Dump truck frame with function of auxiliary frame

A technology for dump trucks and subframes, which is applied to vehicle components, substructures, spare tire layout, etc., can solve problems such as unfavorable economy, increased vehicle curb weight, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

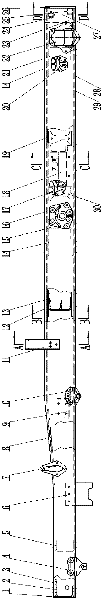

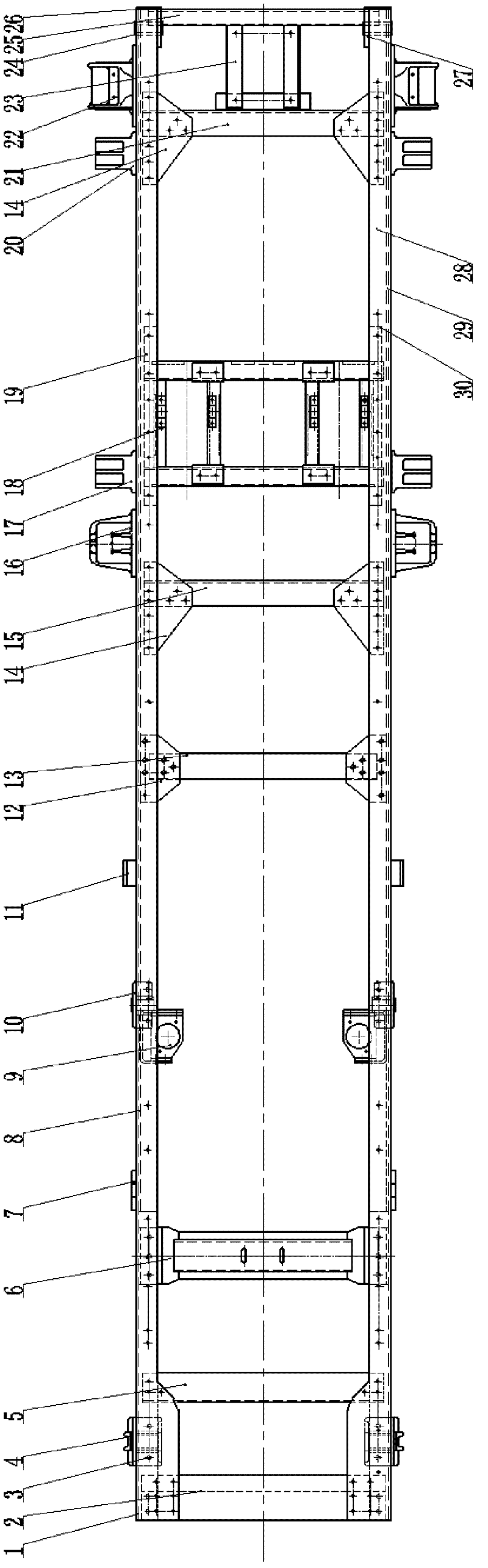

[0013] Detailed description will be given below in conjunction with the drawings.

[0014] Such as Figure 1~6 As shown, the right side member 1 of the frame and the left side member 28 of the frame are pressed into channel beams with unequal cross-sections with special beam steel plates. The middle and rear sections of the right side member 1 of the frame are subjected to greater force on the inner side. Use rivets 3 to rivet the right channel-shaped reinforcing beam 8 with unequal cross-sections formed by pressing special beam steel plates; the middle and rear sections of the left side member 28 of the frame are subject to greater stress, and rivets 3 are used on the inner side to be riveted with special beam steel plates. The formed left trough-shaped reinforcement beam 29 with unequal cross-section is installed on the right side member 1 of the frame, and a right hydraulic cylinder support reinforcement plate 19 is riveted on the inner side of the right side beam 1 and presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com