Dump truck frame with function of auxiliary frame

A technology for dump trucks and sub-frames, which is applied to vehicle components, substructures, spare tire layout and other directions, can solve problems such as unfavorable economy, high production costs, and increased vehicle curb weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

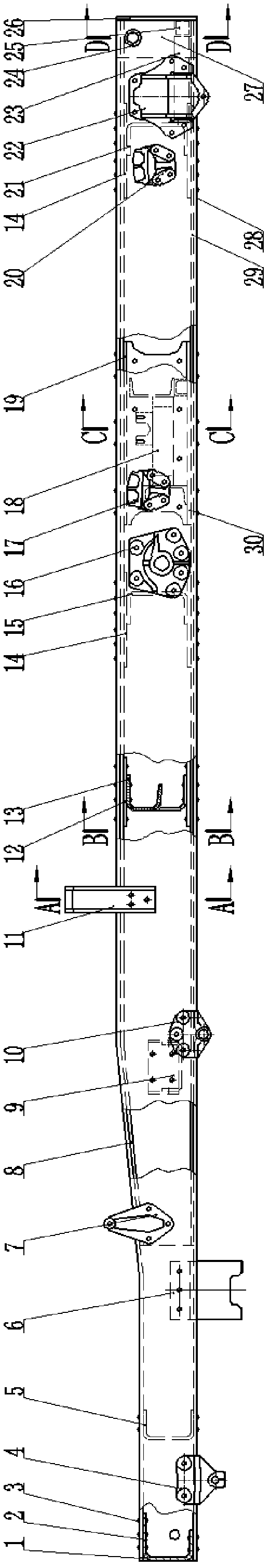

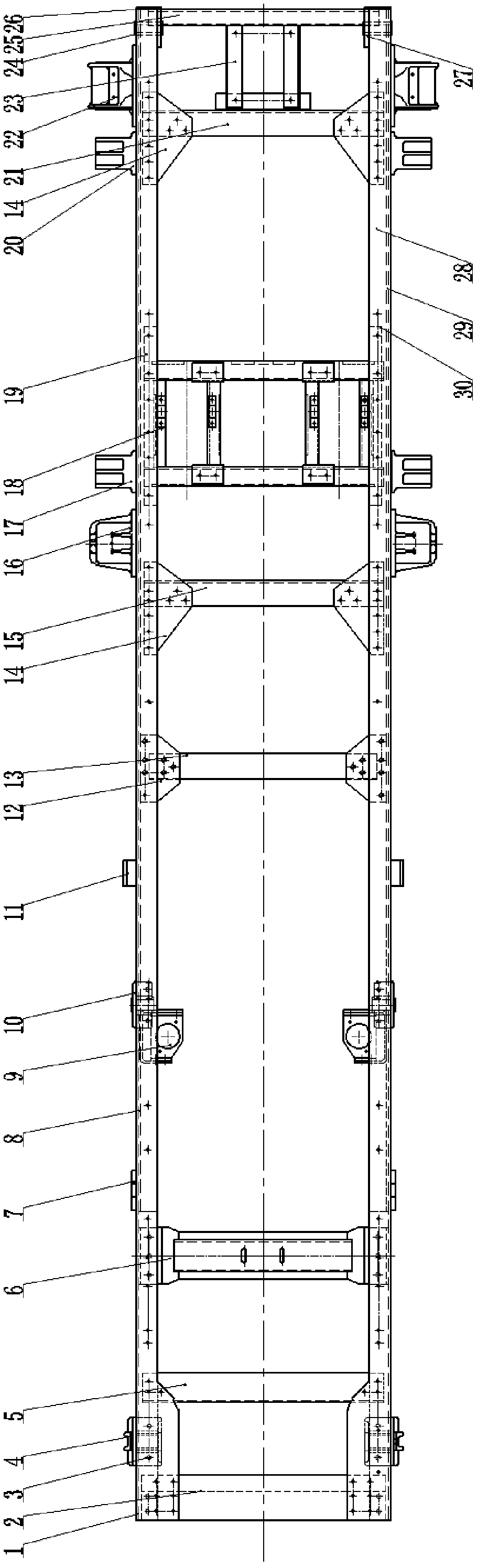

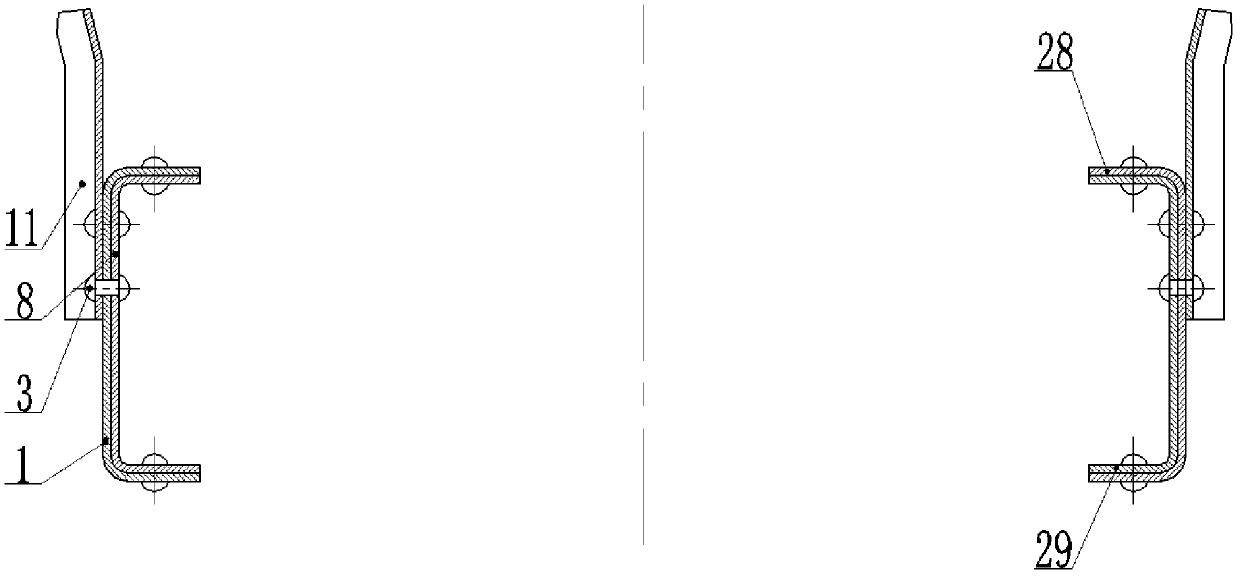

[0013] A detailed description will be given below in conjunction with the accompanying drawings.

[0014] Such as Figure 1~6 As shown, the right longitudinal beam 1 of the vehicle frame and the left longitudinal beam 28 of the vehicle frame are pressed into channel-shaped beams with unequal cross-sections with special girder steel plates. Use the rivet 3 to rivet the right trough-shaped reinforcing beam 8 of unequal cross-section formed by pressing and forming the special beam steel plate; the middle section and the rear section of the left longitudinal beam 28 of the frame where the force is relatively large, use the rivet 3 on the inner side to press the special beam steel plate for riveting The formed left trough-shaped reinforcing beam 29 of unequal cross-section is riveted on the inner side of the hydraulic cylinder at the right longitudinal beam 1 of the vehicle frame, and a right hydraulic cylinder support reinforcement plate 19 is pressed into a groove shape with a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com