Flexible printed circuit board and method for manufacturing same

A circuit substrate, flexible printing technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of inability to effectively maintain work reliability, increase the thickness of the circuit board, and complex manufacturing processes, to simplify the line width, manufacturing The effect of easy process and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

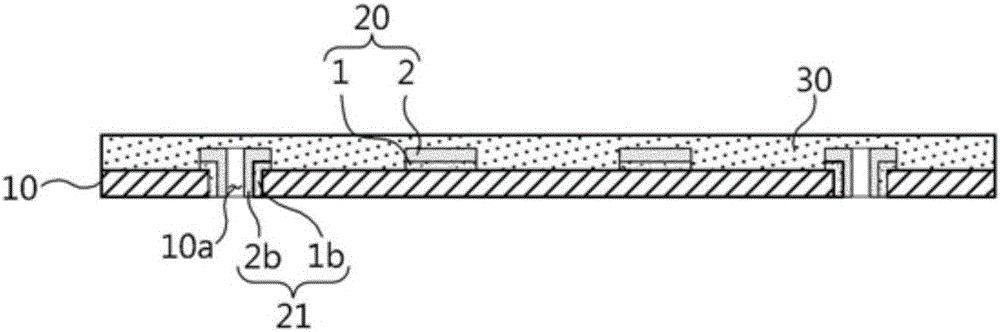

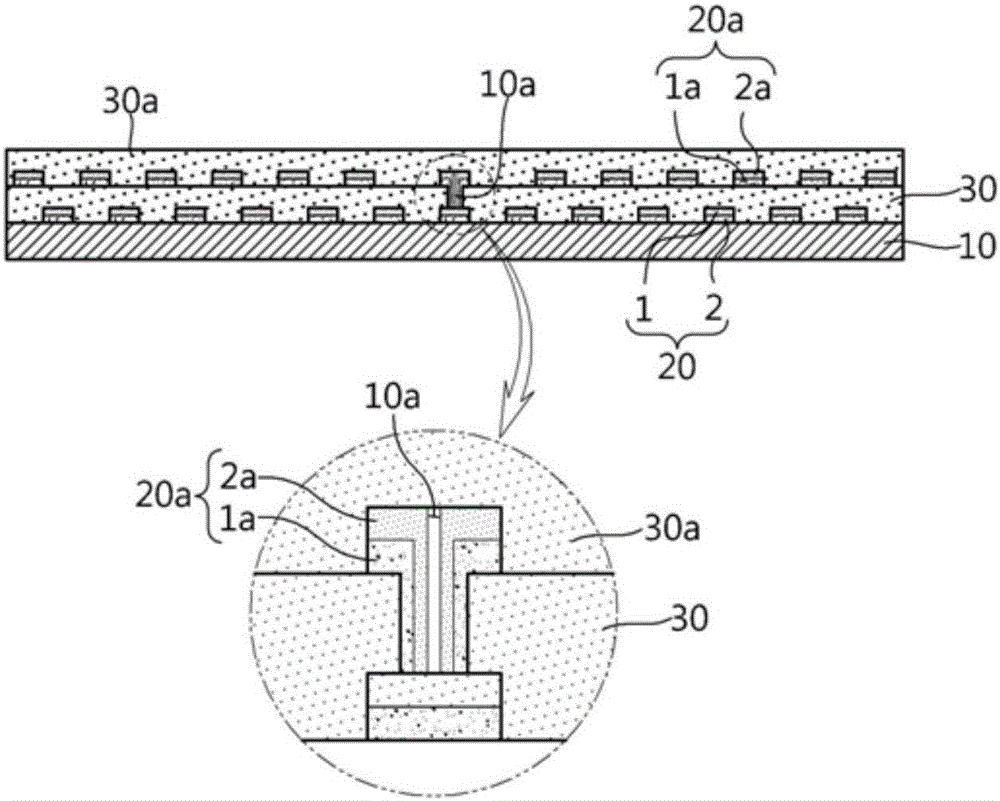

[0054] The following will describe in detail with reference to the accompanying drawings of the present invention. Throughout the specification, detailed descriptions of redundant parts and related known technical features and functions that may make the subject matter of the present invention unclear will be omitted. The present invention is provided so that those skilled in the art can implement the technical idea of the present invention. Therefore, in order to clearly describe the present invention, the shapes, dimensions, etc. of constituent elements in the drawings may be exaggerated.

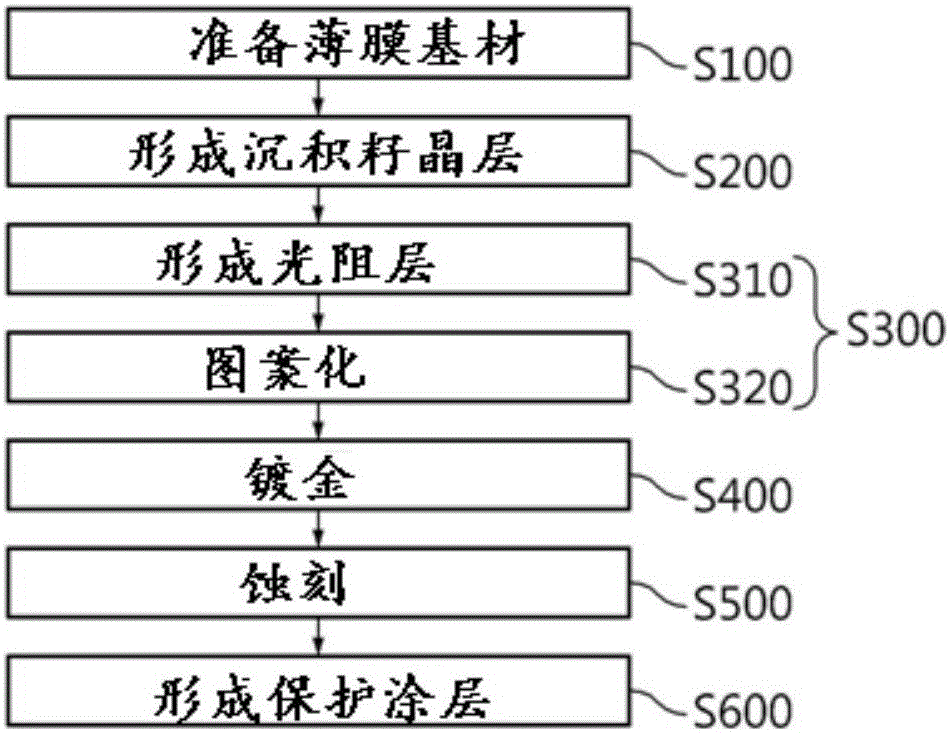

[0055] Figure 1 to Figure 7 The line widths of the circuit pattern 20 and the intervals therebetween are shown in order to clearly illustrate the components of the present invention, and are different from the actual situation. In the process of implementing the flexible printed circuit board and its manufacturing method according to the present invention Among them, based on the lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com