Cutting fluid cooling device for five-axis numerical control machine tool

A technology for CNC machine tools and cooling devices, which is applied to metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. The effect of economical use and convenient centralized collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

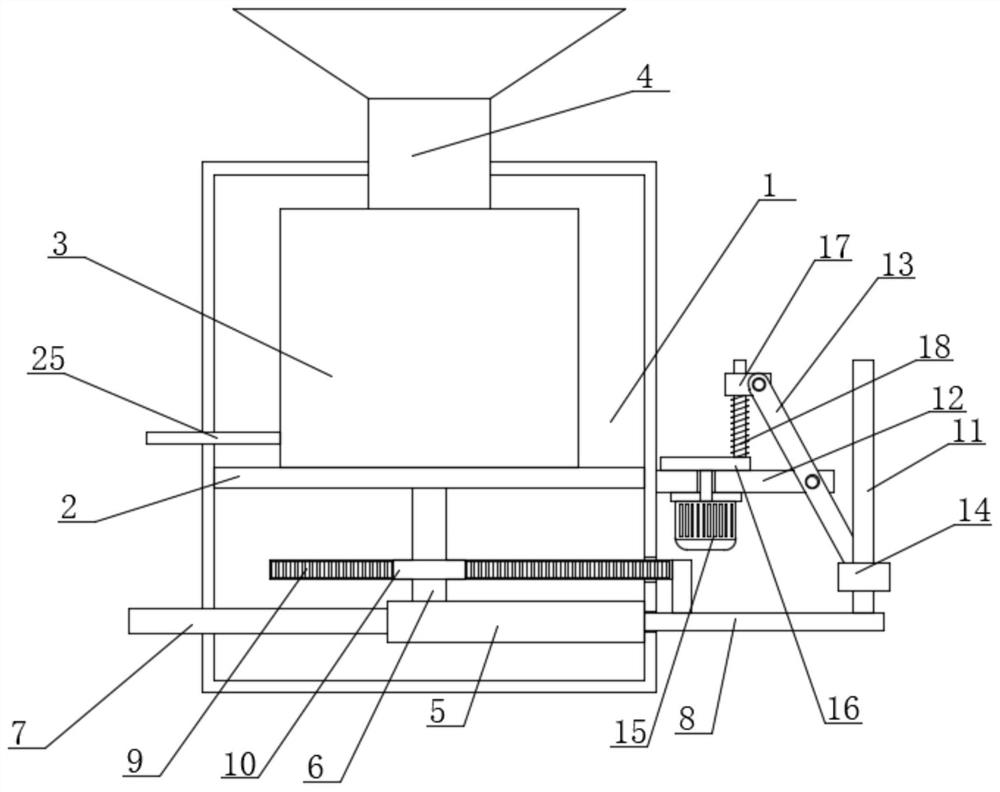

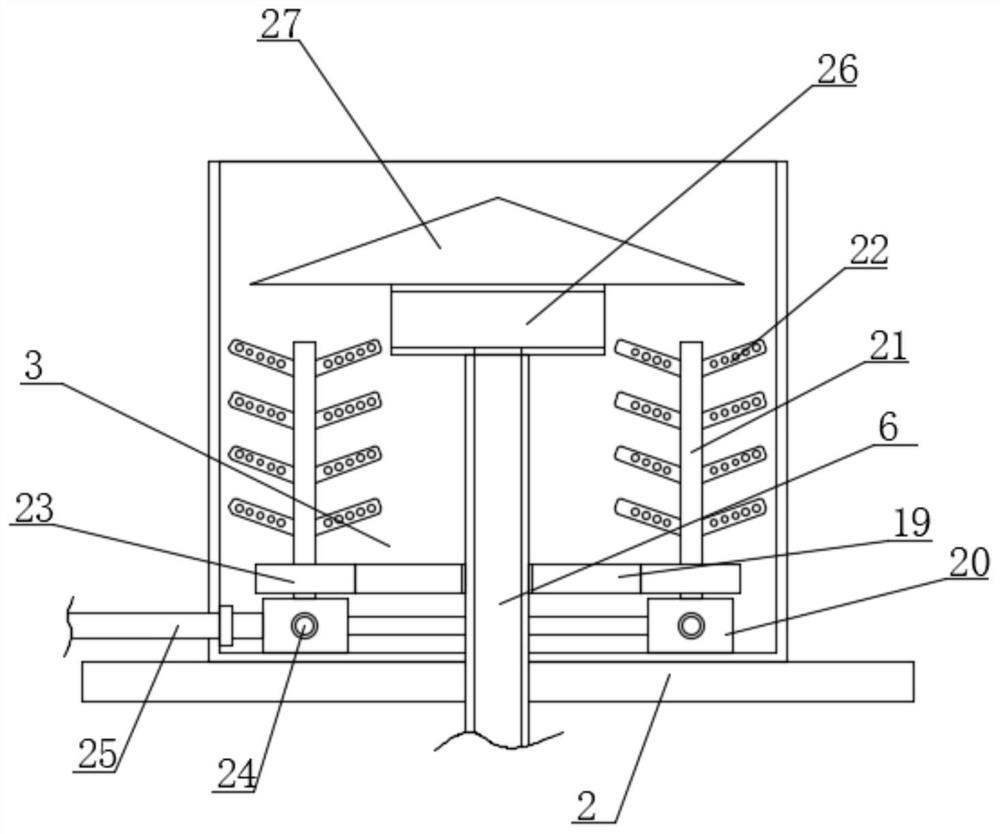

[0032] refer to Figure 1-7In this embodiment, a cutting fluid cooling device for a five-axis CNC machine tool is proposed, including an installation box 1, a support plate 2 is fixedly installed on the inner wall of the installation box 1, and the cooling box 3 can be stably supported by the support plate 2 , and the top of the support plate 2 is fixedly installed with a cooling box 3, and a plurality of cooling assemblies are installed in the cooling box 3, and the cooling assembly can be used to cool the cooling liquid. 4. The large opening area of the conical tube 4 can facilitate the collection of the coolant into the cooling box 3, and the top of the conical tube 4 extends above the installation box 1, and the bottom inner wall of the cooling box 3 rotates A rotating tube 6 is connected, and the rotating tube 6 is connected with a plurality of cooling components with the same connecting component, and the connecting component can realize the transmission of multiple co...

Embodiment 2

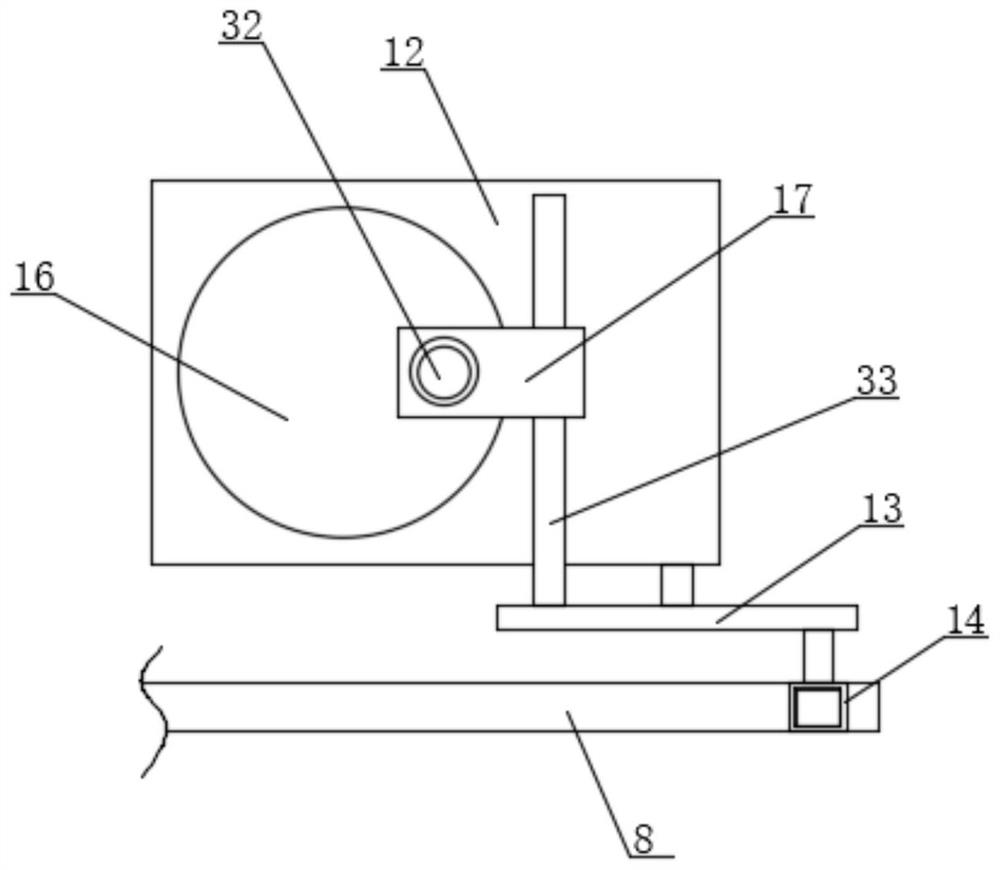

[0037] On the basis of Embodiment 1, the difference of this embodiment is that: the infusion set includes a mounting cover 5, a first one-way valve 29, a second one-way valve 30 and a transmission rod 8, and the mounting cover 5 is fixedly installed in the mounting box 1, the installation cover 5 can provide a good airtight environment for the principle of negative pressure suction, and the bottom end of the rotating tube 6 extends into the installation cover 5 and is connected with the top inner wall of the installation cover 5 in a sealed rotation. The right end of 7 extends into the installation cover 5 and is sealed and fixedly connected with the right side inner wall of the installation cover 5. The first one-way valve 29 is fixedly installed on the bottom end of the rotating tube 6, and the second one-way valve 30 is fixedly installed on the liquid outlet. At the right end of the pipe 7, the directional flow of the coolant can be realized by using the first one-way valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com