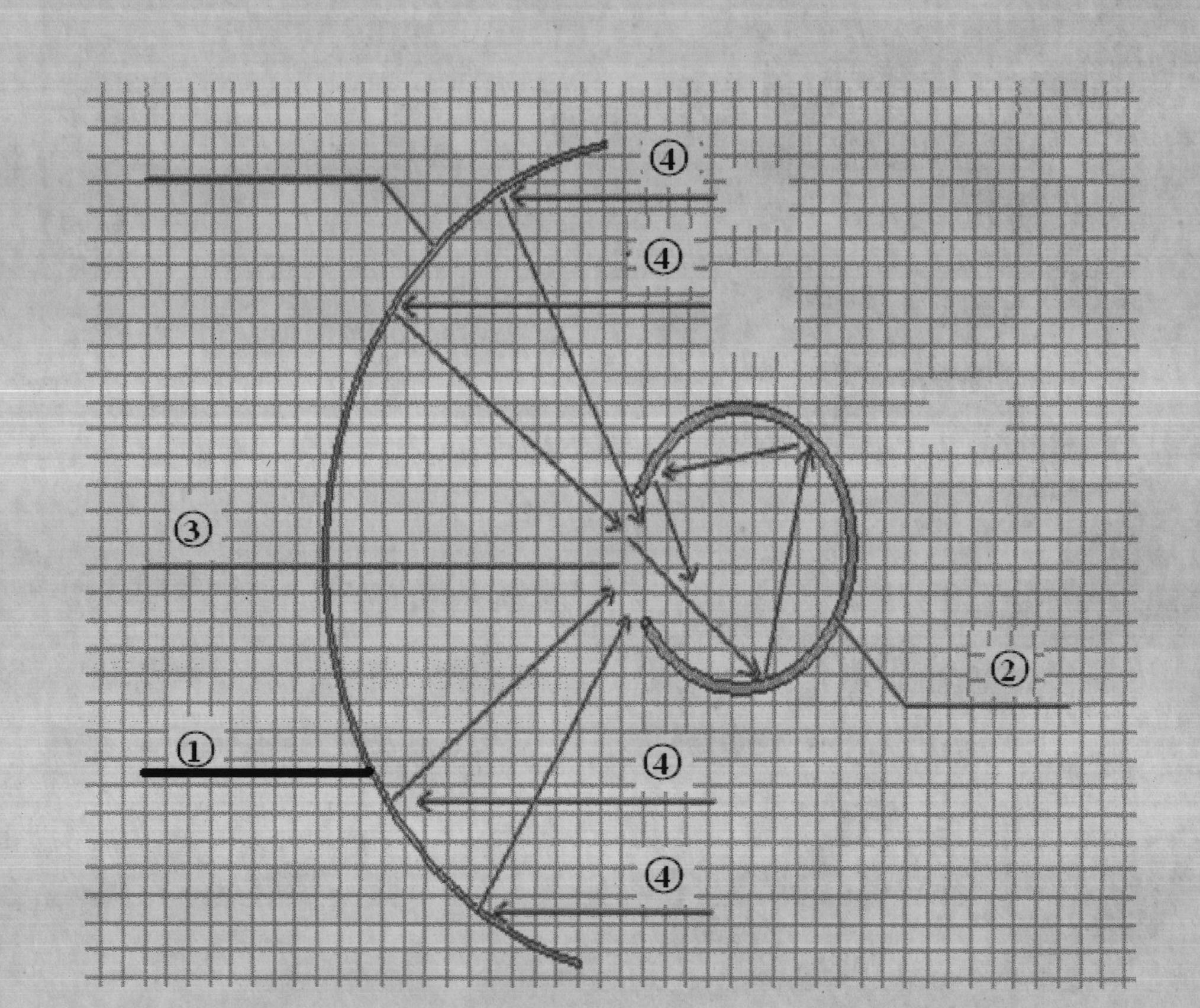

[0199] This example is a spherical glass shell made of glass material as a wind resistance device. The diameter of the concave mirror is 2 meters. The outer cover type concave mirror that generates high-temperature water vapor reflects the light-concentrating lock-yang heat-absorbing solar heat energy collection device.

[0200] The appearance and structure of this instance are as follows Figure 26 shown.

[0201] The diameter of the glass shell of this example is 2.3 meters and consists of four parts: glass top cover, glass, arc-shaped shell, and movable shell. Each part is made of 8MM thick ordinary flat glass, which is cut, drilled, heated, Bending, tempering, bonding and forming.

[0202] The glass top cover, glass, and arc-shaped shell are bonded into a whole by glass glue, and the movable shell is connected with these parts through a threaded connection with an elastic washer to form a spherical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com