Die assembling, die locking and die disassembling method of metal die casting machine in metal special forming technology and mechanism thereof

A mold clamping and mold splitting technology, which is applied in the field of metal die casting machine mold clamping, mold clamping and mold separation and its mechanism in the metal special forming technology, can solve the problems of no quantification, insufficient mold clamping, difficulty in manufacturing and installation, etc. Achieve the effects of simple control and operation, ensuring safety without overloading, and convenient design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

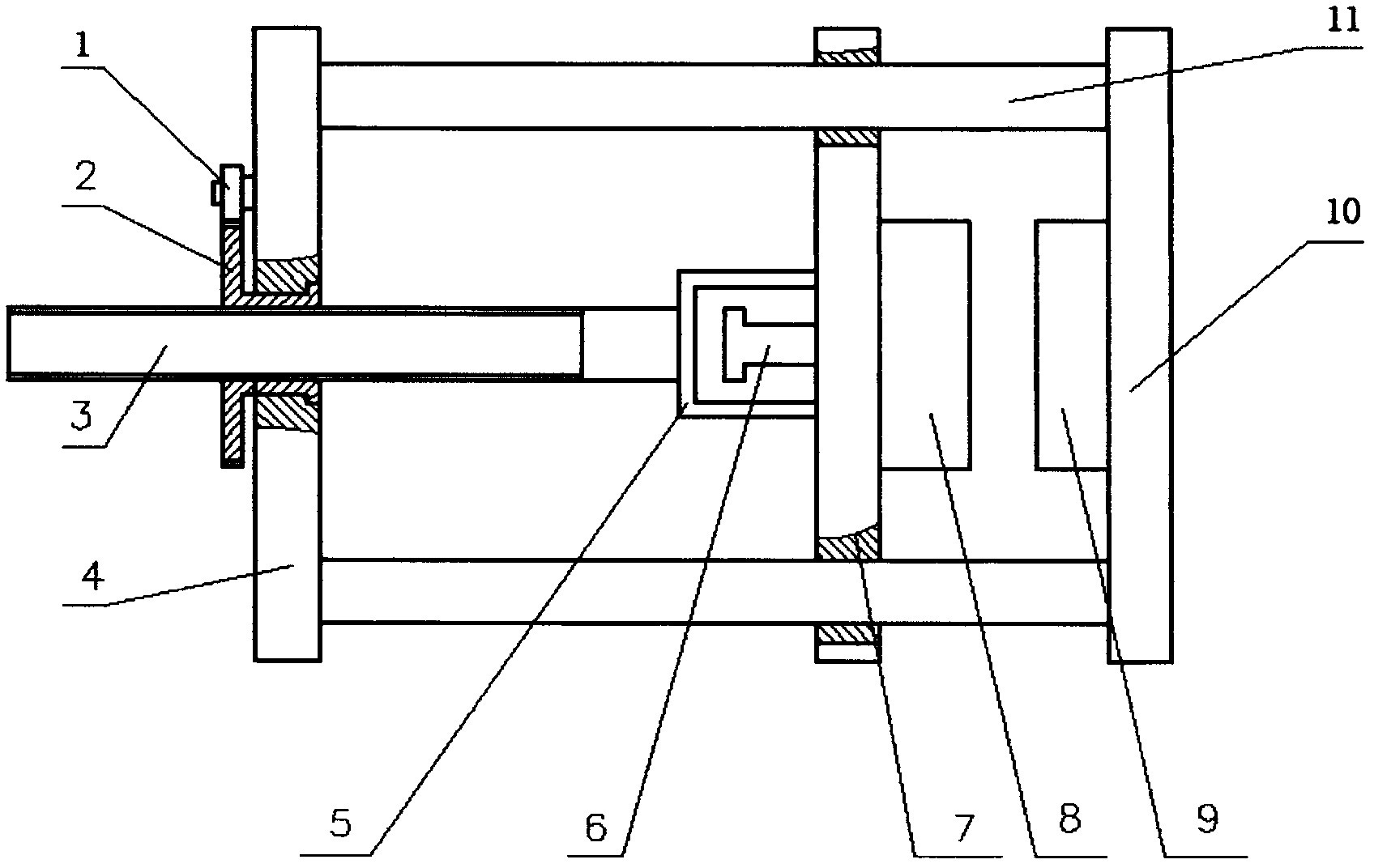

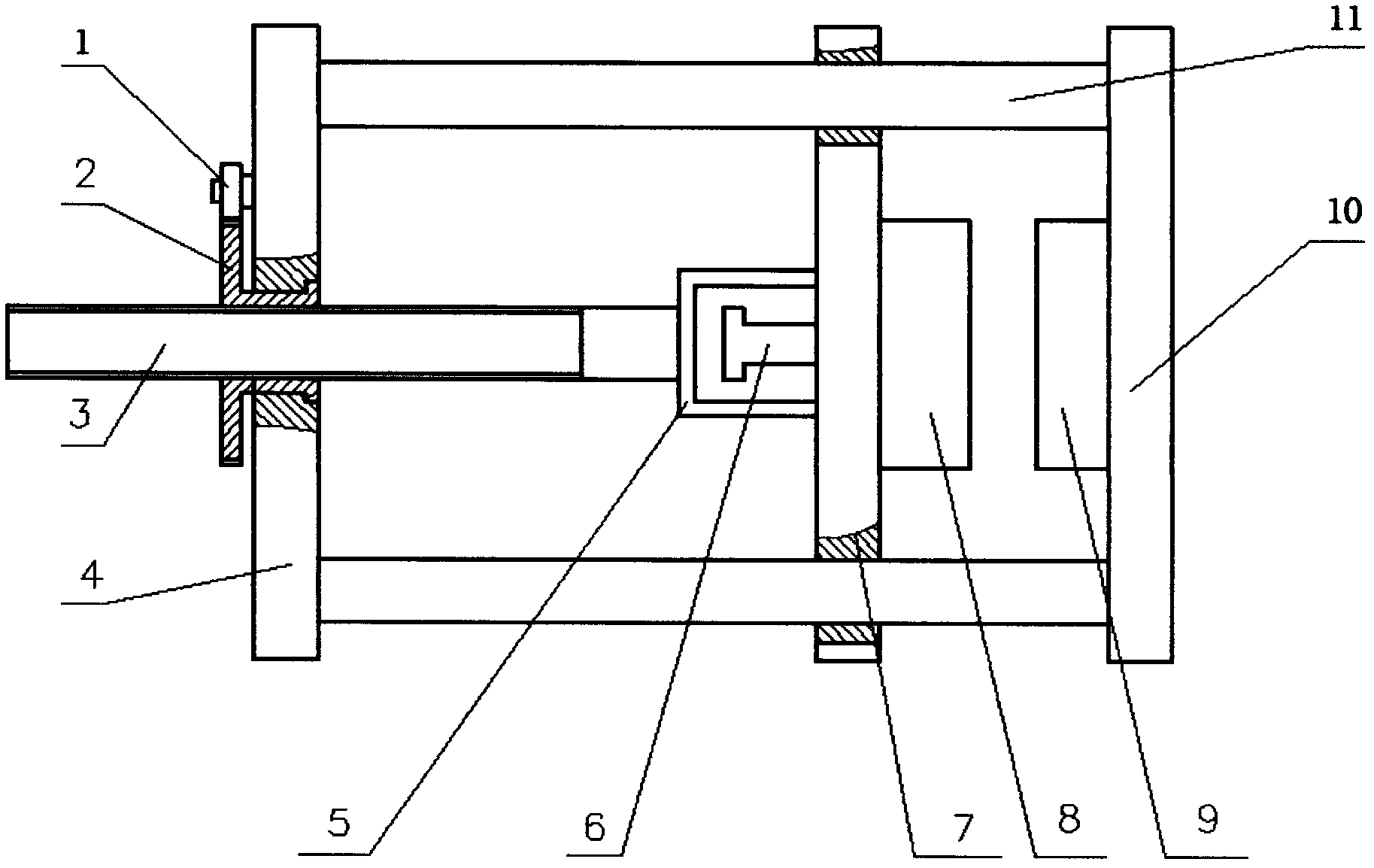

[0010] Four symmetrically distributed tie rods 11 are arranged between the rear plate 4 and the fixed plate 9 of the die-casting machine to form a frame. The movable template 7 is empty and can move on the pull rod 11. In 1 or 2 holes of the rear plate 4, a gear nut 2 that can be idling is set, and a thrust screw 3 is arranged in the gear nut 2, and the other end of the thrust screw 3 is consolidated with the supporting frame 5 above the movable template 7. A two-speed hydraulic motor 1 is arranged on the outer side of the rear plate 4 . The hydraulic motor 1 drives the gear nut 2 to rotate through the gear. The gear nut 2 that can only rotate and cannot move quickly drives the thrust screw 3 and the movable template 7 to move close to the fixed template 9 to realize the mold clamping of the movable module 8 and the fixed module 10, and then change to a low-speed drive until the movable template 7 is inside the movable module 8 It is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com